Preparation method of fouling resistant coating for highway barrier

A highway, stain-resistant technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor coating film leveling, high maintenance costs, easy to be polluted, loss of gloss and self-cleaning ability, etc. Improved weatherability, good adhesion, and improved self-cleaning and anti-fouling properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The preparation of the hydroxyacrylic acid water dispersion a of embodiment 1 containing phosphate group

[0062] Add 1.00 kg of propylene glycol butyl ether and 1.00 kg of glycidyl tert-carbonate into a reactor equipped with a mechanical stirring device and a nitrogen device, and feed in nitrogen gas while raising the temperature until the temperature reaches 100°C; after the temperature stabilizes, start adding peroxide 275g tert-amyl acetate, 100g dodecyl mercaptan, 2.00kg methyl methacrylate, 2.80kg butyl acrylate, 1.50kg styrene, 2.03kg hydroxyethyl methacrylate, 670g acrylic acid, phosphoethyl methacrylate 1.50kg of ester monomer mixture, control the dropping speed of the monomer to make it drop within 2 to 3 hours; immediately add 25g of initiator tert-amyl peroxyacetate; continue to keep warm for 2 hours, measure the hydroxy acrylate The conversion rate of the resin is over 98%, and the hydroxy acrylic resin containing phosphate groups is obtained. When the tem...

Embodiment 2

[0065] The preparation of the hydroxyacrylic acid aqueous dispersion b of embodiment 2 containing phosphate group

[0066] Add 1.00kg of propylene glycol methyl ether acetate and 0.90kg of glycidyl tertiary carbonic acid ester into a reactor equipped with a mechanical stirring device and a nitrogen device, and feed in nitrogen gas while raising the temperature until the temperature reaches 100°C; after the temperature stabilizes, start to drop 275g tert-amyl peroxybenzoate, 100g mercaptoethanol, 2.50kg methyl methacrylate, 2.30kg butyl acrylate, 1.60kg styrene, 2.20kg hydroxyethyl methacrylate, 0.67kg methacrylic acid, methacrylic acid Propyl phosphate 0.80kg monomer mixture, control the drop rate of the monomer, so that it will be dripped within 2 to 3 hours; immediately add 25 g of initiator tert-amyl peroxybenzoate; continue to keep warm for 2 hours, measure The conversion rate of the hydroxyacrylic acid ester resin is over 98%, and the hydroxyacrylic acid resin containing ...

