Method for transforming 1,3-propylene glycol into 3-hydroxypropionic acid by applying resting cells

A technology of hydroxypropionic acid and propylene glycol, applied in the field of bioengineering, can solve the problems of long production cycle, unstable bacterial species in fermentation method, and many side reactions, save energy and production costs, facilitate product separation and purification, and transform liquid components. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

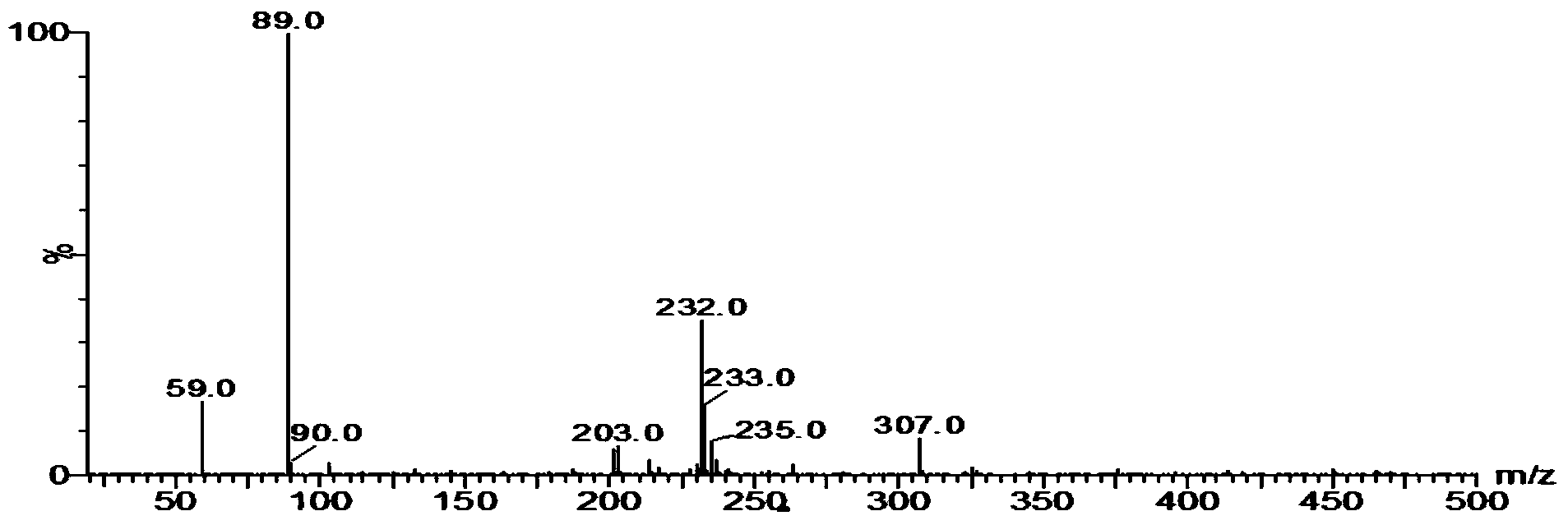

[0022] Example 1 High conversion of 1,3-propanediol performance, screening of microbial strains with high ability to produce 3-hydroxypropionic acid

[0023] Enrichment medium (g / L): glucose 20, yeast extract 5, peptone 2.

[0024] Plate screening medium (g / L): Glucose 20, yeast extract 5, agar 20, CaCO310 (added after sterilization alone), absolute ethanol 30 (added after the medium is sterilized).

[0025] Seed medium, fermentation medium (g / L): glucose 20, yeast extract 5, peptone 2, pH 6.0.

