Preparation method of WCu composite powder with tungsten coating copper

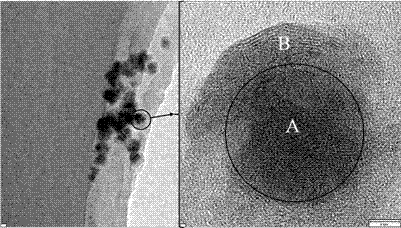

A composite powder and copper-clad technology, applied in coatings and other directions, can solve problems such as no progress in research, and achieve the effects of small particles, simple process and easy operation, and improved recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of WCu composite powder with tungsten-coated copper phenomenon adopts the following production steps:

[0025] Step 1. Weigh sodium tungstate dihydrate and copper nitrate trihydrate according to the atomic concentration ratio of W and Cu as 1:1, prepare them into solutions with a concentration of 0.8mol / L respectively, and add them to the obtained copper nitrate trihydrate solution Add ammonia water and make it fully mixed at 30°C to generate sufficient copper complex ions in the solution, then add the prepared sodium tungstate dihydrate solution, and then add nitric acid to adjust the pH value of the mixed solution to 5.2- 6.2, and fully stir in a magnetic stirrer for 2 hours before use;

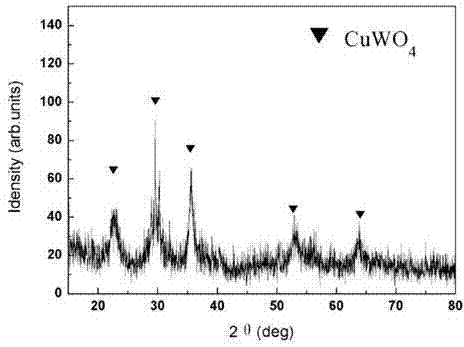

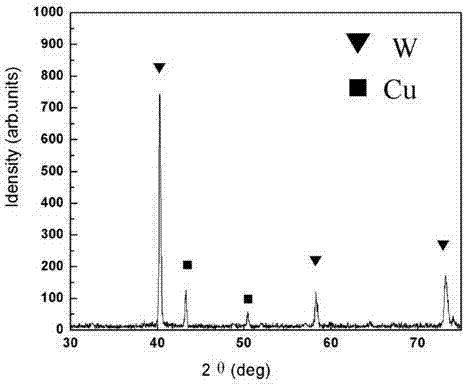

[0026] Step 2. Put the mixed solution obtained in step 1 into a stainless steel reactor. The amount of the mixed solution is 80% of the volume of the stainless steel reactor. After reacting at a temperature of 150° C. for 48 hours, the furnace is cooled to room t...

Embodiment 2

[0031] A preparation method of WCu composite powder with tungsten-coated copper phenomenon adopts the following production steps:

[0032] Step 1. Weigh sodium tungstate dihydrate and copper nitrate trihydrate according to the atomic concentration ratio of W and Cu as 1:1, prepare them into solutions with a concentration of 0.8mol / L respectively, and add them to the obtained copper nitrate trihydrate solution Add ammonia water and make it fully mixed at 30°C to generate sufficient copper complex ions in the solution, then add the prepared sodium tungstate dihydrate solution, and then add nitric acid to adjust the pH value of the mixed solution to 5.2- 6.2, and fully stir in a magnetic stirrer for 4 hours before use;

[0033] Step 2. Put the mixed solution obtained in step 1 into a stainless steel reactor. The amount of the mixed solution is 80% of the volume of the stainless steel reactor. After reacting at a temperature of 170° C. for 35 hours, the furnace is cooled to room t...

Embodiment 3

[0038] A preparation method of WCu composite powder with tungsten-coated copper phenomenon adopts the following preparation steps:

[0039] Step 1. Weigh sodium tungstate dihydrate and copper nitrate trihydrate according to the atomic concentration ratio of W and Cu as 1:1, prepare them into solutions with a concentration of 0.8mol / L respectively, and add them to the obtained copper nitrate trihydrate solution Add ammonia water and make it fully mixed at 30°C to generate sufficient copper complex ions in the solution, then add the prepared sodium tungstate dihydrate solution, and then add nitric acid to adjust the pH value of the mixed solution to 5.2- 6.2, and fully stir in a magnetic stirrer for 5 hours before use;

[0040] Step 2. Put the mixed solution obtained in step 1 into a stainless steel reactor. The amount of the mixed solution is 80% of the volume of the stainless steel reactor. After reacting at a temperature of 180° C. for 24 hours, the furnace is cooled to room ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com