Preparation method of large-area single-layer or multi-layer molybdenum diselenide single chip

A molybdenum diselenide, large-area technology, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve the problems of uneven MoSe2 morphology, inapplicability to large-scale production and application, and difficult control of thickness , to achieve the effect of high crystallinity, high repeatability and short synthesis cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] ⑴ Cleaning of silicon dioxide / silicon substrate:

[0036] ① Cut 1cm*2cm SiO2 with a glass knife 2 / Si substrate.

[0037] ② In a fume hood, firstly clean the substrate ultrasonically with acetone for 5 minutes, then ultrasonically clean it with absolute ethanol for 5 minutes, and finally rinse it with deionized water.

[0038] ③Then put the substrate into a mixture of concentrated sulfuric acid and hydrogen peroxide (3:1) and boil for 10 minutes.

[0039] ④ Rinse the substrate with deionization and dry it with nitrogen.

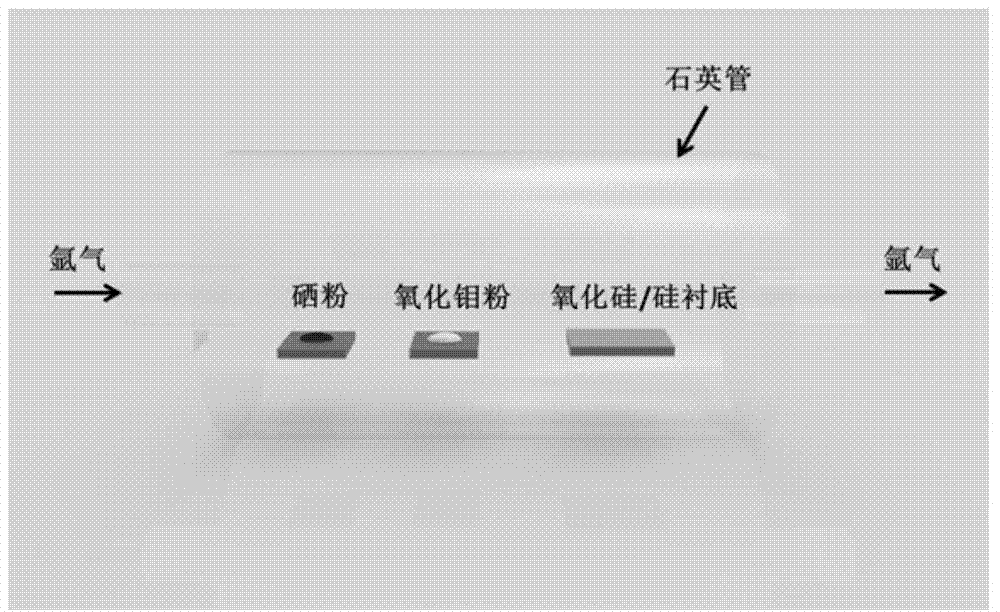

[0040] ⑵ SiO 2 The / Si substrate was placed 1 cm downstream from the center of the high temperature zone of the tube furnace. Weigh 20mg of MoO 3 The powder (not less than 99.90% purity) is placed in a ceramic boat, which is then placed in the center of the high temperature zone of the tube furnace. 0.8 g of Se powder was weighed into a ceramic boat, which was then placed 6 cm upstream of the high temperature zone of the tube furnace.

[0041] (...

Embodiment 2

[0045] ⑴ Cleaning of silicon dioxide / silicon substrate:

[0046] ① Cut 1cm*2cm SiO2 with a glass knife 2 / Si substrate.

[0047] ② In a fume hood, firstly clean the substrate ultrasonically with acetone for 5 minutes, then ultrasonically clean it with absolute ethanol for 5 minutes, and finally rinse it with deionized water.

[0048] ③ Then put the substrate into a mixture of concentrated sulfuric acid and hydrogen peroxide (3:1) and boil for 10 minutes.

[0049] ④ Rinse the substrate with deionization and dry it with nitrogen.

[0050] ⑵ SiO 2 The / Si substrate is placed 1 cm downstream of the center of the high temperature zone of the tube furnace. Weigh 10mg of MoO 3 The powder (not less than 99.90% purity) is placed in a ceramic boat, which is then placed in the center of the high temperature zone of the tube furnace. 0.5 g of Se powder was weighed into a ceramic boat, which was then placed 6 cm upstream of the high temperature zone of the tube furnace.

[0051] (3)...

Embodiment 3

[0055] ⑴ Cleaning of silicon dioxide / silicon substrate:

[0056] ① Cut 1cm*2cm SiO2 with a glass knife 2 / Si substrate.

[0057] ② In a fume hood, firstly clean the substrate ultrasonically with acetone for 5 minutes, then ultrasonically clean it with absolute ethanol for 5 minutes, and finally rinse it with deionized water.

[0058] ③Then put the substrate into a mixture of concentrated sulfuric acid and hydrogen peroxide (3:1) and boil for 10 minutes.

[0059] ④ Rinse the substrate with deionization and dry it with nitrogen.

[0060] ⑵ SiO 2 / Si substrate is placed downstream of the center of the high temperature zone of the tube furnace, 1cm away from the center of the high temperature zone, and 10mg of MoO is weighed 3 The powder (not less than 99.90% purity) is placed in a ceramic boat, which is then placed in the center of the high temperature zone of the tube furnace. Weigh 0.5g of Se powder and place it in a ceramic boat, and then place it at the upstream of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com