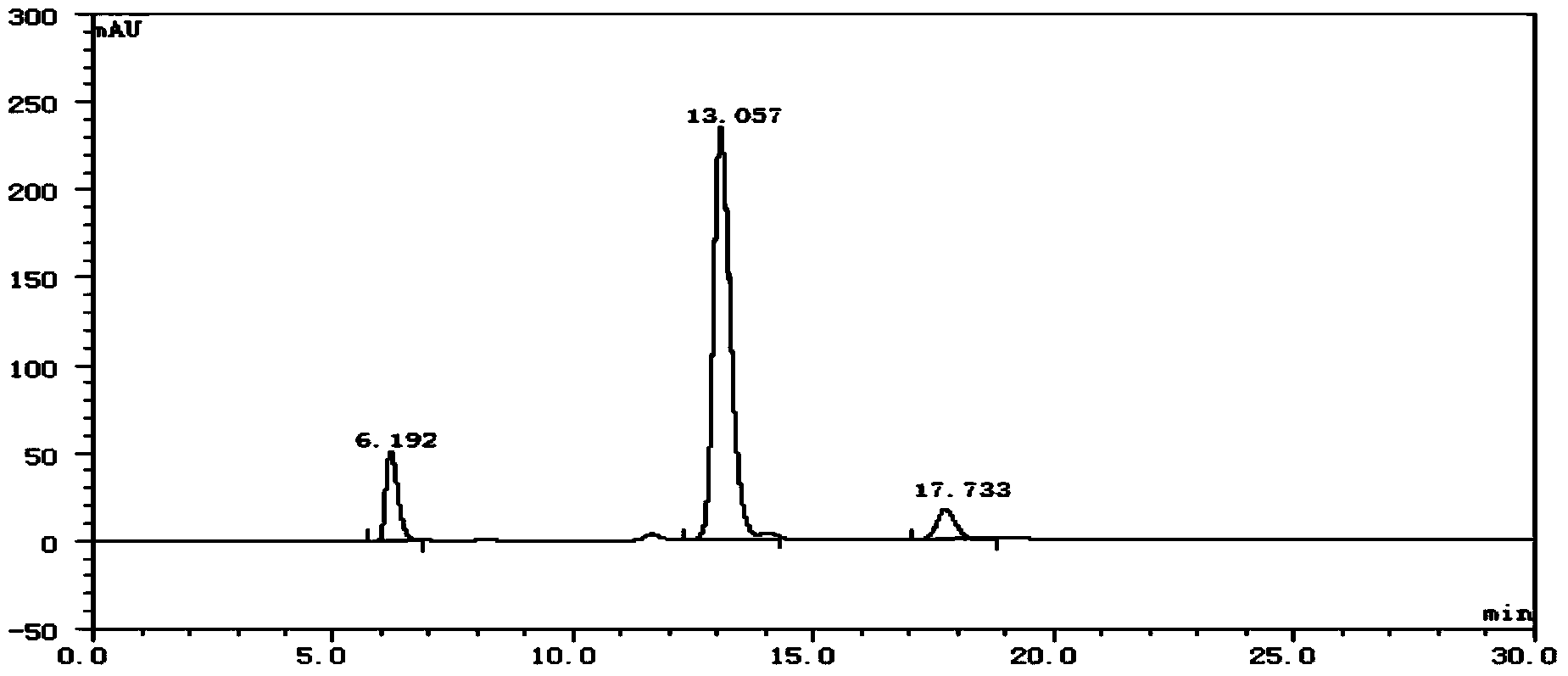

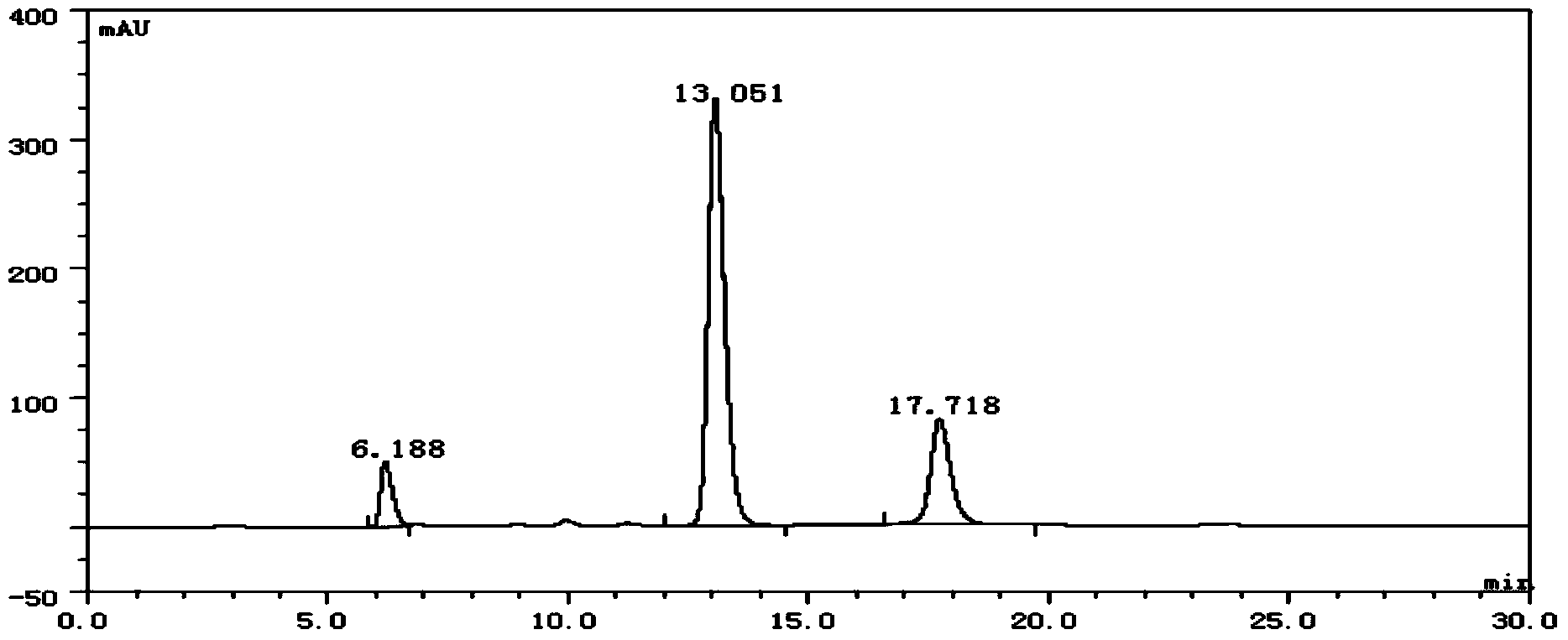

[0026] Analysis method: detection of 3-hydroxypropionic acid by HPLC, chromatographic column: BIORAD HPX-87H chromatographic column; mobile phase 0.005mol / L concentrated sulfuric acid; flow rate 0.6mL / min; detection temperature 60°C; detection wavelength 210nm.

[0027] Add the collected soil from different regions into sterile saline solution containing glass beads and shake for 1 hour, then let it stand still, take the supernatant and add it to the enrichment medium for static cult...

Embodiment 2

[0031] The impact of embodiment 2 different substrate concentrations on conversion

[0032]Centrifuge the cells cultivated in the fermentation medium for 32 hours, wash the cells twice with a phosphate buffer solution of pH 6.0, suspend the cells with a phosphate buffer solution of pH 6.0, and make the cell concentration 6g / L Add different amounts of substrate 1,3-propanediol to the bacterial suspension, so that the final concentrations are 10g / L, 20g / L, 30g / L, 40g / L, 50g / L, and catalyze at 30°C and 220rpm Sampling within 72 hours, the transformation solution was centrifuged to remove bacteria, filtered through a 0.22um aqueous phase membrane, and tested by HPLC to detect its yield, the yield can reach 9.6g / L, 18.9g / L, 27.7g / L, 35.9g / L L, 45.5g / L, the conversion rate is above 90% (attached Figure 5 ).

Embodiment 3

[0033] The influence of embodiment 3 different initial pHs on conversion

[0034] After centrifuging the bacteria cultured in the fermentation medium for 32 hours, use pH4.0, pH4.5, pH5.0, pH5.5, pH6.0, pH6.5, pH7.0, pH7.5, pH8.0 respectively After washing the cells twice with the buffer solution, suspend the cells with the buffer solution of the corresponding pH to make a cell suspension with a cell concentration of 6 g / L, add 20 g / L of 1,3-propanediol, and measure at 220 rpm at 30 °C. The amount of 3-hydroxypropionic acid produced after 6h of catalysis was taken as its initial catalytic rate. The catalytic rate is the highest at around pH 6.0, which can reach 1.1g / L*h. The acidic or alkaline pH will cause the catalytic rate to decrease, and the catalytic rate will decrease by about 40% at around pH 4.0 (attached Image 6 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com