System capable of synchronously measuring transverse pressure and temperature of fiber grating based on polarization measurement

A technology of optical fiber grating and transverse pressure, which is applied in the measurement of the change force of the optical properties of the material when it is stressed, the measurement of heat, and the thermometer with physical/chemical changes, etc., which can solve the problems of long-term work stability and poor repeatability, Difficult long-term stable use, limited stability and other issues, to achieve the effect of good long-term temperature reliability, simple structure and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

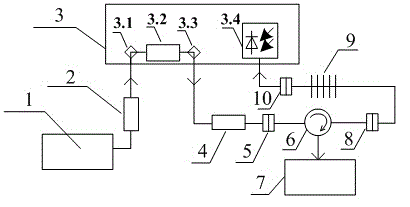

[0019] The light of the tunable laser 1 is input to the input APC interface 3.1 of the PDL tester 3 through the isolator 2, and then the polarization state of the laser is changed in a non-deterministic way through the built-in polarization controller 3.2 of the PDL tester 3 to make it Present all possible polarization states, and then output to the isolator 4 through another APC connector 3.3. The functions of the isolator 2 and the isolator 4 are to prevent the weak reflection of each node of the optical path in the sensing system from feeding back into the laser, causing The instability of the laser output leads to errors in the PDL measurement. Then the laser is input to the circulator 6 through the APC connector 5 coated with the refractive index matching paste, and an output port of the circulator 6 is connected to the APC connector 8 coated with the refractive index matching paste, and then connected to the FBG sensor 9, and the FBG sensor 9 Then input to the built-in p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com