Semiconductor power device

A technology for power devices and semiconductors, applied in the field of semiconductor power devices, can solve the problems of low turn-on speed and turn-off speed, inability to take into account the switching speed, etc., to reduce on-resistance and turn-on power loss, improve performance, and eliminate negative resistance. zone effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

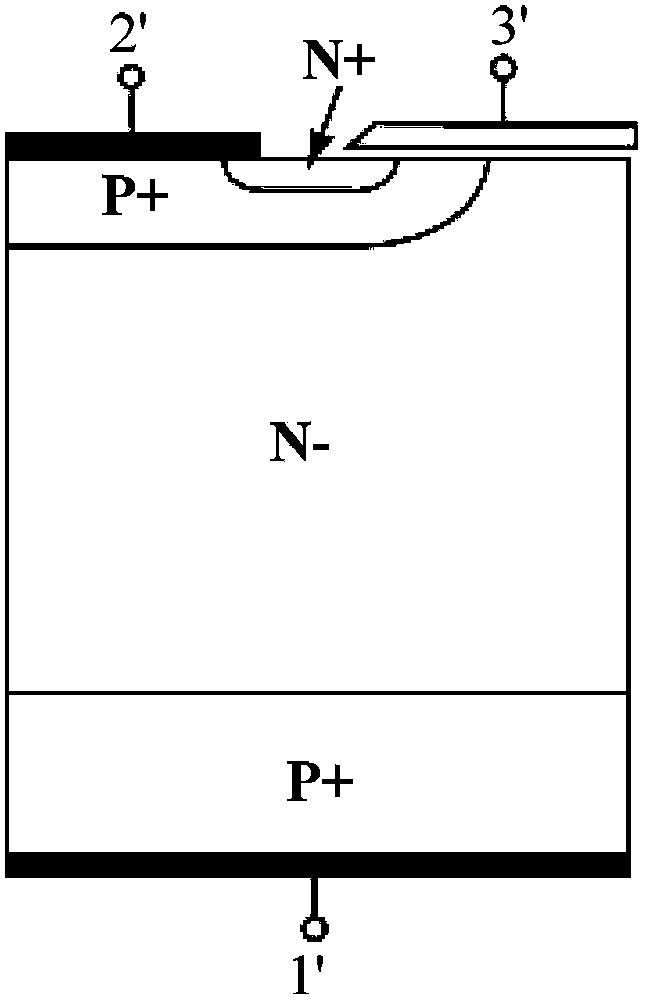

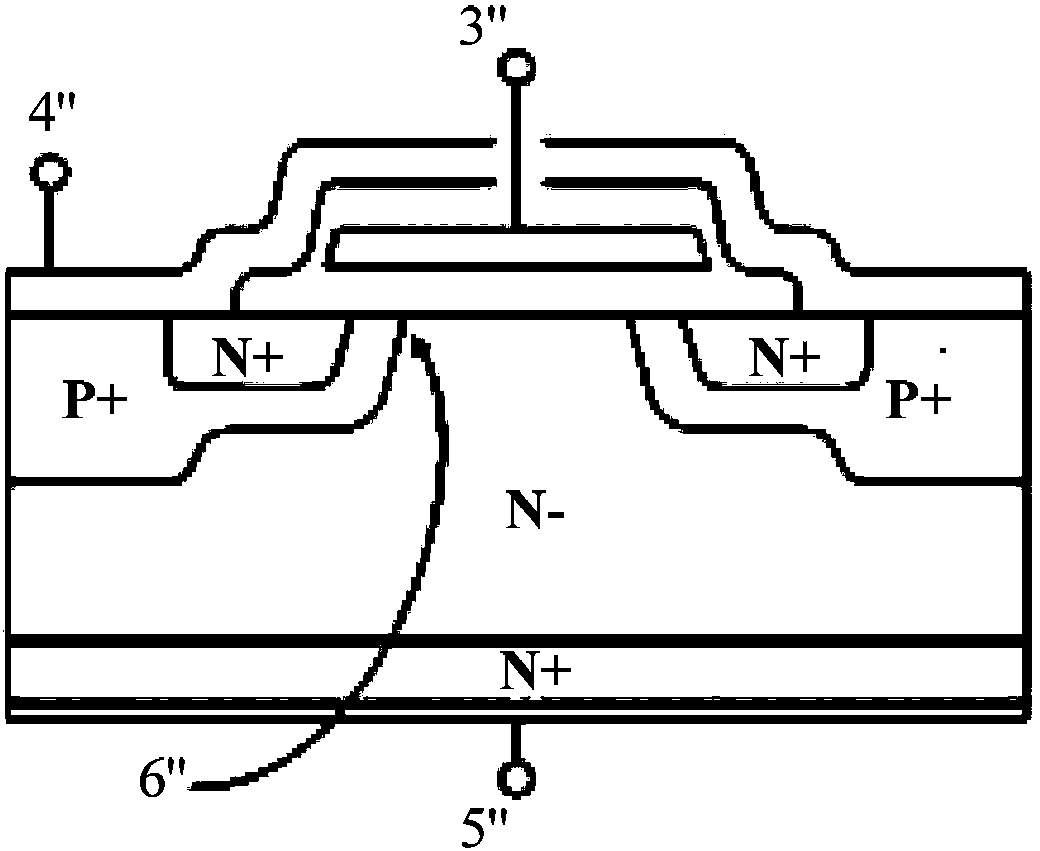

[0063] Such as Figure 4 As shown, the present invention provides a semiconductor power device, which at least includes: a drain 101, a drain region 20, a drift region 30, a body region 40, a source region 50, a gate region 60, a heavily doped second conductivity type region 70 , isolation structure 80 , source / emitter 90 , collector 102 , termination structure 110 .

[0064] It should be pointed out that in the first embodiment, the first conductivity type is N-type, and the second conductivity type is P-type, but they are not limited thereto. In other embodiments, the first conductivity type can be P-type , then the second conductivity type is N-type; the material of the drain region 20, the drift region 30, the body region 40, the source region 50, the heavily doped second