Distributed optical fiber temperature and stress sensing device

A stress sensing, optical fiber distribution technology, applied in thermometers, measuring devices, thermometers with physical/chemical changes, etc., can solve the problems of narrow spectral bandwidth, affecting detection results, low measurement temperature and strain accuracy, etc. flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

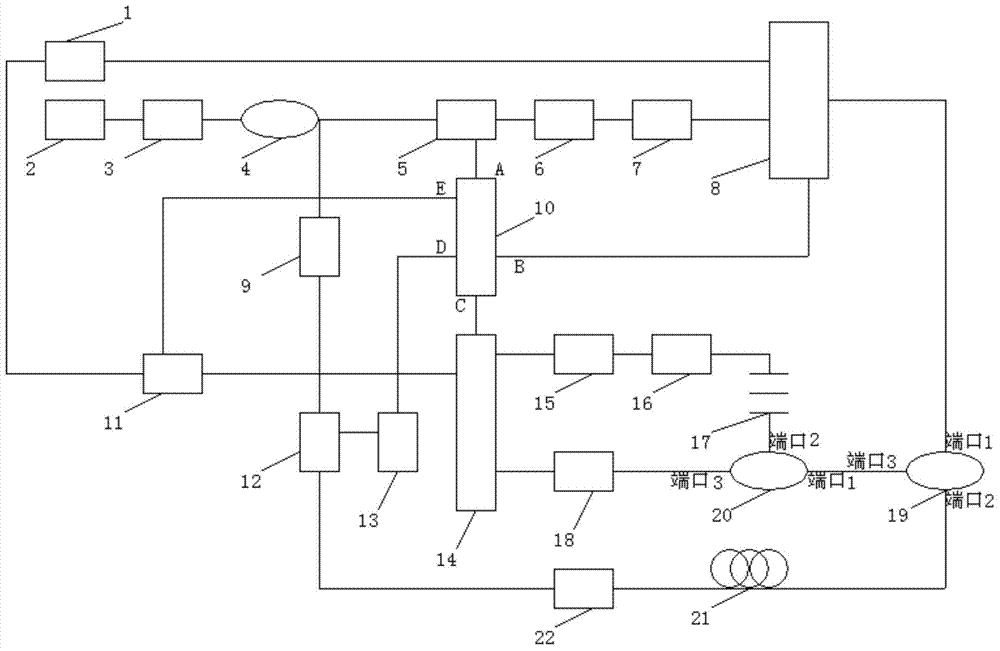

[0048] Such as figure 1 As shown, a distributed optical fiber temperature and stress sensing device includes a pulsed laser 1, a semiconductor laser 2, an optical isolator A3, an optical coupler 4, an acousto-optic modulator 5, a bait-doped fiber amplifier 6, and a polarizer 7 , Optical switch 8, polarization controller 9, signal generator 10, relay 11, electro-optic modulator 12, microwave source 13, data acquisition card 14, photodetector A15, B18, Raman filter 16, fiber Bragg grating 17, Circulator A19, B20, sensor fiber 21, optical isolator B22, characterized in that the output end of the pulse laser 1 is connected to one input end of the optical switch 8, and the other synchronous pulse output end of the pulse laser 1 is connected to the input end of the relay 11. Connected; the output end of the semiconductor laser 2 is connected to the input end of the optical isolator A3, the output end of the optical isolator A3 is connected to the input end of the 2×2 optical coupler...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line width | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com