HA (hydroxylapatite) micro-nano whisker reinforced calcium phosphate ceramic material and preparation method and application thereof

A technology of calcium phosphate ceramics and ceramic materials, applied in the field of biomedical materials, can solve problems such as reducing the biological activity of materials, and achieve the effects of ensuring osteoinductive ability, enhancing bone connection and healing functions, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

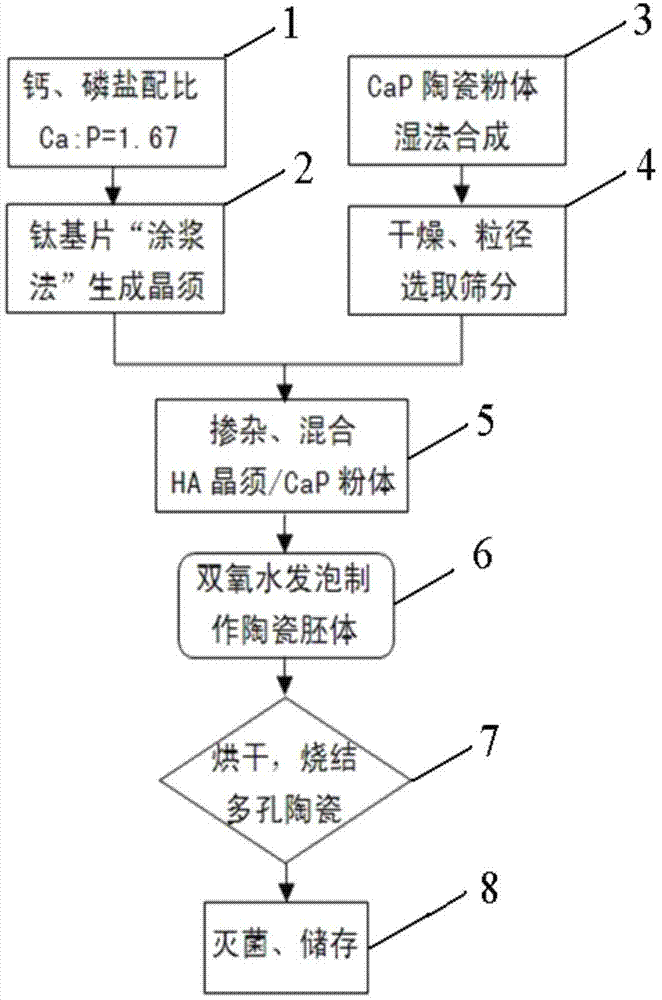

Method used

Image

Examples

Embodiment 1

[0056] 1) Synthesize the matrix phase β-phase tricalcium phosphate (β-TCP) powder by "wet chemical reaction", dry it and crush it by airflow, and screen the dry powder with a diameter of 80-160 μm as the precursor powder for the preparation of porous ceramic embryo body material;