conductivity type region 70, and the terminal structure 110 is silicon material, but Not limited thereto, in other embodiments, the material of each of the regions may also be silicon carbide or gallium ...

Embodiment 2

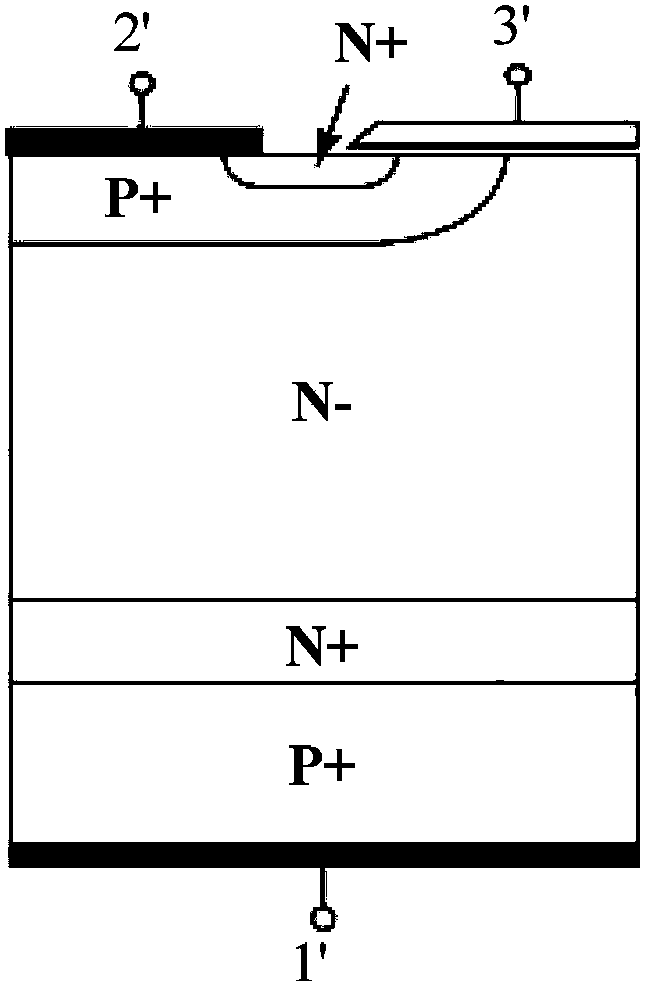

[0090] The second embodiment adopts basically the same technical solution as the first embodiment, except that the drift region 30 in the first embodiment is divided into the first drift region 301 and formed in the first drift region 301 in the second embodiment. The second drift region 302 above the region.

[0091] Such as Figure 7 As shown, the present invention provides a semiconductor power device, which at least includes: a drain 101, a drain region 20, a first drift region 301, a second drift region 302, a body region 40, a source region 50, a gate region 60, The second conductivity type region 70 , the isolation structure 80 , the source / emitter 90 , the collector 102 , and the terminal structure 110 are heavily doped. In the following, only the parts different from those in the first embodiment will be described in detail, and the parts that are the same as those in the first embodiment will not be repeated one by one.

[0092] In the second embodiment, the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com