Food grade lactic acid bacteria active carrier Group A rotavirus vaccine and preparation method thereof

A group A rotavirus, lactic acid bacteria technology, applied in the direction of antiviral agents, viral antigen components, drug combinations, etc., to achieve the effects of low cost, stable properties, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Example 1: Codon optimization of antigen-encoding genes

[0053] Because rotavirus genes are expressed in eukaryotic cells, their codon usage preference is different from that of lactic acid bacteria. In order to successfully express the rotavirus gene in lactic acid bacteria cells, it is necessary to optimize its nucleotide sequence and remove rare codons. Its optimization principle is:

[0054] TTC→TTT; GTA→GTT; TCC→TCT; GAG→GAA; TGC→TGT; AGA→CGT; AGG→CGT

[0055] 1) Taking the gene encoding the VP4 protein of human rotavirus G2 serotype as an example, its optimized nucleotide sequence is as follows, and the two underlined parts are the sequences of VP8* and VP5* in sequence:

[0056] GCA AGT TTG ATT TAT CGT CAG CTG TTA ACC AAT TCA TAT TCT GTT GAT CTG CAC GAT GAA ATC GAA CAA ATC GGT AGC GAA AAG ACC CAG AAC GTG ACG ATT AAT CCG GGC CCA TTT GCG CAA ACC CGT TAT GCC CCG GTT AAC TGG CGC CAT GGT GAA ATT AAT GAT TCA ACC ACG GTT GAA CCA GTG CTG GAT GGC CCG TAT CAG CC...

Embodiment 2

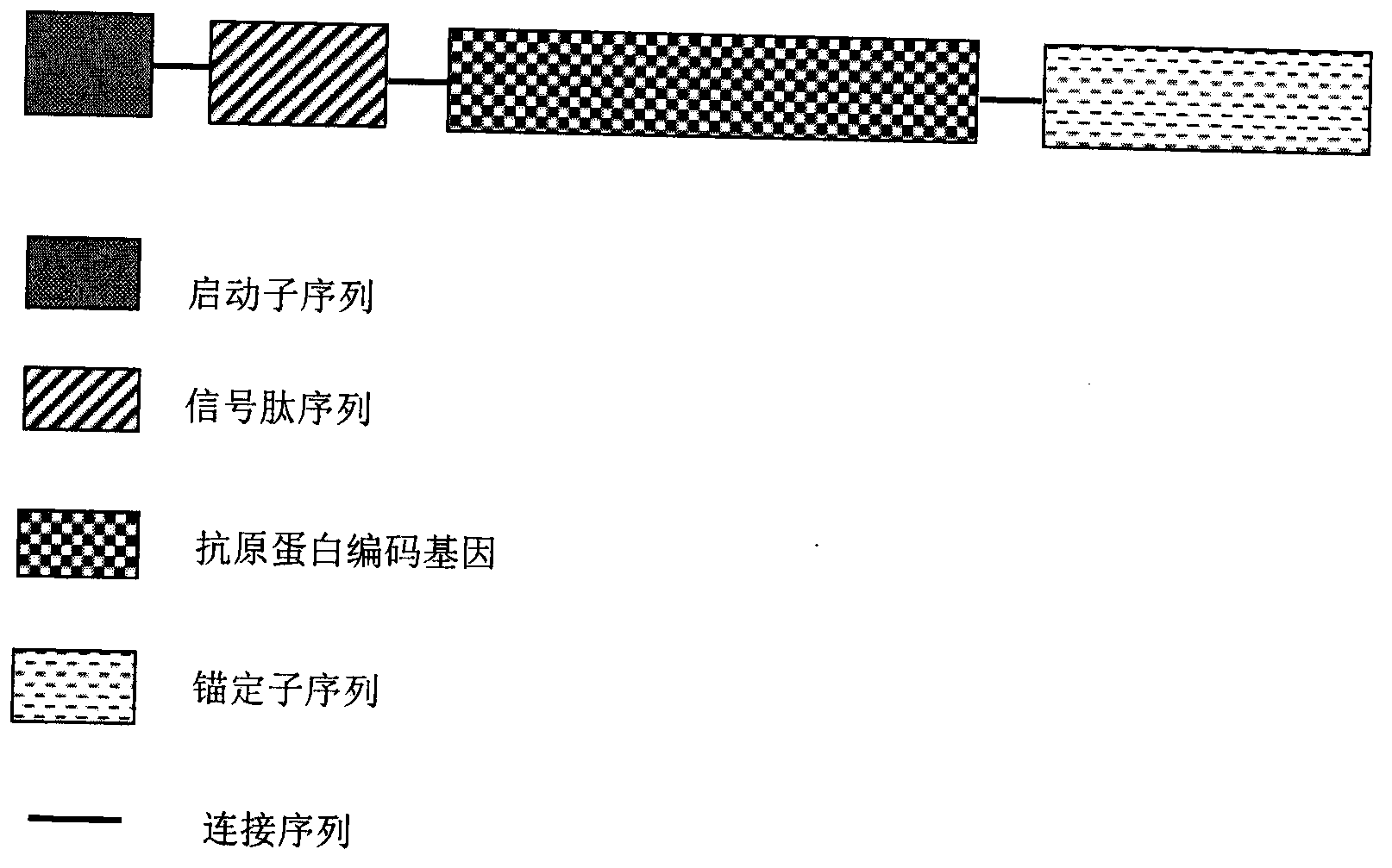

[0064] Embodiment 2: Construction of antigenic protein or vaccine adjuvant protein expression cassette

[0065] The expression and localization of antigenic protein or vaccine adjuvant protein is realized through the combined use of multiple expression control elements. These expression control elements include promoters, signal peptide sequences, antigen-encoding genes, anchor subsequences, and linking sequences between each expression control element (see appendix figure 1 ).

[0066] 1) In the present invention, the expression of the antigenic protein is ultimately controlled by a constitutive promoter. The constitutive promoter is derived from the Lactobacillus rRNA promoter, and is one of the following sequences, or one of the sequences with a similarity of more than 85% to the following sequences:

[0067] a) GTC GGT CGA GTT GTT GAC AGG ATA AAG GTC GCC TGG TAT GGT CTC AATATA GCG

[0068] b) GTC GTG GCA GTT GTT GAC AAC CTG TGG GCG GTT TGA TTT GTT CTT GCTATA GCG

[0069]...

Embodiment 3

[0096] Example 3: Human rotavirus P12 serotype VP7 protein expression cassette inserted into Lactobacillus fermentum chromosome, and antibiotic resistance gene removed

[0097] The Lactobacillus described in this example specifically refers to Lactobacillus fermentium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com