Oxo-vanadium phosphate catalyst, and preparation method and application thereof

A technology of vanadyl phosphate catalyst and solvent, which is used in the oxidation preparation of carbonyl compounds, chemical instruments and methods, catalysts for physical/chemical processes, etc. Safety hazard, stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of vanadyl phosphate catalyst, its step is:

[0024](1) Preparation of ionic liquids and eutectic mixtures, such as the synthesis of 1-alkyl-3-methylimidazolium bromides as [Emim]Br and [Bmim]Br from N-methylimidazole and the corresponding brominated The alkanes are reacted at 30°C-70°C for 3-10 hours, then washed several times with ethyl acetate, and dried in vacuum; the eutectic mixture is obtained by mixing and melting choline chloride and urea or other similar substances; chlorination The mixing molar ratio of choline and urea is 1:1~1:5;

[0025] (2) To prepare the vanadyl phosphate precursor, put the phosphorus source and the vanadium source into the ionic liquid and the eutectic mixture at a certain ratio, and the molar ratio of the ionic liquid solvent to the vanadium is 20-40; during the synthesis process, it is necessary to add A small amount of mineralizer, the synthesis temperature is 120-180°C, normal pressure, and the reaction time ...

Embodiment 1

[0030] Example 1: Add 40.51 g of choline chloride and 34.83 g of urea into a reaction vessel, melt at 80°C, continue to add 5.0 g of 85% phosphoric acid, 5.08 g of ammonium metavanadate, and 1.13 g of ammonium fluoride, and heat up to 120°C for reaction 12 h, washed with water and ethanol, and filtered to obtain a brown-black solid.

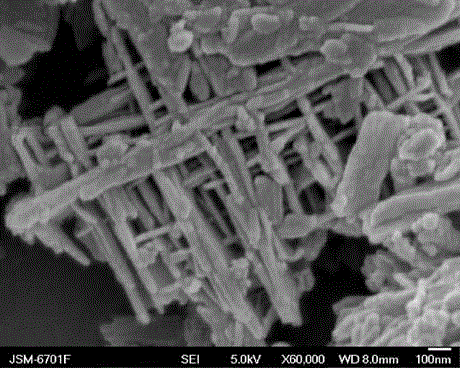

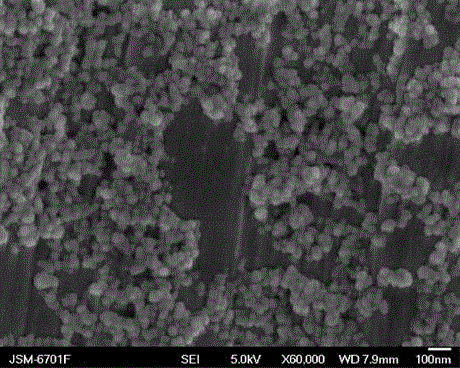

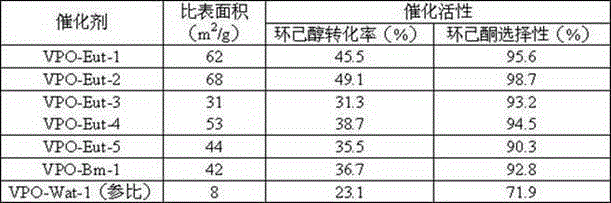

[0031] Post-treatment: drying at 110°C, and air calcination at 400°C for 4 h to obtain a vanadyl phosphate catalyst, which is denoted as VPO-Eut-1, such as figure 1 As shown, the material prepared by this method exhibits a rod-like morphology, most of which have a diameter of 20-50 nm. The specific surface area is shown in Table 1.

Embodiment 2

[0032] Example 2: 25.08 g of 85% phosphoric acid, 2.54 g of ammonium metavanadate, and 0.56 g of ammonium fluoride were added to the reaction vessel, and the temperature was raised to 180° C. for 144 h. Others were the same as in Example 1.

[0033] Post-treatment: drying at 110°C, followed by air calcination at 450°C for 6 h to obtain a vanadyl phosphate catalyst, which is designated as VPO-Eut-2. The specific surface area is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com