Embodiment 3

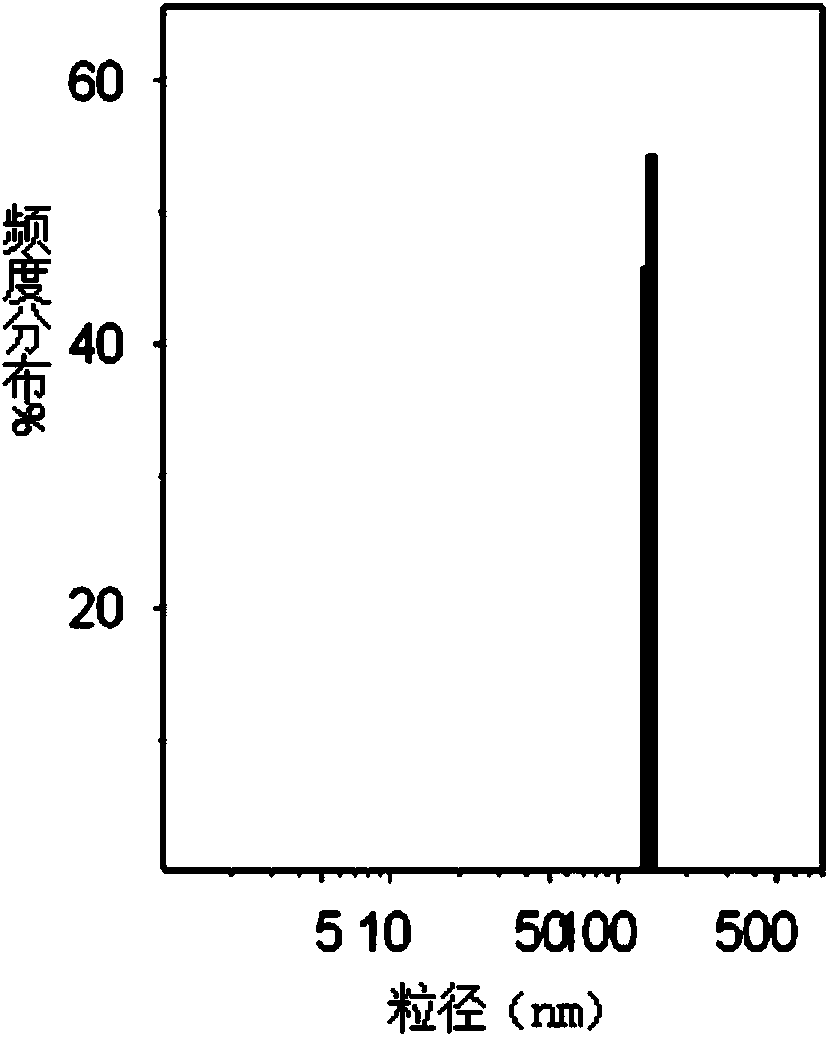

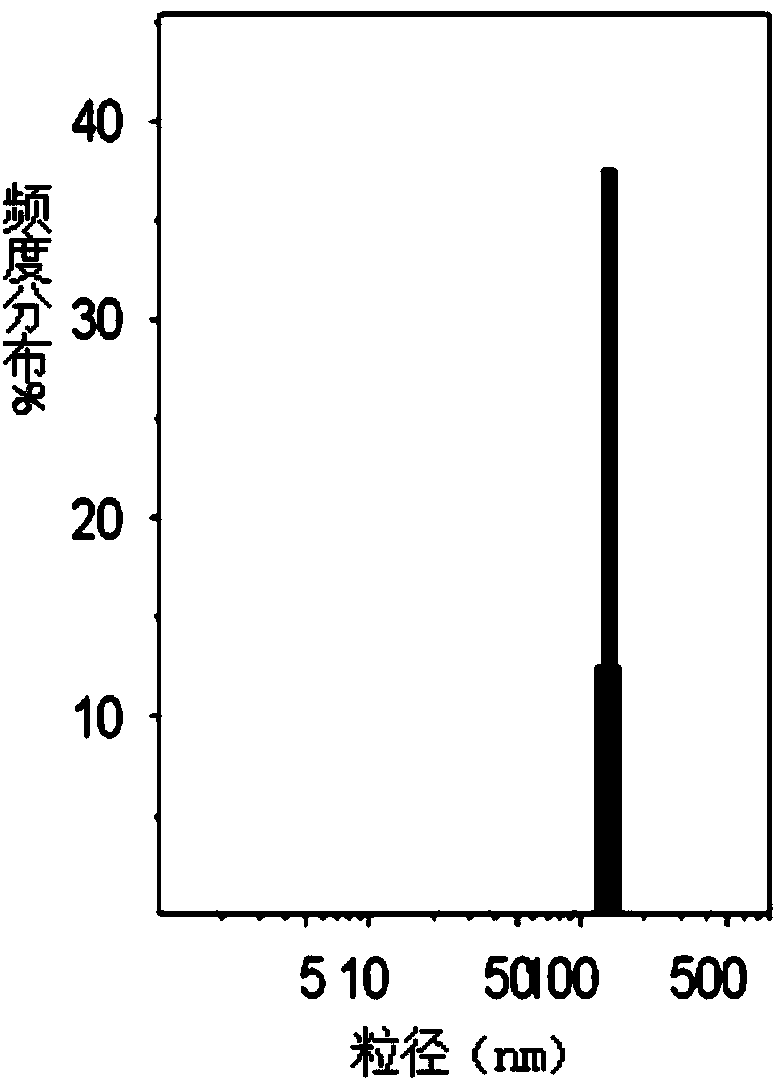

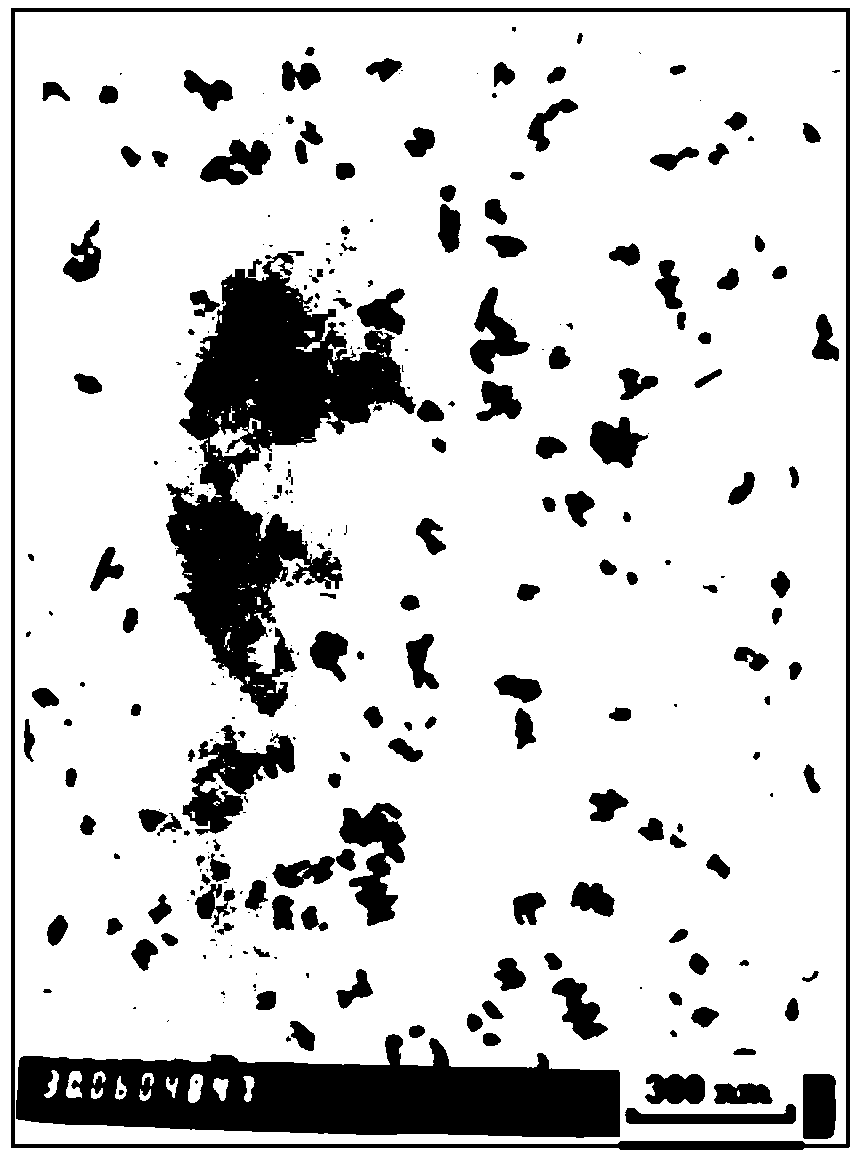

[0069] Example 3 Nano TiO 2 Preparation of dispersion slurry a

[0070]First, add 8.0Kg of water, 11.60kg of the acrylic acid aqueous dispersion containing phosphate groups in Example 1 to the dispersion kettle and make it evenly stirred, then add 400g of BYK-P104S dispersant to the kettle while gradually adding Hombitec RM220 Nano-TiO 2 Powder 14.00kg and propylene glycol methyl ether acetate 6.0Kg, to be nano-TiO 2 After the powder is added, the mixer stirs at a speed of 800r / min for about 30-40min until the agglomerated particles of the powder basically disappear; then use the gear stirring shaft to shear and stir at a speed of 4000r / min for 1-2 hours until the fineness reaches about 15μm Finally, the LMZ2 circulating agitation sand mill of Netzsch Company was used to grind the composite nanoparticle dispersion slurry for 2 hours under the conditions of zirconium bead particle size 0.4mm, zirconium bead loading amount of 70%, and rotation speed of 2500r / min. .

[0071] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com