Modified wood chip adsorbent, and preparation method and application thereof in treating wastewater containing basic dye

A basic dye and adsorbent technology, applied in the field of water pollution treatment, can solve the problems of high manufacturing cost, limited source of raw materials, low adsorption capacity, etc., and achieve the effects of small usage, low cost and high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

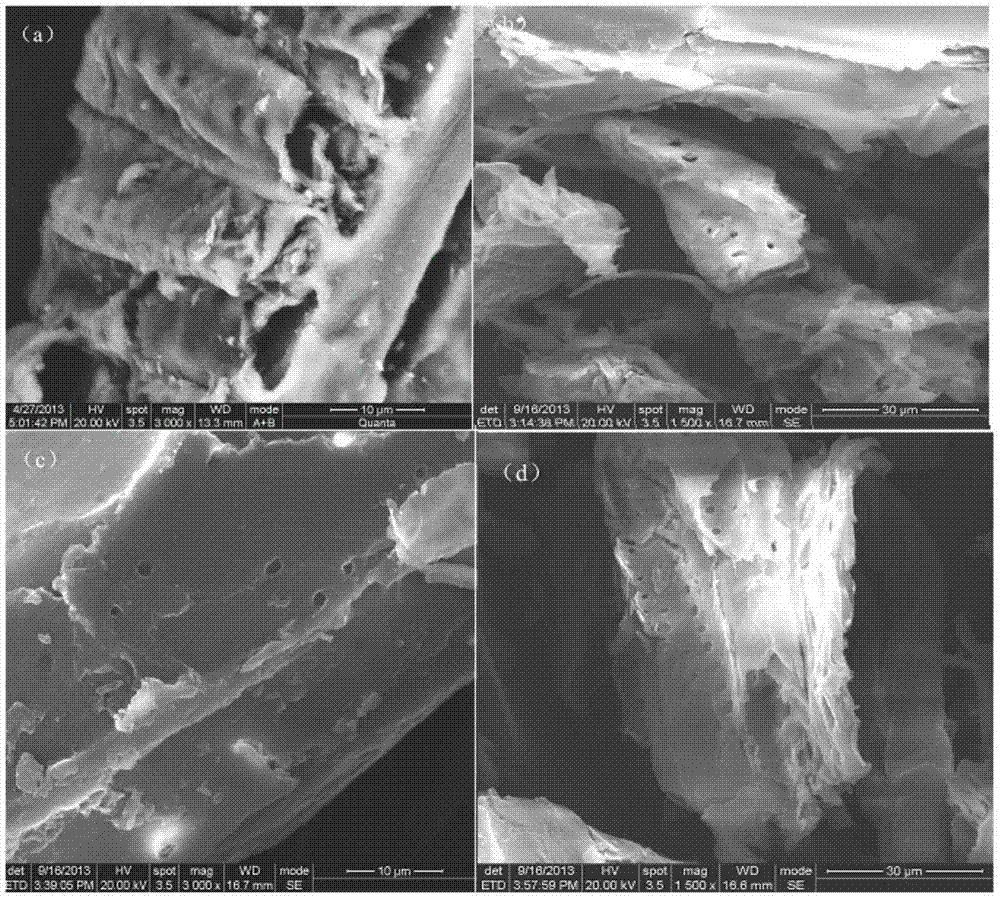

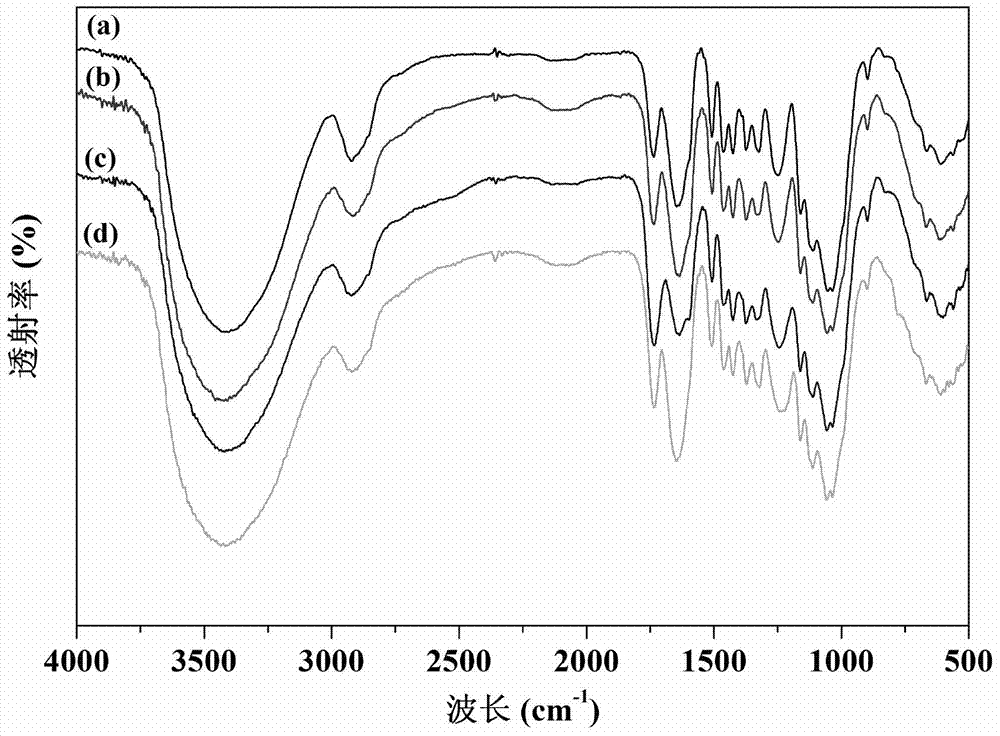

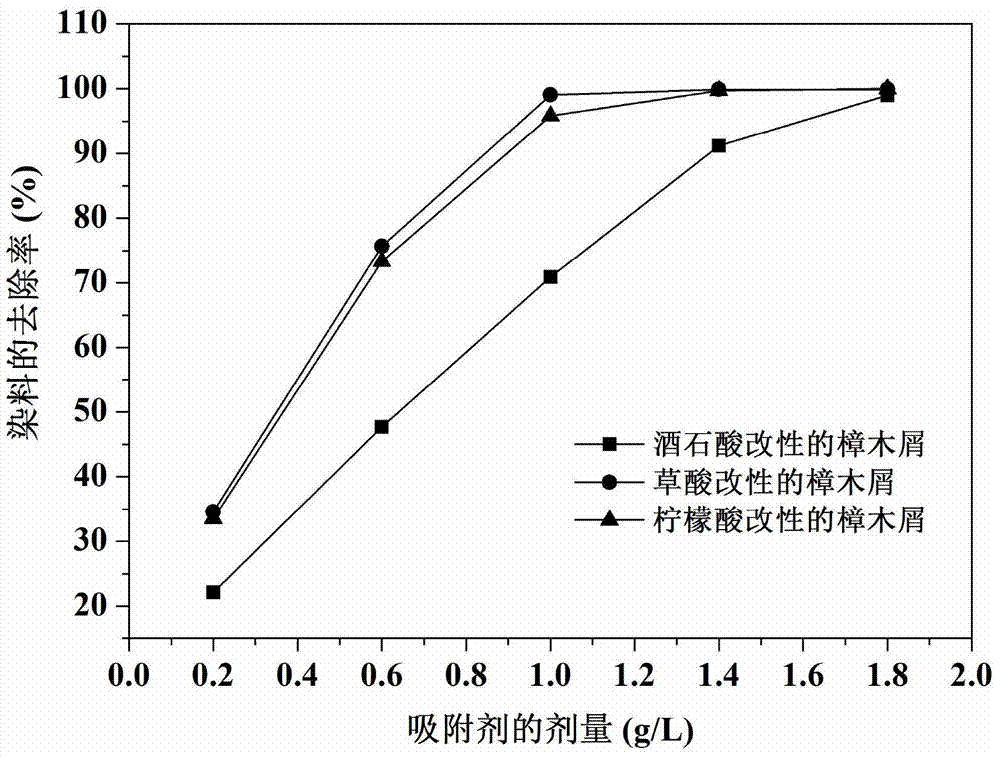

[0025] The preparation method of modified sawdust adsorbent is as follows:

[0026] (1) Collect waste camphor wood chips from wood processing plants, put 500g of camphor wood chips into a large beaker, add deionized water to wash and filter, repeat 3 times until the filtrate becomes clear and free of turbidity, and after solid-liquid separation, get Wet camphor wood chips were placed in a drying box, and dried to constant weight for 24 hours to obtain dry camphor wood chips. Using a high-speed pulverizer, crush the dry camphor wood chips obtained above into powder, and sieve to keep the particle size of the camphor wood chips between 45-75 mm to obtain the camphor wood chips powder. Take 10 g of camphor sawdust powder, add it to 200 mL of 1.1 mol / L oxalic acid solution, and shake at room temperature for 3 hours at a shaking speed of 200 rpm.

[0027] (2) After the reaction, the solid and liquid were separated, and the solids were dried at 60°C for 24 hours.

[0028] (3) The ...

Embodiment 2

[0032] The preparation method of modified sawdust adsorbent is as follows:

[0033] (1) Collect waste camphor wood chips from wood processing plants, put 500g of camphor wood chips into a large beaker, add deionized water to wash and filter, repeat 3 times until the filtrate becomes clear and free of turbidity, and after solid-liquid separation, get Wet camphor wood chips were placed in a drying box, and dried to constant weight for 24 hours to obtain dry camphor wood chips. Using a high-speed pulverizer, crush the dry camphor wood chips obtained above into powder, and sieve to keep the particle size of the camphor wood chips between 45-75 mm to obtain the camphor wood chips powder. Take 10 g of camphor sawdust powder, add it to 180 mL of 1.2 mol / L tartaric acid solution, and shake at room temperature for 3 hours at a shaking speed of 200 rpm.

[0034] (2) After the reaction, the solid and liquid were separated, and the solids were dried at 60°C for 24 hours.

[0035] (3) Th...

Embodiment 3

[0039] The preparation method of modified sawdust adsorbent is as follows:

[0040] (1) Collect waste camphor wood chips from wood processing plants, put 500g of camphor wood chips into a large beaker, add deionized water to wash and filter, repeat 3 times until the filtrate becomes clear and free of turbidity, and after solid-liquid separation, get Wet camphor wood chips were placed in a drying box, and dried to constant weight for 24 hours to obtain dry camphor wood chips. Using a high-speed pulverizer, crush the dry camphor wood chips obtained above into powder, and sieve to keep the particle size of the camphor wood chips between 45-75 mm to obtain the camphor wood chips powder. Take 10 g of camphor sawdust powder, add it to 240 mL of 1.0 mol / L citric acid solution, and shake at room temperature for 3 hours at a shaking speed of 200 rpm.

[0041](2) After the reaction, the solid and liquid were separated, and the solids were dried at 60°C for 24 hours.

[0042] (3) Raise...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com