High-toughness boron-containing carbon structural steel sheet coil and production method thereof

A technology of structural steel plate and production method, which is applied in the field of carbon structural steel and low alloy steel, can solve problems such as insufficient elongation and strength performance, tensile fracture delamination, impact fracture delamination, etc., to avoid insufficient elongation performance, microstructure Uniform, good low temperature impact toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

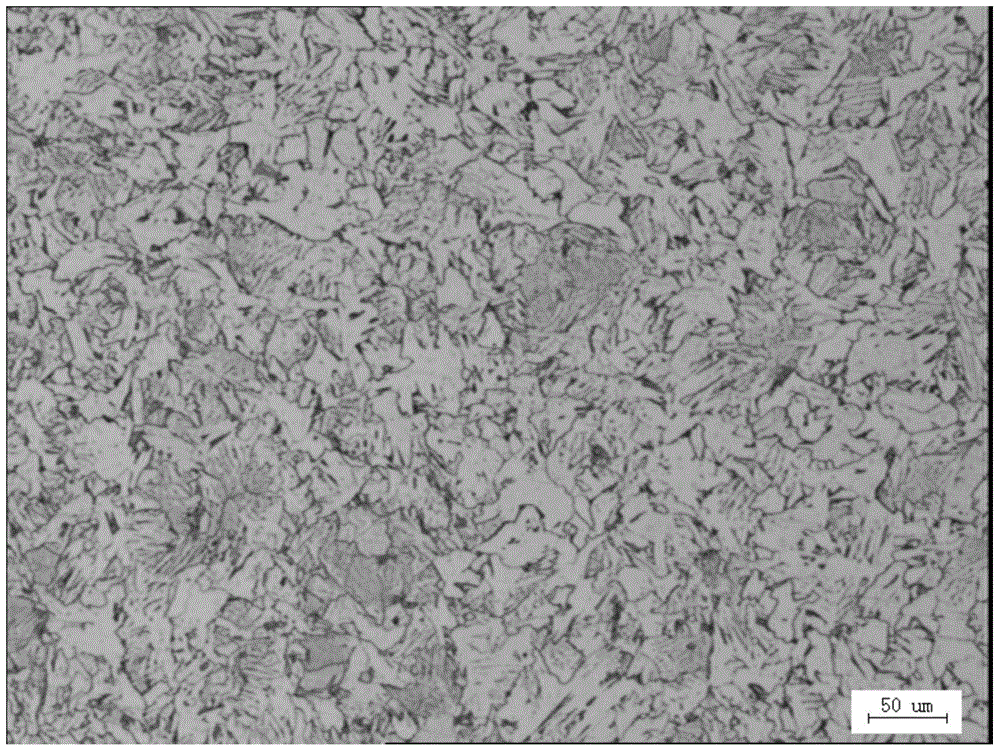

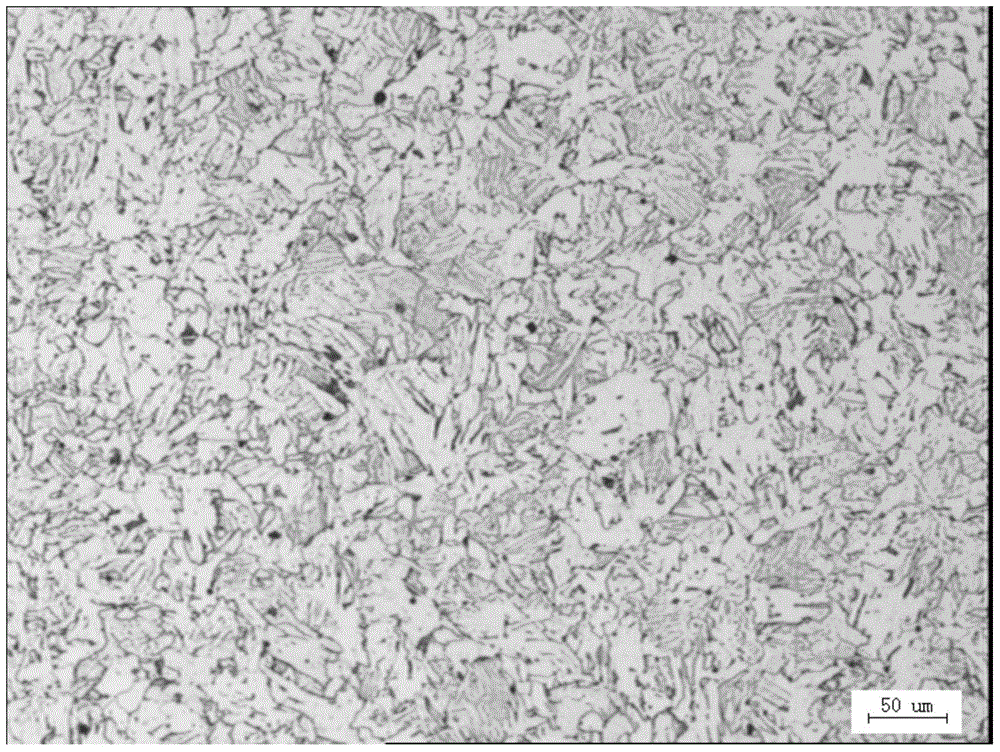

[0027] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

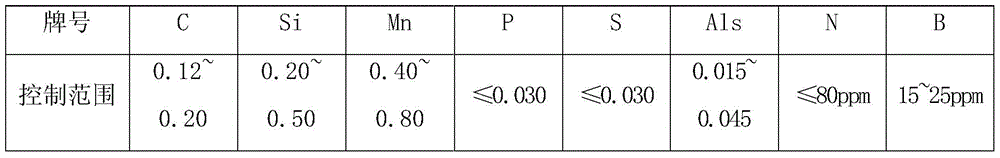

[0028] The chemical composition design, rolling process and cooling process used in this embodiment are applied to carbon structural steel and low alloy steel with a yield strength of 200-420 MPa in the current GB700, JIS G3101, JIS G3109 and other standard specifications, which can significantly improve the structure and Uniformity of properties, improved levels of toughness and ductility.

[0029] To this end, the main points of the plan are: first, the carbon content is less than 0.30%, and an ultra-low carbon design of less than 0.06% can be adopted, or a carbon content higher than 0.06% can be adopted without ultra-low carbon design, up to a maximum of 0.30%. Design, can still obtain a uniform microstructure, to avoid banded structure and tensile fracture, impact fracture delaminati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com