Composite porous fibers with core-shell structures and preparation method of dual-pore structure membrane

A composite fiber and porous fiber technology applied in the field of bioengineering to achieve high electrical conductivity, simple steps, and good practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

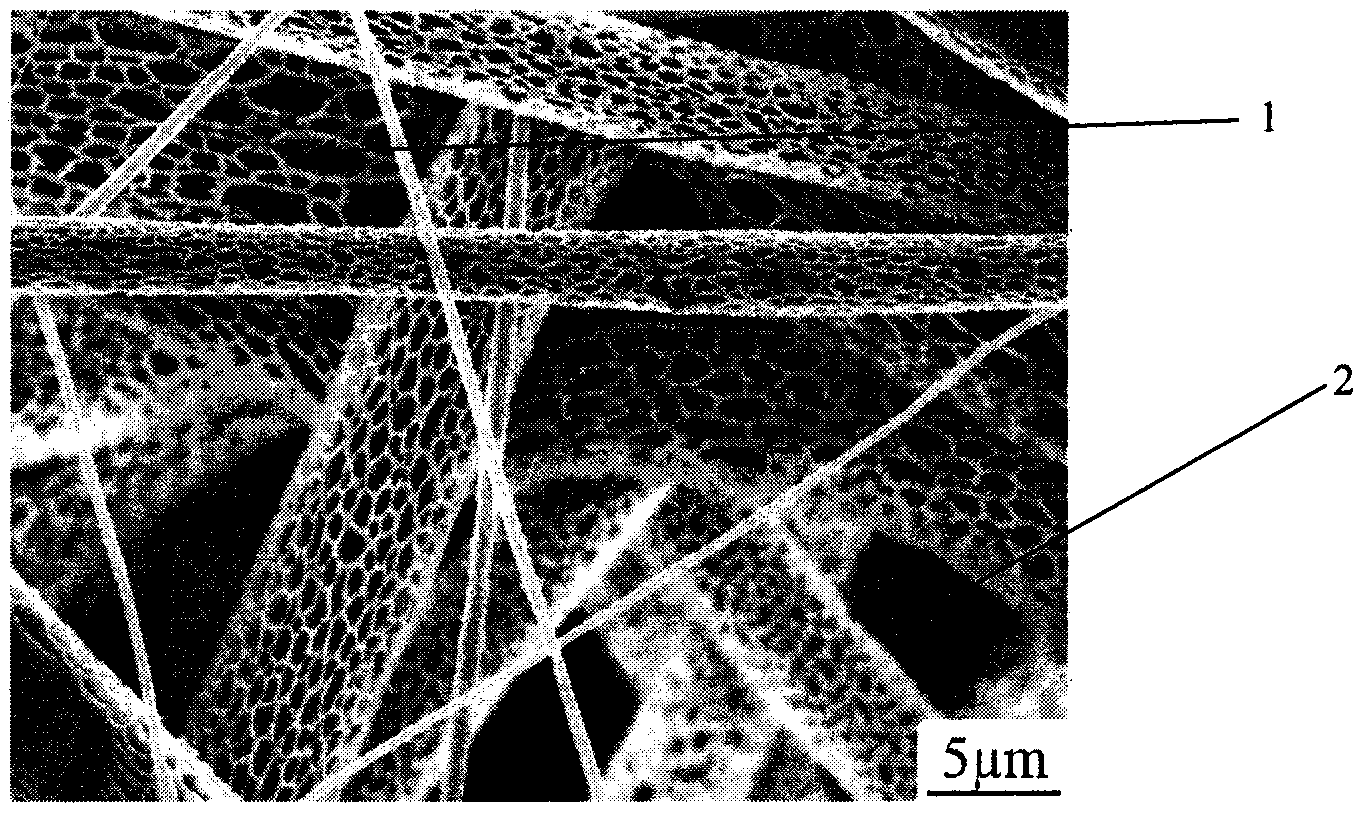

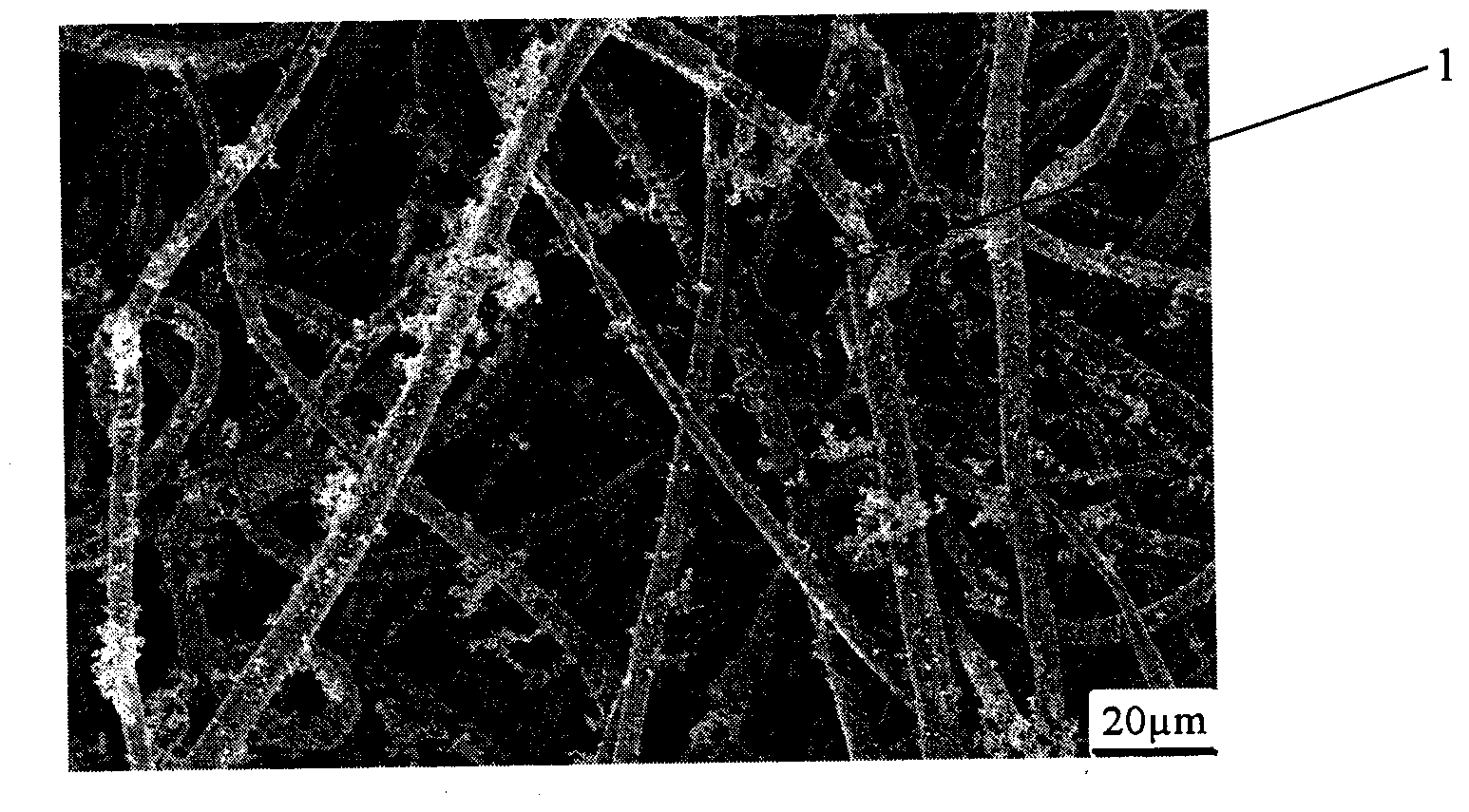

[0045] Preparation of polylactic acid / polyaniline composite micro / nanofiber dual-porous membrane with polyaniline as the shell and polylactic acid as the core, which is interwoven with composite porous fibers with a core-shell structure

[0046] Step 1 Preparation of polylactic acid spinning dope

[0047] First weigh a certain amount of dichloromethane and place it in a stoppered Erlenmeyer flask, then add a certain amount of PLLA slices into it, stir magnetically at room temperature for 5 hours, and prepare a spinning solution with a mass fraction of 12%.

[0048] Step 2 Preparation of polylactic acid hollow porous fibers and double-porous membranes by electrospinning

[0049] Pour the prepared solution into the solution reservoir (20mL syringe), use the flattened injection needle as the capillary for jetting fine flow, connect the positive pole of the high-voltage power supply, connect the receiver to the negative pole, and the amount of solution extruded is controlled by th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Long axis | aaaaa | aaaaa |

| Short axis | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com