Ultraviolet-proof electric wire and cable material and preparation method thereof

A wire and cable material, anti-ultraviolet technology, applied in the field of anti-ultraviolet wire and cable material and its preparation, can solve the problems of poor anti-ultraviolet, economic loss, etc., achieve huge economic prospects and social benefits, improve light aging resistance, good physical and mechanical performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

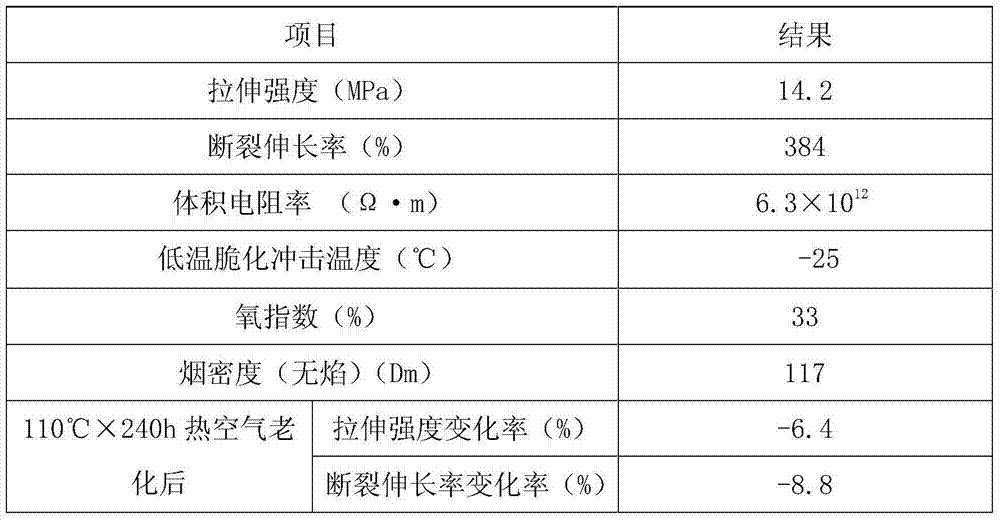

Examples

Embodiment Construction

[0012] An anti-ultraviolet wire and cable material, made of the following raw materials by weight (kg): SG-2 type PVC80, polyethylene terephthalate 25, bisphenol A polycarbonate 12, 4,4' diphenyl Methane diisocyanate 1.5, jade powder 6, diphenyl isooctyl phosphate 4, tribasic lead sulfate 1, polyethylene wax 2, processing aid ACR-4012, ultraviolet absorber UV-5311.5, ultraviolet absorber UV-90.8, Talc powder 12, ammonium polyphosphate 6, nano sepiolite 8, magnesium sulfate whisker 12, composite filler 5;

[0013] The preparation method of the composite filler is as follows: a. Take the following raw materials in parts by weight: bauxite 15, barite 10, nano-titanium nitride 6, vinyltriethoxysilane 1.5, nano-zinc powder 2, red mud 5. Stearic acid 2. Antioxidant 10351.5; b. Calcinate kaolin and lapis lazuli at 530°C for 4 hours, cool to room temperature, add appropriate amount of water together with nano-titanium nitride and red mud to grind, and heat in a water bath at 80°C 1h,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com