Test device and test method for testing delivery capacity of steam security valve

A test device and safety valve technology, which can be used in measurement devices, testing of mechanical parts, testing of machine/structural parts, etc., can solve the problems of reducing the volume of the accumulator, reduce the volume, reduce the construction cost, test high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

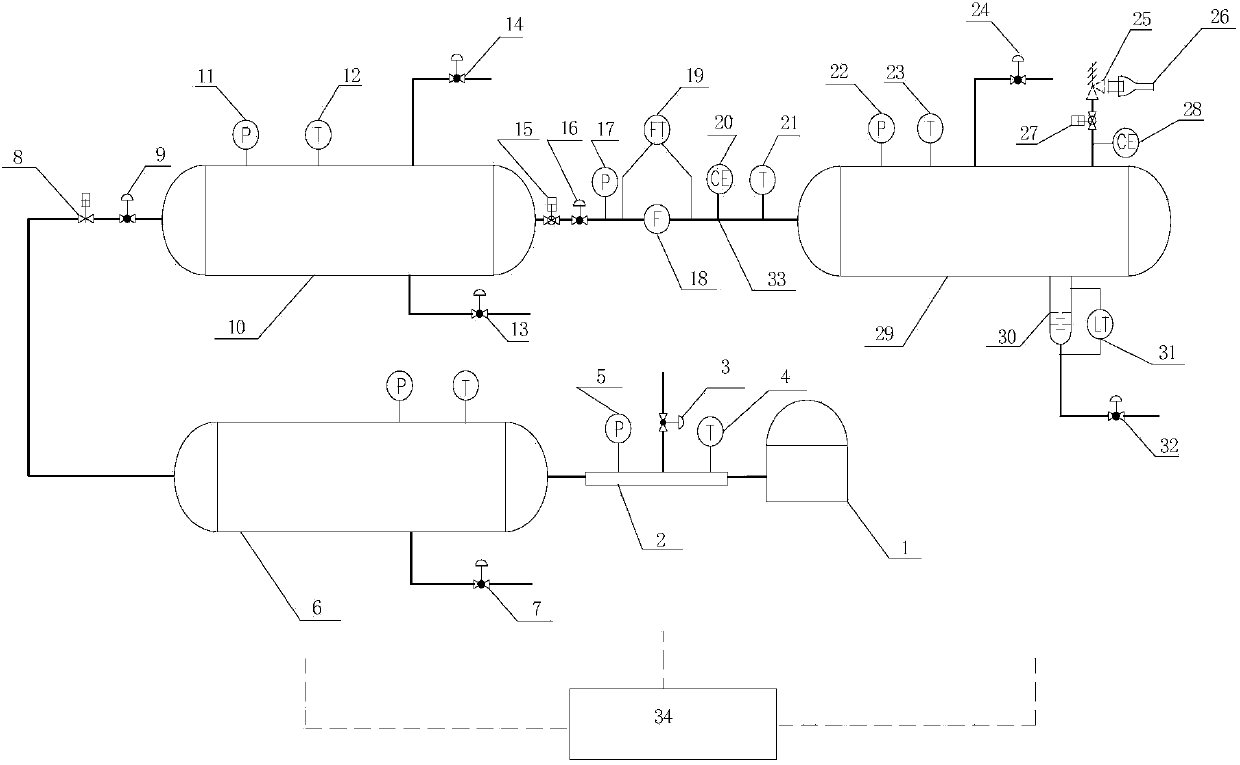

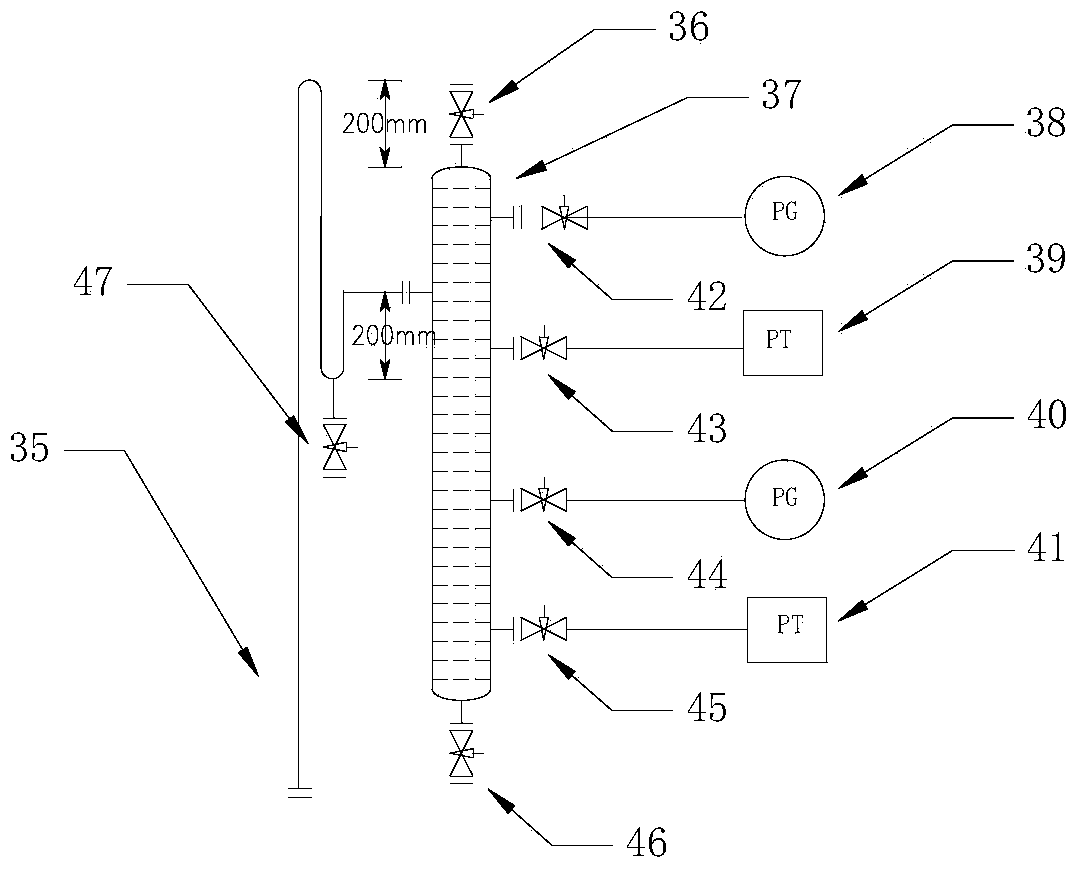

Method used

Image

Examples

Embodiment

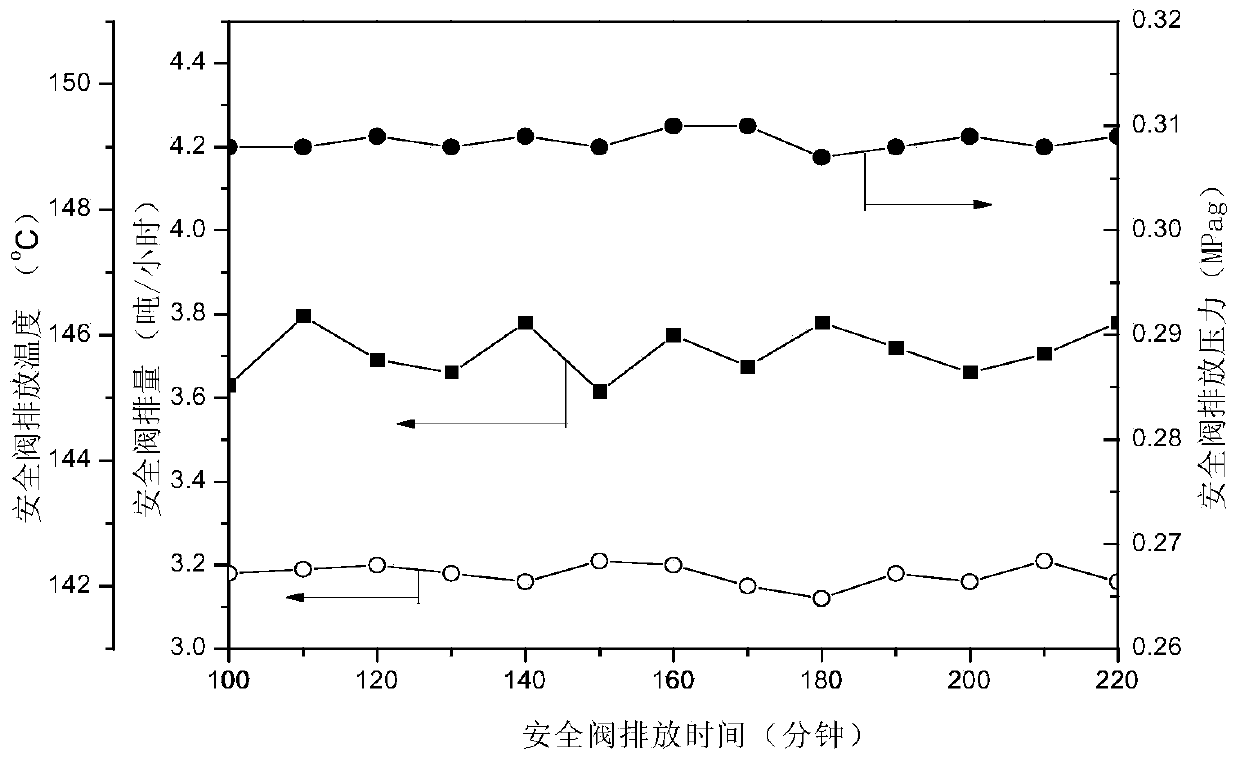

[0059] Tested valve: steam safety valve, the set pressure is 0.3MPag, the nominal diameter of the safety valve is 75mm, and the rated displacement is 3.16 tons / hour.

[0060] (1) The once-through boiler is started in a cold state, boiler water enters the boiler, and the pneumatic control valve below the steam-water separator is opened to discharge condensed water;

[0061] (2) After the once-through boiler is ignited, the steam is gradually generated, and the outlet pressure of the boiler reaches 7MPag by adjusting the opening of the regulating valve on the steam header; Open the pneumatic regulating valve at the bottom of the container to discharge the condensed water after about 1 hour. During the preheating and boosting process, the temperature of the inner and outer walls of the container should not exceed 50°C;

[0062] (3) When the pressure of the accumulator and the test vessel reaches 0.24MPag, close the pneumatic ball valve at the entrance of the test vessel and stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com