Water-based fluorine-containing epoxy paint

An epoxy coating and water-based epoxy resin technology, applied in the coating field, can solve the problems of epoxy coating weather resistance, poor wear resistance, lack of waterproof and anti-icing performance, and high surface energy of the coating film, and achieves low cost and production. and the coating process are both environmentally friendly and the production process is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

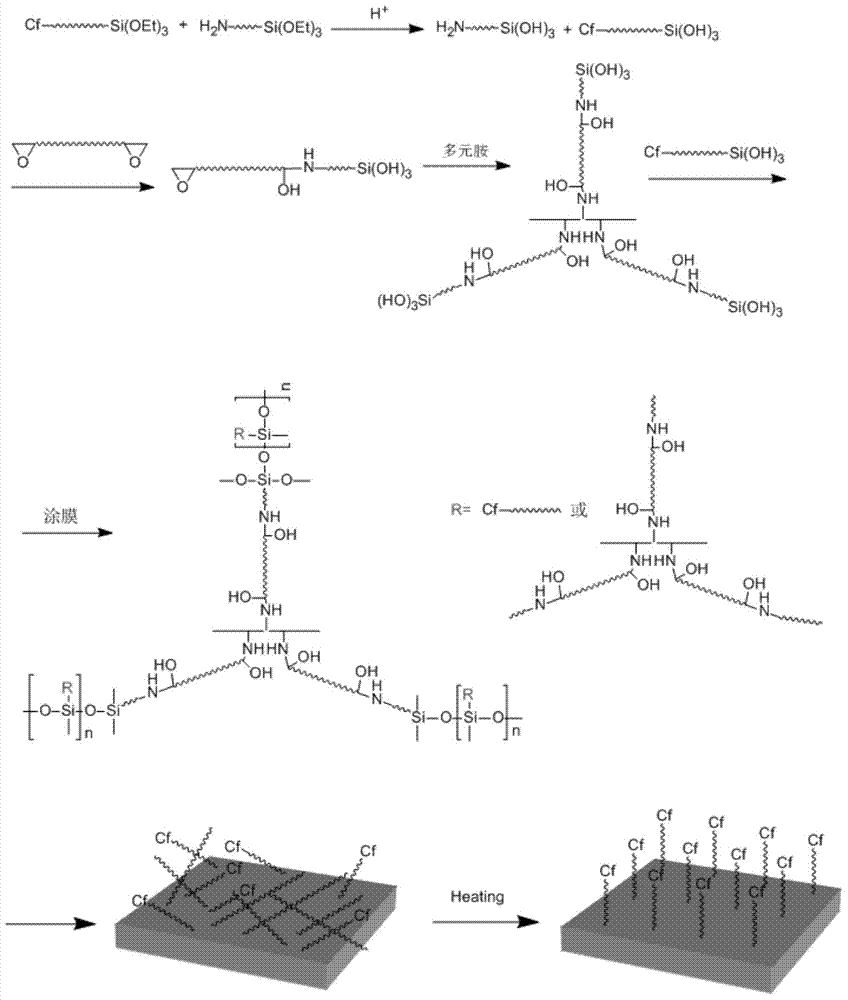

Method used

Image

Examples

Embodiment 1

[0023] (1) Add 20 parts by volume of absolute ethanol, 0.5 parts by volume of γ-aminopropyltriethoxysilane (KH-550), and 0.2 parts by volume of heptadecylfluorodecyltriethoxysilane (FAS) in Mix evenly under magnetic stirring, slowly adjust the pH value to about 4 with 50% hydrochloric acid, and obtain fluorine-containing silicone sol after reacting at room temperature for 45 minutes.

[0024] (2) At room temperature, mix 4 parts by volume of the above-mentioned sol with 10 parts by volume of water-based epoxy resin emulsion (Zhejiang Anbang New Material Co., Ltd., AB-EP-51, solid content 49-51%), under magnetic stirring, React at room temperature for 0.5h. After the reaction, the amine-containing silanol is grafted onto the epoxy to obtain a modified water-based epoxy emulsion.

