Phenylethanolamine A molecularly imprinted membrane, preparation method thereof and applications thereof

A molecularly imprinted membrane and phenylethanolamine technology, applied in chemical instruments and methods, membrane technology, ion exchange, etc., can solve the problems of poor selectivity and large sample matrix interference, and achieve the effect of regular shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

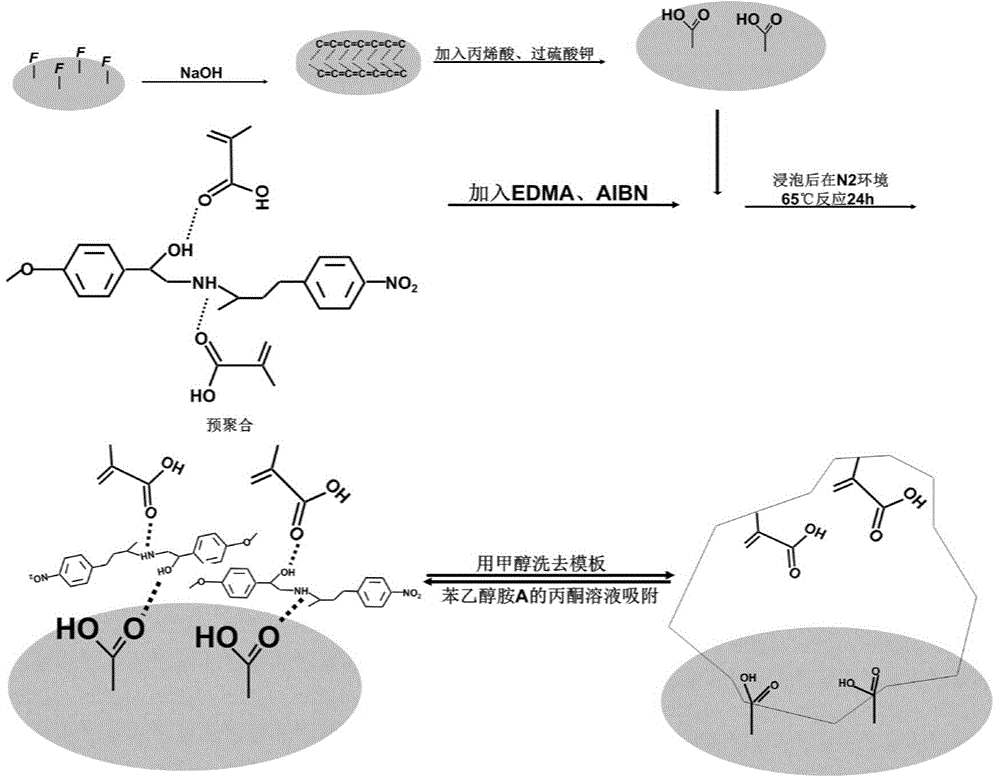

[0032] Embodiment 1, preparation of phenylethanolamine A molecularly imprinted membrane

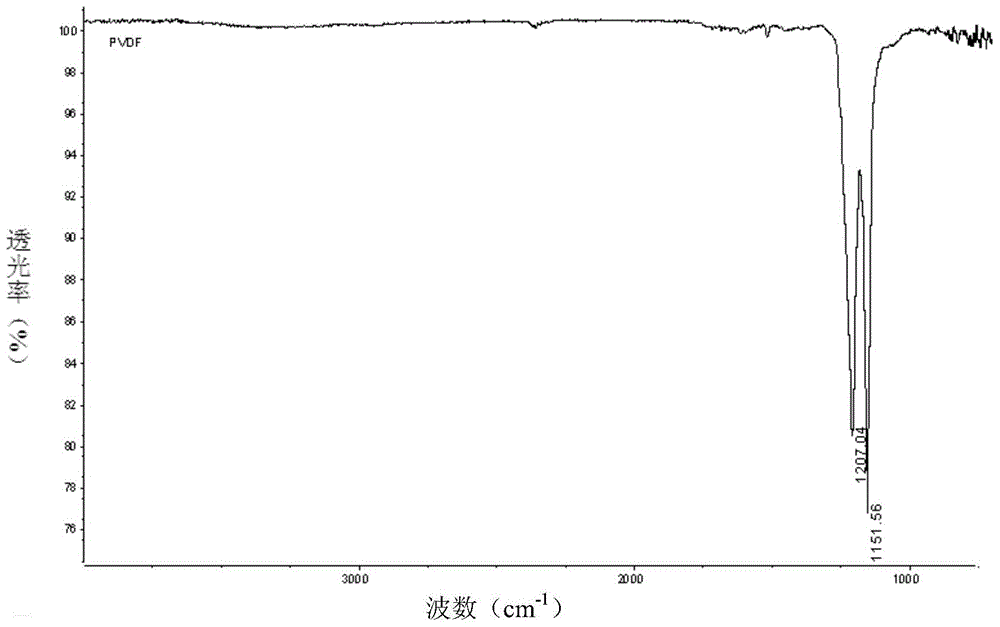

[0033] (1) Surface modification and activation of PVDF membrane

[0034] Surface modification of PVDF membrane: immerse PVDF membrane in 3wt% NaOH aqueous solution at 60°C for 12 hours, absorb excess aqueous solution on the surface, then immerse in 10wt% acrylic acid and 1wt% initiator potassium persulfate in aqueous solution, and pass through nitrogen After deoxygenation, react at a constant temperature of 70°C for 5h.