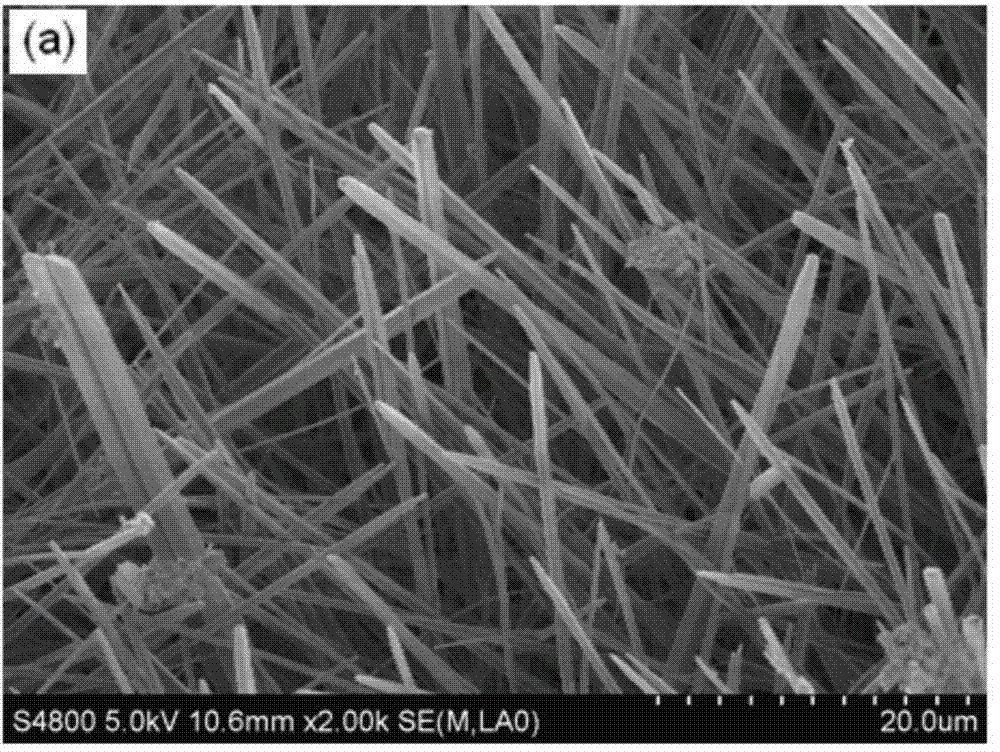

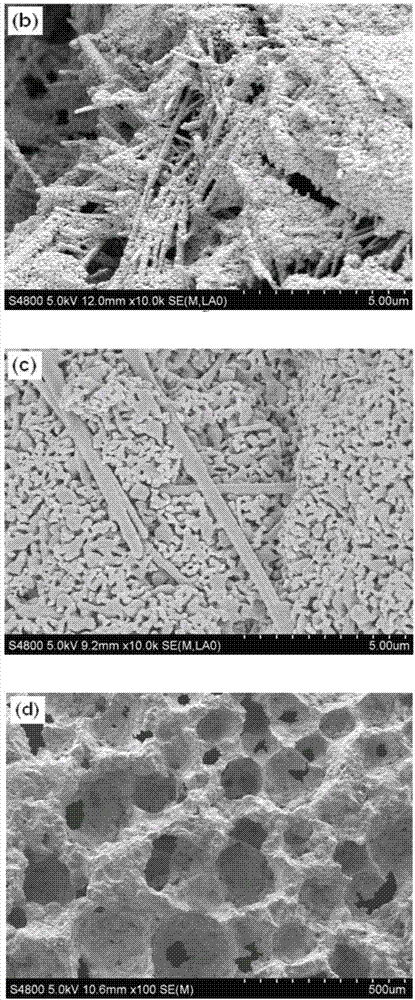

[0057] 2) The reinforcement phase HA micro-nano whiskers were synthesized by the "slurry method", and the Ca(NO 3 ) 2 4H 2 O and (NH 4 ) 2 HPO 4 Dissolve in deionized water to make a paste; weigh KNO at a molar ratio of 1:1:1 3 、LiNO 3 , KOH and deionized water are mixed and stirred to form a paste as a cosolvent, and then the two paste-like slurries are fully mixed, adjusted to pH=6.5 with hydrochloric acid, coated on the surface of a clean titanium sheet, and placed in a polytetrafluoroethylene In a hydrothermal reaction kettle with ethylene as the substrate, the temperature was raised to 350°C at a rate of 5°C / min, reacted for 10 hours, and naturally cooled to room temperature. The reactio...

Embodiment 2

[0062] Porous calcium phosphate bioactive ceramic products were prepared with biphasic calcium phosphate powder (HA / TCP) as the ceramic matrix phase composition of 95%, and HA micro-nano whiskers with a mass percentage of 5% as the reinforcing phase. The product preparation process and steps are the same as those in Example 1, except that in Step 1, the ceramic powder is synthesized as a dual-phase calcium phosphate material through a "wet chemical reaction". The maximum compressive strength of the ceramic material after the obtained HA micro-nano whiskers are reinforced is 3.35MPa, which is 1.86 times higher than the pure dual-phase calcium phosphate ceramic material 1.80MPa not doped with HA micro-nano whiskers. The maximum compressive strength of porous ceramics is 1.08 MPa higher, because the matrix phase of the biphasic calcium phosphate material with better mechanical properties contributes additional mechanical strength.

Embodiment 3

[0064] Porous calcium phosphate bioactive ceramic products were prepared with pure hydroxyapatite powder (HA) as the ceramic matrix phase composition of 95%, and HA micro-nano whiskers with a mass percentage of 5% as the reinforcing phase. The product preparation process and steps are the same as in Example 1, except that in Step 1, the ceramic powder is synthesized as hydroxyapatite by "wet chemical reaction". The maximum compressive strength of the ceramic material after the obtained HA micro-nano whiskers are reinforced is 4.31MPa, which is 1.96 times higher than the pure dual-phase calcium phosphate ceramic material not doped with HA micro-nano whiskers, and is higher than the reinforced porous ceramics in Example 1. The maximum compressive strength is 2.04MPa higher. This is because in calcium phosphate ceramics, under the same pore structure and the same sintering process conditions, the strength order of different calcium phosphate ceramic materials is: HA>BCP>TCP.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com