Metal continuous casting process and metal continuous casting device based on electromagnetic excitation combined with mechanical stirring

A technology of mechanical stirring and electromagnetic excitation, applied in the field of metal continuous casting process and metal continuous casting device, can solve the problems of shielding effect energy loss, complex process, weakening, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

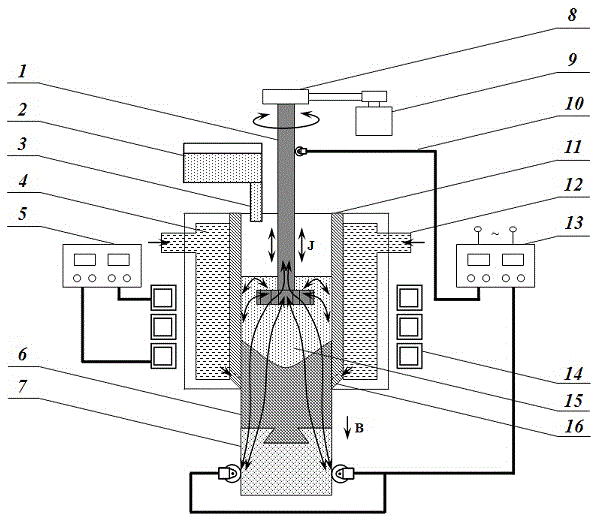

[0035] In this example, see figure 1 and figure 2 , a metal continuous casting device implementing the metal continuous casting process of electromagnetic excitation combined mechanical stirring, comprising a tundish 2, a nozzle 3, a crystallizer water cooling jacket 4, a water-cooled mold crystallizer 11 and a dummy rod 7, inside the tundish 2 The molten metal 15 passes through the nozzle 3 and is poured into the water-cooled mold crystallizer 11 at a set speed, and then through continuous casting, the billet 6 is pulled out by the dummy bar 7, and a crystallizer is provided close to the outside of the water-cooled mold mold 11 Water cooling jacket 4, cooling water flows out from water outlet 16 after water inlet 12 passes through crystallizer water cooling jacket 4, water cooling mold crystallizer 11 is placed in coil 14, the current output end of magnetic field generator 5 is connected with coil 14, open The magnetic field generator 5 adjusts the intensity of the DC curre...

Embodiment 2

[0040] This embodiment is basically the same as Embodiment 1, especially in that:

[0041] In this embodiment, the material of the rotor stirring paddle 1 is the same metal as the molten metal 15 cooled by inert gas, and the rotor stirring paddle 1 made of the same metal as the molten metal 15 will not give the molten metal 15 Any secondary pollution is caused, especially suitable for continuous casting to manufacture high-purity metal material billet 6, and it has obvious advantages in continuous casting of pure steel.

Embodiment 3

[0043] This embodiment is basically the same as the previous embodiment, and the special features are:

[0044] In this embodiment, the number of rotor stirring paddles 1 is 2, which is better than the stirring effect of 1 rotor stirring paddle 1, which can improve the turbulent agitation effect of forming chaotic flow inside the metal melt 15, and further improve the crystal structure of solidified structure. Grain refinement and uniformity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com