Transition metal oxide/binary carbon network positive electrode composite material and aluminum-ion battery

An aluminum ion battery and transition metal technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of poor structural stability and low conductivity, and achieve high power performance, high conductivity, and good compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

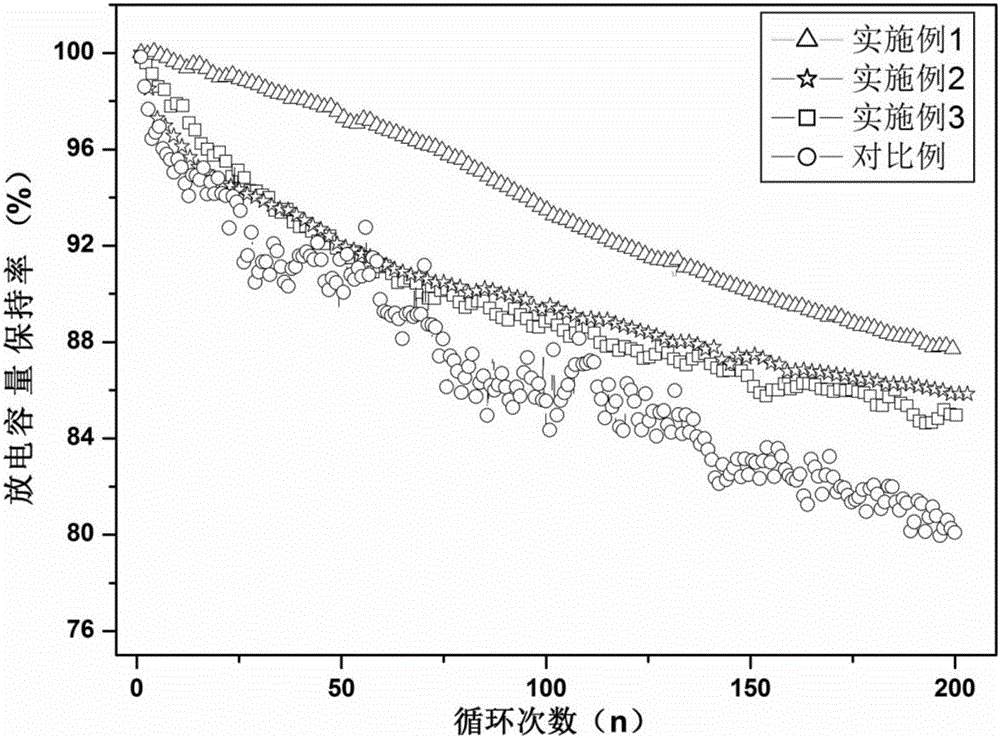

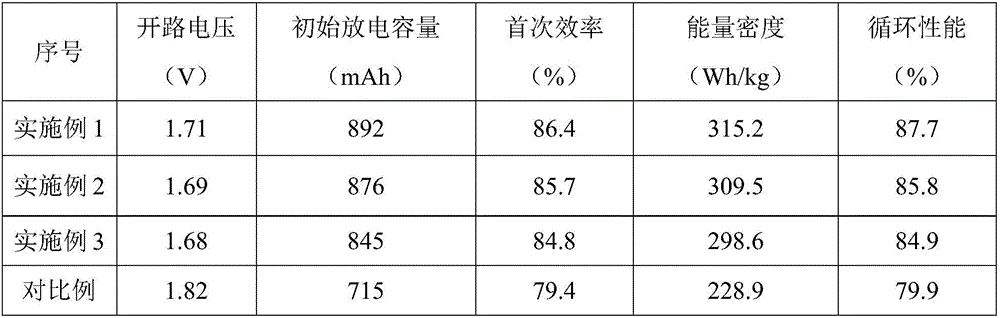

Examples

Embodiment 1

[0030] The transition metal oxide / binary carbon mesh positive electrode composite material of this embodiment is prepared by the following steps:

[0031] 1) Add 0.5g of iron and 5g of citric acid into 100g of water and mix to obtain a catalyst precursor solution;

[0032] 2) 10g TiO 2 Soak in the catalyst precursor solution for 2 hours, separate, and then dry at 100°C for 2 hours; repeat the soaking and drying process 5 times to obtain TiO 2 / Catalyst precursor composite material;

[0033] 3) Put 8g TiO 2 / Catalyst precursor composite material is placed in the middle of the tubular resistance furnace, under the protection of argon, the temperature is raised to 800°C at a rate of 3°C / min and kept for 2h, and the hydrogen is used to reduce the catalyst precursor (the time for introducing hydrogen is 30min, The flow rate is 100ml / min); the temperature is lowered to 700°C and kept for 2 hours, and the mixed gas of acetylene as the carbon source gas and argon as the carrier ga...

Embodiment 2

[0038] A transition metal oxide / binary carbon mesh positive electrode composite material in this embodiment is prepared by the following steps:

[0039] 1) Add 0.1g of nickel and 1g of citric acid into 100g of water and mix to obtain a catalyst precursor solution;

[0040] 2) 1g Cr 2 o 3 Soak in the catalyst precursor solution for 1 hour, separate, and then dry at 50°C for 2 hours; repeat soaking and drying once to obtain Cr 2 o 3 / Catalyst precursor composite material;

[0041] 3) 1g Cr 2 o 3 / The catalyst precursor composite material is placed in the middle of the tubular resistance furnace, under the protection of argon, the temperature is raised to 800°C at a rate of 1°C / min, and then kept for 1h, and the catalyst precursor is reduced by hydrogen (the time for introducing hydrogen is 1h , the flow rate is 50ml / min); the temperature is lowered to 700°C and kept for 1h, and the mixed gas of acetylene as the carbon source gas and argon as the carrier gas is introduced...

Embodiment 3

[0046] A transition metal oxide / binary carbon mesh positive electrode composite material in this embodiment is prepared by the following steps:

[0047] 1) Add 1g of cobalt and 10g of citric acid into 100g of water and mix to obtain a catalyst precursor solution;

[0048] 2) 20g MnO 2 Soak in the catalyst precursor solution for 2 hours, separate, and then dry at 200°C for 1 hour; repeat the soaking and drying process 10 times to obtain MnO 2 / Catalyst precursor composite material;

[0049] 3) 20g MnO 2 / The catalyst precursor composite material is placed in the middle of the tubular resistance furnace, under the protection of argon, the temperature is raised to 800°C at a rate of 5°C / min, and then kept for 1h, and the catalyst precursor is reduced (the time for introducing hydrogen is 2h, The flow rate is 150ml / min); the temperature is lowered to 700°C and kept for 1h, and the mixed gas of acetylene as the carbon source gas and argon as the carrier gas is introduced for c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com