Method and device for measuring refractive index and thickness of ice layer in ICF pellet

A measurement method and technology of refractive index, which is applied in the field of optical precision measurement, can solve the problems of ice layer thickness error and the inability to accurately measure the refractive index and thickness of the ice layer in the ICF target pellet at the same time, and achieve the effect of improving the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

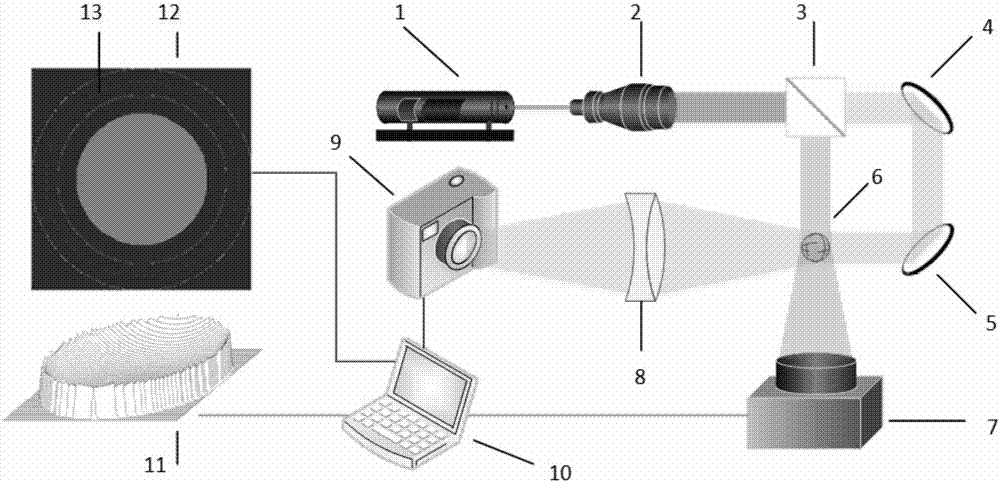

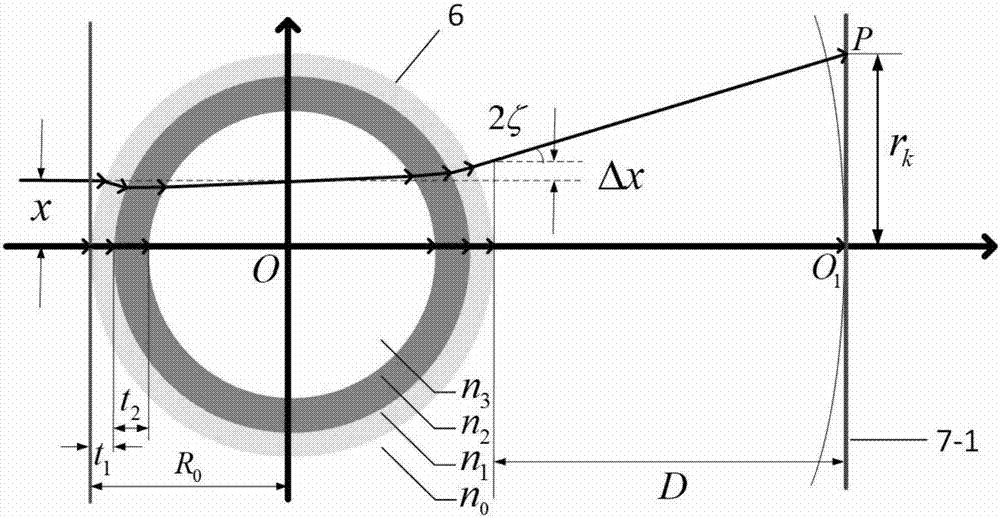

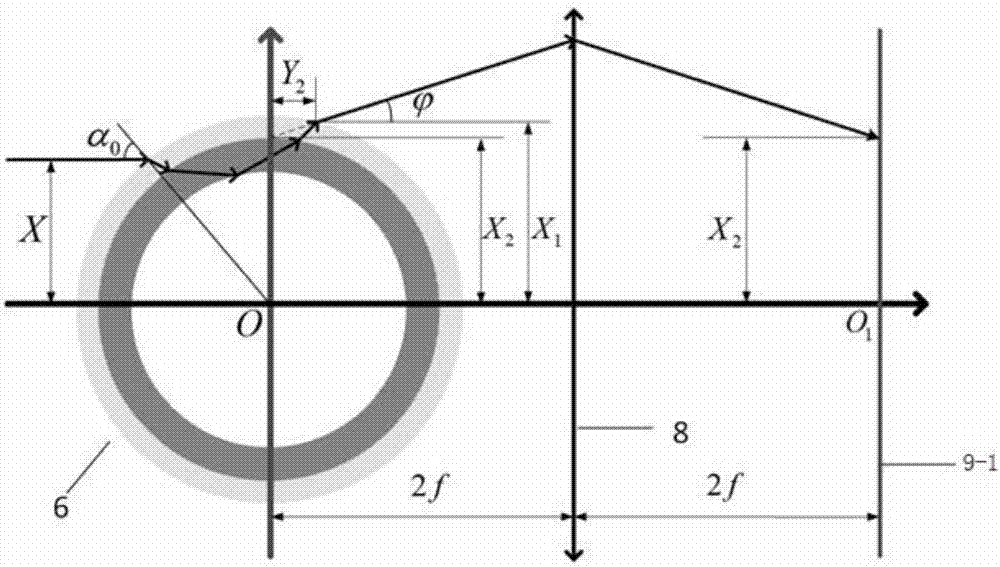

[0038] Such as figure 1 As shown, a measuring device for the refractive index and thickness of the ice layer in an ICF target pellet includes a light source 1, a beam expander 2, a beam splitter 3, a first reflector 4, a second reflector 5, and a target pellet 6 to be tested. , Wavefront sensor 7, lens 8, CCD image sensor 9, and computer 10. The light source 1, the beam expander 2, the beam splitter 3, and the first reflector 4 are placed in sequence along the same horizontal line. The light outlet of the light source 1 is aligned with the light inlet of the beam expander 2, and the light outlet of the beam expander 2 is The light entrance of the beam mirror 3 is aligned, and the light exit of the beam splitter 3 transmits light and the first reflector 4 is arranged at 45°. The target pellet 5 to be tested is placed on the side of the light exit of the beam splitter 3, and is on the same line as the light exit of the beam splitter 3; the second reflector 5 is horizontally align...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com