Ultrasonic probe, medical endoscope and processing method for ultrasonic probe and medical endoscope

An ultrasonic probe and endoscope technology, applied in the field of medical endoscopes and ultrasonic probes, can solve the problems of shortening the service life of the probe, poor chemical resistance, corrosion of solder joints, etc. Impact capability, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The embodiment of the present invention provides a durable and not easily damaged ultrasonic probe and medical endoscope.

[0046] like Figure 5 , 6 As shown, they are the schematic structural diagrams of the medical endoscope 1 and the ultrasonic probe 2 respectively. Both the medical endoscope probe and the ultrasonic probe have acoustic lenses 11 and 21 at the front end respectively, and the acoustic lenses 11 and 12 usually have a hardness of about 55A. silicone rubber material. Most of the insertion tube 12 of the endoscope is made of polyurethane. Endoscopes and ultrasound probes generally use PVC cable sheaths with relatively high cost performance13, 22, some manufacturers use polyurethane cable sheaths, and a few high-quality endoscopes and ultrasound probes use silicon. Cable with rubber sheath.

[0047]

[0048] The solution described in the specific embodiment of the present invention is to arrange a layer of protective film on the outer surface of the u...

Embodiment 2

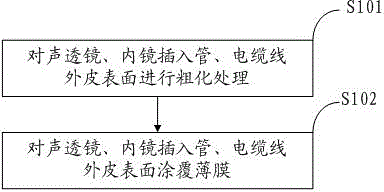

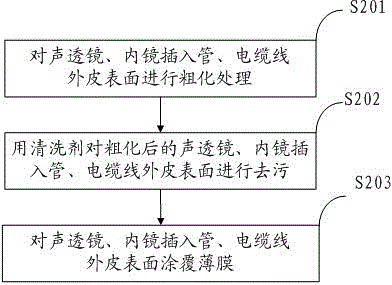

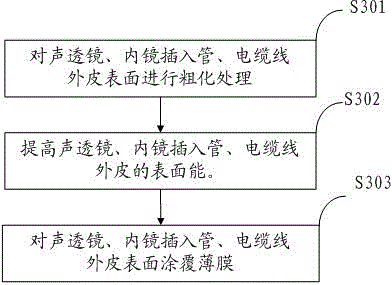

[0057] like figure 1 As shown, the present invention also provides a method (hereinafter referred to as the method) for setting a protective film on the surface of the ultrasonic probe, the acoustic lens of the medical endoscope, the endoscope insertion tube thereof, and the outer skin of the cable (hereinafter referred to as the method), and the method includes the following steps:

[0058] S101. Roughen the surface of the acoustic lens, its endoscope insertion tube, and the outer skin of the cable.

[0059] The specific method of the roughening treatment can use the physical roughening method. In this specific embodiment, the sandblasting method is preferred, and the insertion tube, the cable sheath and the surface of the acoustic lens are roughened, and the angle of the sandblasting is controlled at 25-75°. °, the particle size of the sand is selected at 400-900 mesh. After roughening, use compressed air to blow off the sand, and then repeatedly wipe the surface with deio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com