A kind of artificial pink diamond and its manufacturing method

A pink and diamond technology, applied in the field of jewelry and handicraft production, can solve the problems of weak fire, difficult production, low refractive index, etc., and achieve the effect of strong fire, low production cost and high refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

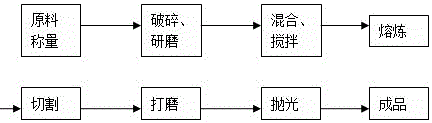

[0031] Embodiment 1: as shown below, production raw material and proportioning are:

[0032] PbO: 10-30%

[0033] Na 2 CO 3 : 15-20%

[0034] CaCO 3 : 25-40%

[0035] Cu: 5-15%

[0038] Preparation steps and process parameters are:

[0039] (1) Weigh various raw materials as required;

[0040] (2) Crushing and grinding blocky raw materials;

[0041] (3) Put various raw materials into the container and mix and stir to make the ingredients uniform;

[0042] (4) Pour the uniformly mixed raw materials into the crucible and put them into the smelting furnace for smelting. The characteristics are: put the raw materials into the crucible, put them into the smelting furnace at room temperature, and raise the temperature with the furnace; the maximum heating temperature is 1080 ° C, and the heat preservation 3 hours; cooling with the furnace, the furnace door is always closed during the cooling process;

[0043] (5...

Embodiment 2

[0045] Embodiment 2: as shown below, production raw material and proportioning are:

[0046] SiO 2 : 20-40%

[0047] Na 2 CO 3 : 15-20%

[0048] CaCO 3 : 25-40%

[0049] Cu: 5-15%

[0050] Magnesium oxide: 5-15%

[0051] Aluminum oxide or aluminum hydroxide: 5-15%

[0052] Zinc oxide: 5-15%

[0053] Preparation steps and process parameters are:

[0054] (1) Weigh various raw materials as required;

[0055] (2) Crushing and grinding blocky raw materials;

[0056] (3) Put various raw materials into the container and mix and stir to make the ingredients uniform;

[0057] (4) Pour the uniformly mixed raw materials into the crucible and put them into the smelting furnace for smelting. The characteristics are: put the raw materials into the crucible, put them into the smelting furnace at room temperature, and heat up with the furnace; the maximum heating temperature is 1150 ° C, and the heat preservation 3 hours; cooling with the furnace, the furnace door is always clos...

Embodiment 3

[0060] Embodiment 3: as shown below, production raw material and proportioning are:

[0061] ZrO 2 : 15-30%

[0062] SiO 2 : 20-40%

[0063] Na 2 CO 3 : 15-20%

[0064] Cu: 5-15%

[0065] Magnesium oxide: 5-15%

[0066] Aluminum oxide or aluminum hydroxide: 5-15%

[0068] Preparation steps and process parameters are:

[0069] (1) Weigh various raw materials as required;

[0070] (2) Crushing and grinding blocky raw materials;

[0071] (3) Put various raw materials into the container and mix and stir to make the ingredients uniform;

[0072] (4) Pour the uniformly mixed raw materials into the crucible and put them into the smelting furnace for smelting. The characteristics are: put the raw materials into the crucible, put them into the smelting furnace at room temperature, and raise the temperature with the furnace; the maximum heating temperature is 1250 ℃, and the heat preservation 3 hours; cooling with the furnace, the furnace door is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com