[0035] Activation of the surface-modified PVDF membrane: first soak the treated PVDF membrane in ultrapure water for 1 hour, take it out and immerse it in acetonitrile for 0.5 hours, then soak it in 0.15mol / L fresh AIBN acetonitrile solution for 20 minutes, take it out and evaporate it Dry acetonitrile was immediately immersed in the molecular imprinting mix solution in the following steps.

[0036] (2) Preparation of phenylethanolamine A molecularly imprinted membrane...

Embodiment 2

[0038] Example 2, Optimization of the preparation method of phenylethanolamine A molecularly imprinted membrane

[0039] The phenylethanolamine A molecularly imprinted membrane was prepared according to the steps in Example 1, wherein the ratio of the template molecule phenylethanolamine A, the monomer MAA, the cross-linking agent EGDMA and the initiator AIBN is shown in Table 1.

[0040] The concentration of the standard phenylethanolamine A acetonitrile solution used in the adsorption test was 5mg / L, 250ml was adsorbed, and 1ml was eluted. Each data was measured in parallel three times, and the RSD was less than or equal to 5.5%. Through the comparison of the adsorption amount of phenylethanolamine A between different ratios and imprinted and non-imprinted materials, the mass ratio between the three finally selected was 1:6:30.

[0041] Table 1 Selection of molecularly imprinted membrane synthesis ratio

[0042]

Embodiment 3

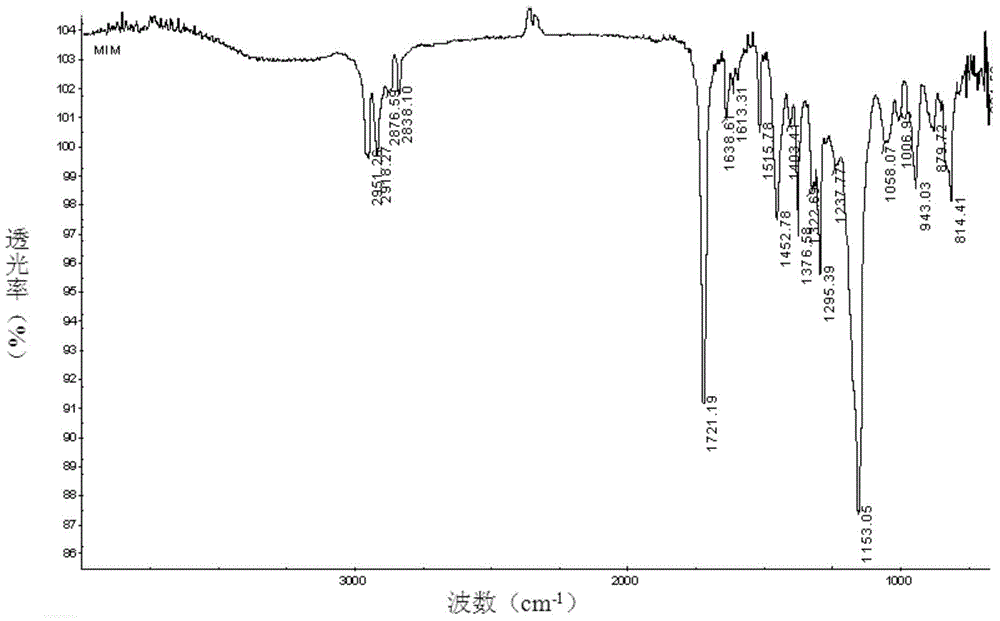

[0043] The characterization of the phenylethanolamine A molecularly imprinted membrane prepared in embodiment 3 and embodiment 1

[0044] (1) Thermogravimetric analysis

[0045] In order to determine the modification effect on the surface of PVDF membrane, the modified (surface modification and activated PVDF membrane prepared in Example 1) and unmodified PVDF membrane were characterized by thermogravimetric analysis, the results are as follows figure 2 shown. From figure 2 It can be seen that the relationship between the percentage of mass retention and temperature is obtained through thermogravimetric experiments. The grafted PVDF membrane begins to lose weight before the ungrafted PVDF membrane, and the weight loss temperature of the grafted PVDF membrane is lower than that of the ungrafted PVDF membrane. PVDF membrane. Due to the characteristics of heat resistance and good stability of PVDF membrane, the weight loss temperature of ungrafted PVDF membrane is higher tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com