An Optical-Magnetic Coupling Method for Improving Plastic Deformation Ability of Aluminum Matrix Composites

An aluminum matrix composite material and plastic deformation technology, which is applied in the field of optical magnetic coupling of aluminum matrix composite materials to improve the plastic deformation ability of aluminum matrix composite materials, can solve the problems of material size deformation, tissue deformation and large residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

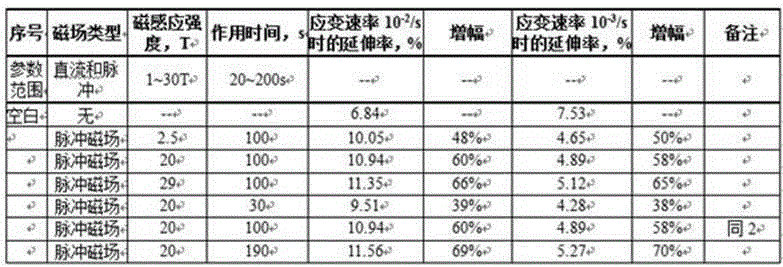

[0032] Embodiment one: (Al 3 Zr (s) +Al 2 O 3(s) ) p Preparation of / 7055 Aluminum Matrix Composites and Characteristics of Plastic Deformation under Different Conditions

[0033] The characteristics of this aluminum matrix composite material are: Al 3 Zr、Al 2 o 3 Particle-reinforced 7055 aluminum-based composite material is a micro-nano particle-reinforced deformable aluminum-based composite material. The material preparation method is: melting 7055 aluminum alloy (Zn: 8.4%, Cu: 2.2%, Mg: 2.4%, Zr: 0.2%, average is the mass percentage, and the rest is aluminum), using zirconium carbonate powder as raw material, through the reaction with aluminum liquid to generate Al 2 o 3 , Al 3 Zr particles, the total particle fraction is designed to be 4vol.%, according to the metering equation of formula (1), and according to the experimental setting of zirconium carbonate reaction yield of 75%, then 4vol.% (Al 2 o 3 +Al 3 Zr) The amount of zirconium carbonat...

Embodiment 2

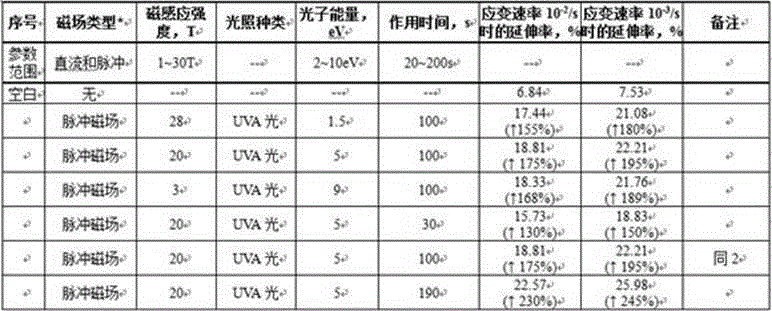

[0044] Example 2: High plasticity TiB 2 Particle Reinforced Cast Aluminum Matrix Composites

[0045] The characteristics of this aluminum-based composite material are: micro-nano particle reinforced cast aluminum-based composite material, and the material preparation method is: smelting A356 aluminum alloy (Si: 7%, Mg: 0.3%, both are mass percentages, and the rest is aluminum ), to potassium fluorotitanate K 2 TiF 6 and potassium fluoroborate KBF 4 As a reaction salt, the particle volume fraction is designed to be 3vol.%. According to the reaction measurement equation of formula (2), the potassium fluorotitanate K is set according to the experiment. 2 TiF 6 and potassium fluoroborate KBF 4 The yield rate is 90%, then generate 3vol.%TiB 2 Reinforced particles need to add K 2 TiF 6 The amount is 18.6% (mass percentage) of the aluminum in the base alloy, and the KBF that needs to be added 4 The amount is 19.5% (mass percentage) of the amount of aluminum in the base...

Embodiment 3

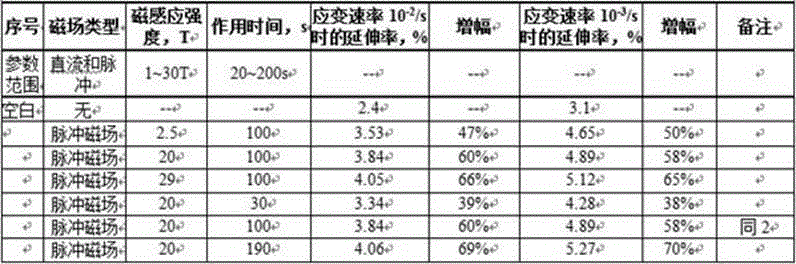

[0055] Example 3: High plasticity SiC fiber reinforced 2024 aluminum matrix composite material

[0056] The characteristics of this aluminum matrix composite material are: fiber reinforced deformed aluminum matrix composite material. , and the rest is Al) into the fixed cavity of the built-in SiC fiber prefabricated part by liquid force, the pressure used is 20MPa, the pressure is applied until the end of solidification, and the SiC fiber reinforced 2024 aluminum matrix composite is prepared, and the fiber volume fraction is controlled at 5vol. %, SiC density 3.17×10 3 kg / m 3 , then the quality of SiC fiber added is 6.4% (mass percentage) of the aluminum content in the alloy. The sample is a cube with a size of 100mm×100mm×100mm. The sample is rolled three times to form a thin plate with a thickness of 10mm. , the thin plate was subjected to heat treatment at 490°C for 3h and aging at 190°C for 10h, and then the comparative experiments of "magnetic field plastic deformatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com