Method for producing high-purity potassium chloride solution for preparation of potassium carbonate and co-producing low sodium salt

A potassium chloride solution, potassium chloride technology, applied in the direction of alkali metal chloride, alkali metal halide purification, etc., can solve the problem of uneconomical production cost, uneven mixing of solid and solid phase, affecting product quality and uniform stability And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

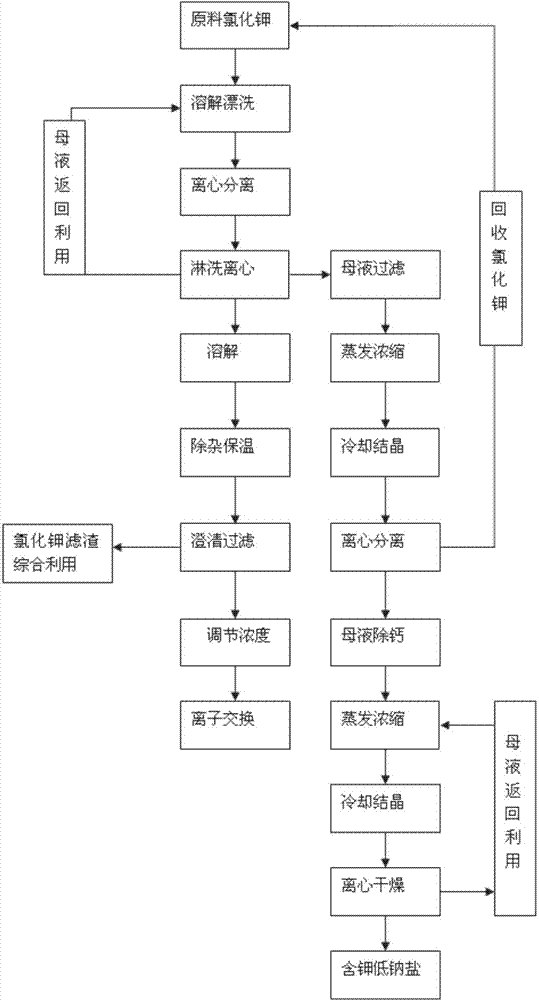

[0074] Embodiment 1, a kind of method for producing high-purity potassium chloride solution and co-production of low-sodium salt required for the preparation of potassium carbonate, using agricultural grade potassium chloride (potassium chloride with a purity of 95.1%) as raw material, the following steps are carried out successively :

[0075] 1), Potassium chloride dissolved rinse:

[0076] Put 3000Kg of agricultural grade potassium chloride with a content (purity) of 95.1% into 2400L of washing liquid, stir and rinse at room temperature for 60min at a speed of 600 rpm.

[0077] The washing solution is a saturated solution of potassium chloride with a purity of ≥90% or the potassium chloride rinsing solution obtained in the following step 2) (recycled and reused).

[0078] Remarks: Initially, use the above-mentioned saturated solution of potassium chloride with a purity ≥ 90%; then, use the potassium chloride rinse solution obtained by centrifugation in the following step 2...

Embodiment 2

[0116] Embodiment 2, a kind of method for producing high-purity potassium chloride solution and co-production low-sodium salt required for the preparation of potassium carbonate, using agricultural grade potassium chloride (potassium chloride with a purity of 95.1%) as raw material, the following steps are carried out successively :

[0117] Step 1) to step 3) are the same as in Example 1.

[0118] 4), impurity removal, heat preservation and precipitation, clear liquid filtration:

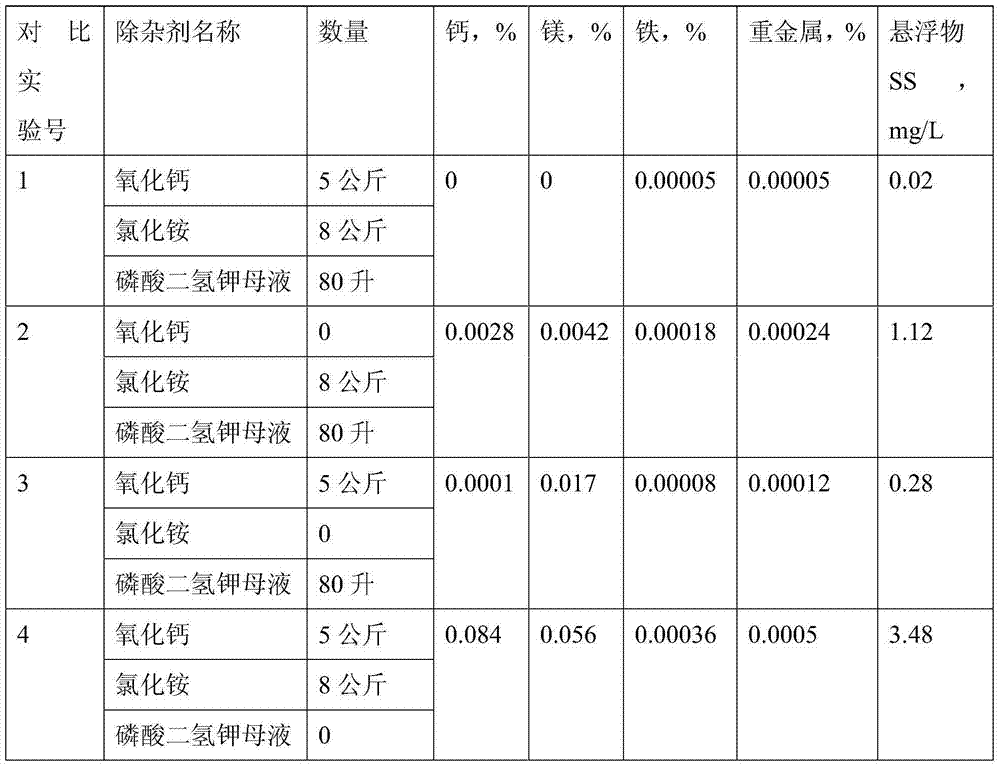

[0119] Add 5Kg calcium oxide to potassium chloride solution I, stir for 10 minutes, then add 80L potassium dihydrogen phosphate mother liquor (concentration: 300g / L) and 8Kg ammonium chloride, stir for 10 minutes, then add potassium hydroxide to adjust the pH of the solution, control Solution pH=12±0.2, finally add 100Kg sawdust, stir for 30 minutes; keep warm and naturally sink for 2 hours at around 45-50°C;

[0120] The rest are the same as step 4 of embodiment 1).

[0121] The dried potassium...

Embodiment 3

[0126] Embodiment 3, a kind of method for producing high-purity potassium chloride solution and co-production low-sodium salt required for the preparation of potassium carbonate, using agricultural grade potassium chloride (potassium chloride with a purity of 95.1%) as raw material, the following steps are carried out successively :

[0127] Step 1) to step 3) are the same as in Example 1.

[0128] 4), impurity removal, heat preservation and precipitation, clear liquid filtration:

[0129] Add 5Kg calcium oxide to potassium chloride solution I, stir for 10 minutes, then add 120L potassium dihydrogen phosphate mother liquor (concentration: 300g / L) and 12Kg ammonium chloride, stir for 10 minutes, then add potassium hydroxide to adjust the pH of the solution, control Solution pH=12±0.2, finally add 100Kg sawdust, stir for 30 minutes; keep warm and naturally settle for 2 hours at around 45-50°C.

[0130] The rest are the same as step 4 of embodiment 1).

[0131] The dried potas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com