Preparation method of spherical zirconium diboride and silicon carbide aggregate powder

A technology of zirconium diboride and silicon carbide is applied in the field of preparation of zirconium diboride-silicon carbide (ZrB2-SiC) spherical agglomerate powder, which can solve the problem of difficulty in melting, easily broken powder, affecting coating performance, etc. To avoid the introduction of impurities, ensure the purity and quality, and eliminate the introduction of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

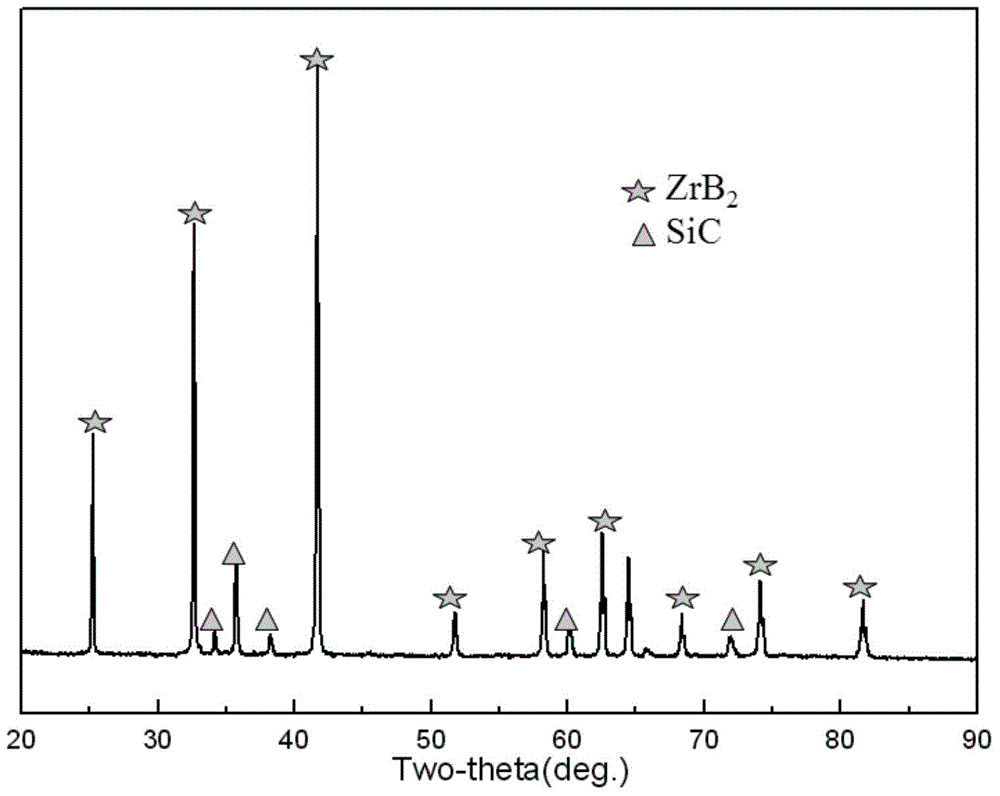

Image

Examples

Embodiment 1

[0029] (1) Mix 20g of zirconium diboride, 80g of silicon carbide and 100g of absolute ethanol into a suspension, put it into a ball mill tank for ball milling and mixing, the ball milling speed is 100r / min, and the ball milling time is 6h to obtain the precursor;

[0030] (2) Add 400g of absolute ethanol to the precursor obtained in step (1) for mixing, put it into a colloid mill for grinding and emulsification, and obtain a mixed suspension of mixed powder and absolute ethanol, wherein the colloid mill The speed is 2880r / min;

[0031] (3) Send the mixed suspension of the mixed powder and absolute ethanol obtained in step (2) into the induction plasma spray gun of the induction plasma spheroidization equipment through the liquid powder feeder, under the action of the atomizing gas argon , the suspension is atomized, and the atomized particles are spheroidized and densified after being heated by induction plasma. The working gas is a mixed gas of hydrogen and argon, the hydrog...

Embodiment 2

[0040] (1) Mix 20g of zirconium diboride, 40g of silicon carbide and 180g of absolute ethanol into a suspension, put it into a ball mill jar for ball milling and mixing, the ball milling speed is 400r / min, and the ball milling time is 2h to obtain the precursor;

[0041] (2) Add 300 g of absolute ethanol to the precursor obtained in step (1) and mix, put it into a colloid mill for grinding and emulsification, and obtain a mixed suspension of mixed powder and absolute ethanol, wherein the colloid mill The speed is 2880r / min;

[0042](3) Send the mixed suspension of the mixed powder and absolute ethanol obtained in step (2) into the induction plasma spray gun of the induction plasma spheroidization equipment through the liquid powder feeder, under the action of the atomizing gas argon , the suspension is atomized, and the atomized particles are spheroidized and densified after being heated by induction plasma. The working gas is a mixed gas of hydrogen and argon, the flow of hy...

Embodiment 3

[0051] (1) Mix 20g of zirconium diboride, 50g of silicon carbide and 200g of absolute ethanol into a suspension, put it into a ball mill tank for ball milling and mixing, the ball milling speed is 300r / min, and the ball milling time is 3h to obtain the precursor;

[0052] (2) Add 250 g of absolute ethanol to the precursor obtained in step (1) and mix, put it into a colloid mill for grinding and emulsification, and obtain a mixed suspension of mixed powder and absolute ethanol, wherein the colloid mill The speed is 2880r / min;

[0053] (3) Send the mixed suspension of the mixed powder and absolute ethanol obtained in step (2) into the induction plasma spray gun of the induction plasma spheroidization equipment through the liquid powder feeder, under the action of the atomizing gas argon , the suspension is atomized, and the atomized particles are spheroidized and densified after being heated by induction plasma. The working gas is a mixed gas of hydrogen and argon, the hydrogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com