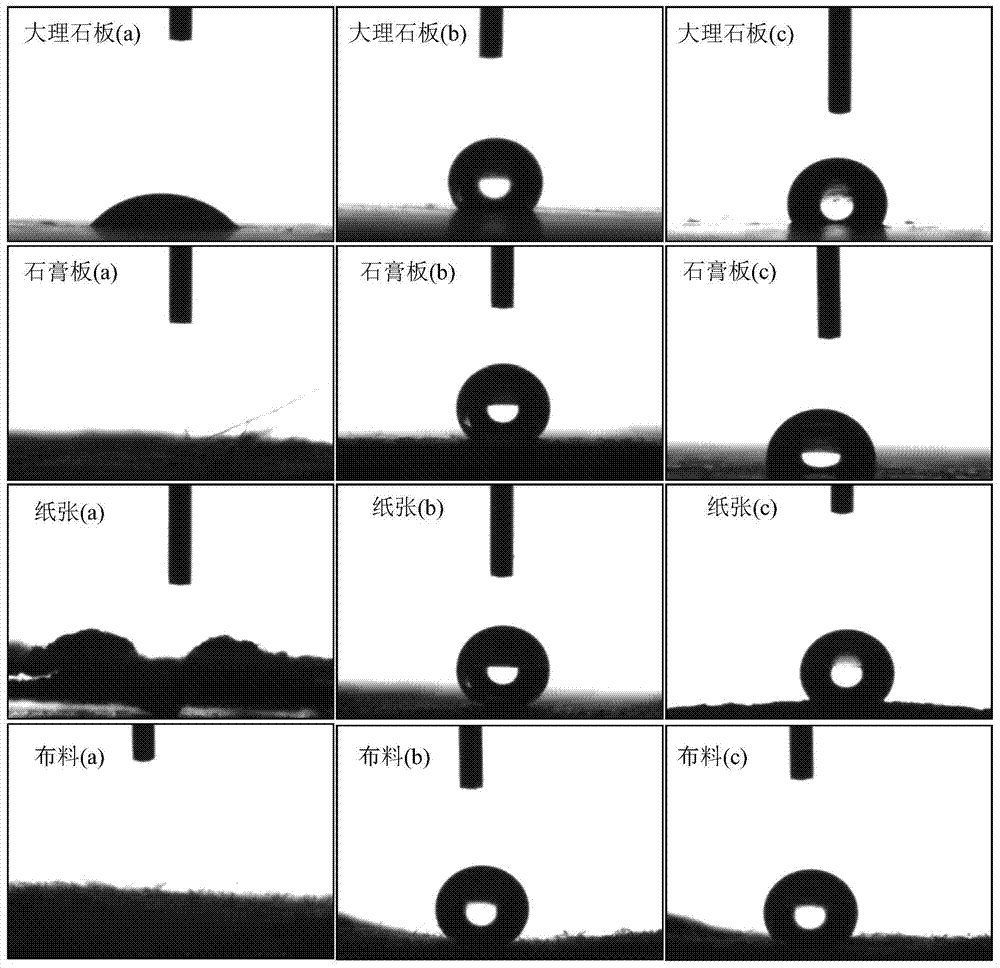

[0025] (3) At room temperature, take 1.5 parts of modified amine curing agent (Zhejiang Anbang New Material Co., Ltd., AB-HGF, solid content 39-41%) into the above modified epoxy emulsion, and react u...

Embodiment 2

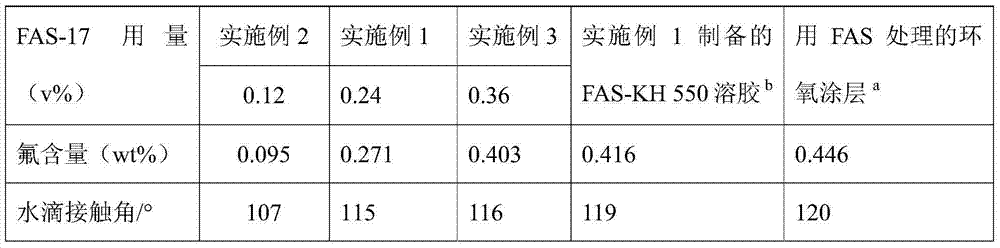

[0032] The amount (v%) of heptadecafluorodecyltriethoxysilane (FAS) was changed to 0.12v%, and the other conditions were the same as in Example 1 to prepare a water-based fluorine-containing epoxy resin coating.

[0033] After the prepared water-based fluorine-containing epoxy resin coating was dip-coated on the glass surface, it was cured at 120°C for 1 hour to obtain a surface coating. The surface fluorine content of the coating was analyzed by X-ray fluorescence spectroscopy, and the results are shown in the table 2.

Embodiment 3

[0035] The amount (v%) of heptadecafluorodecyltriethoxysilane (FAS) was changed to 0.36v%, and other conditions were the same as in Example 1 to prepare a water-based fluorine-containing epoxy resin coating.

[0036] After the prepared water-based fluorine-containing epoxy resin coating was dip-coated on the glass surface, it was cured at 120°C for 1 hour to obtain a surface coating. The surface fluorine content of the coating was analyzed by X-ray fluorescence spectroscopy, and the results are shown in the table 2.

[0037] Table 2 Fluorine content and contact angle on coating surface

[0038]

[0039] a: The preparation method of the epoxy coating treated with FAS is: first treat the glass surface with the water-based epoxy resin emulsion in Example 1 to obtain an epoxy coating, and then immerse the epoxy coating in heptadecafluorodecyl tri Ethoxysilane (FAS) n-hexane solution (FAS volume fraction 0.5%) was treated for 1 h, and then baked at 120 ° C for 1 h to obtain an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water droplet contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com