Durable and easy-care fine denier hollow polyester imitation silk woven fabric products

An easy-care, durable technology, applied in the direction of fabrics, bleached products, textiles and papermaking, etc., can solve the problems of uneven dyeing, easy staining of knitted fabrics, difficult to remove dirt, etc., and achieve low color fastness, Enhance reduction cleaning and improve the effect of chlorine washing fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

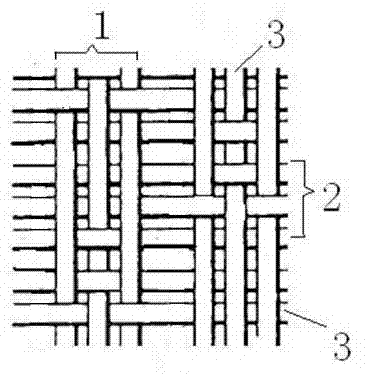

[0034] Such as figure 1 As shown, the durable and easy-to-care fine denier hollow polyester imitation silk shuttle fabric products, the warp direction is 1.0-1.3dex special-shaped cross-section hollow polyester filament 3, and the weft direction is 1.0-1.3dex special-shaped cross-section hollow polyester filament 3; Three hollow polyester filaments 3 with special-shaped cross-section form a warp weave unit 1; every three hollow polyester filaments 3 with special-shaped cross-section form a weft weave unit 2; the distance between adjacent warp-weave units 1 is 0.3mm, The spacing of 2 is 0.25mm; the sum of warp and weft yarns per square inch of woven fabric products is 250. The hollow polyester filament 3 with special-shaped cross-section has a triangular cross-section. The hollow polyester filament with special-shaped cross-section 3 has a specification of 180D. The distance between adjacent hollow polyester filaments 3 with special-shaped cross-sections in each weaving unit ...

Embodiment 2

[0042] Durable and easy-to-care fine denier hollow polyester imitation silk shuttle fabric products, special-shaped cross-section hollow polyester filaments 3 with a warp direction of 1.0-1.3dex, and special-shaped cross-section hollow polyester filaments 3 with a weft direction of 1.0-1.3dex; every 3 special-shaped Cross-sectional hollow polyester filaments 3 form a warp-knit unit 1; every three hollow polyester filaments 3 with special-shaped cross-sections form a weft-knit unit 2; the distance between adjacent warp-knit units 1 is 0.5 mm, and the distance between adjacent weft-knit units 2 It is 0.4mm; the total number of warp and weft yarns per square inch of woven fabric products is 330. The hollow polyester filament 3 with special-shaped cross-section has an elliptical cross-section. The hollow polyester filament with special-shaped cross-section 3 has a specification of 180D. The distance between adjacent hollow polyester filaments 3 with special-shaped cross-sections ...

Embodiment 3

[0050] Durable and easy-to-care fine denier hollow polyester imitation silk shuttle fabric products, special-shaped cross-section hollow polyester filaments 3 with a warp direction of 1.0-1.3dex, and special-shaped cross-section hollow polyester filaments 3 with a weft direction of 1.0-1.3dex; every 3 special-shaped Sectional hollow polyester filaments 3 form a warp weave unit 1; every three hollow polyester filaments 3 with special-shaped cross sections form a weft weave unit 2; the distance between adjacent warp weave units 1 is 0.4mm, and the distance between adjacent weft weave units 2 It is 0.3mm; the sum of warp and weft yarns per square inch of woven fabric products is 290. The hollow polyester filament 3 with special-shaped cross-section has a diamond-shaped cross-section. The hollow polyester filament with special-shaped cross-section 3 has a specification of 180D. The distance between adjacent hollow polyester filaments 3 with special-shaped cross-sections in each w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com