Halogen-free flame-retardant highly-heat-resistant unsaturated polyester glass fiber composite material

A technology of polyester glass fiber and composite materials, which is applied in the field of insulating materials, can solve problems such as personal safety and property loss, increased fires, and failure to meet high-strength requirements, etc., to achieve guaranteed loss-free, effective flame retardancy, and excellent abnormal conditions and the effect of thermal mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

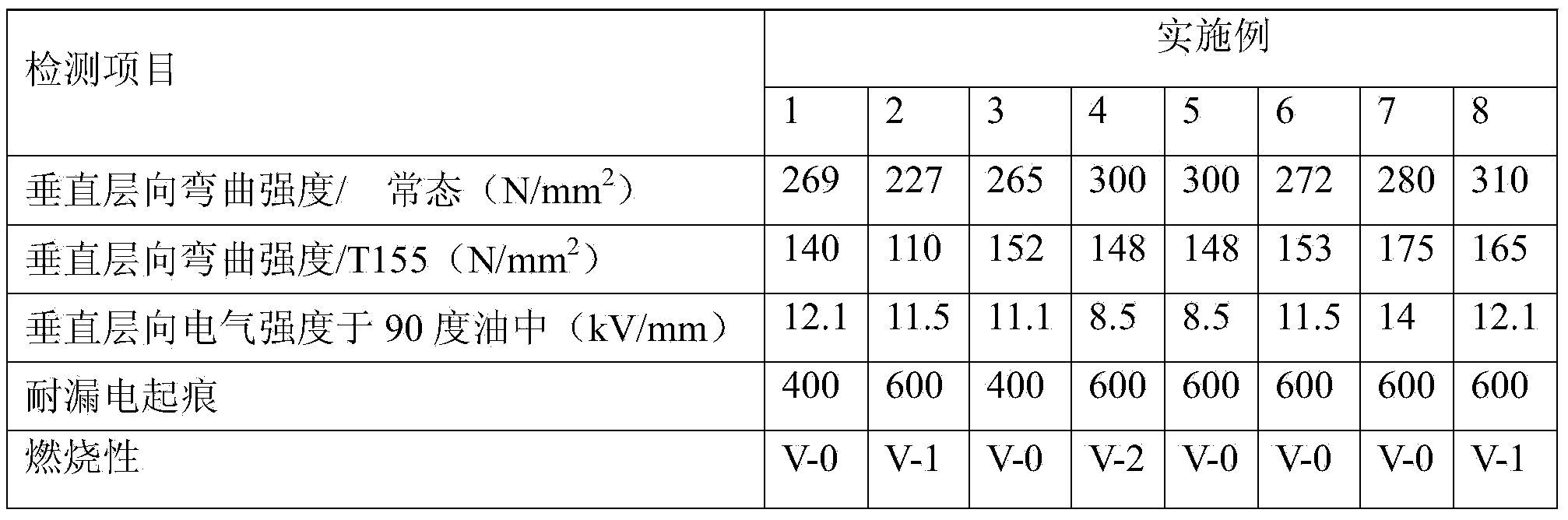

Examples

Embodiment 1

[0020] First, put 70 parts of novolak epoxy vinyl ester resin and 30 parts of polystyrene type low-shrinkage agent into the mixing tank according to the weight fraction ratio, and stir evenly, and add 5 parts of styrene, tert-butyl peroxide in turn under the condition of stirring. 1.0 parts of oxidized-2-ethylhexanoate, 1.5 parts of p-benzoquinone, 5 parts of zinc stearate, 20 parts of triethyl phosphate, stirred for 5 minutes until uniformly mixed, then added 140 parts of calcium carbonate and increased the stirring speed, Disperse at high speed for 10 minutes, then compound with 140 parts of glass fiber, and then cure in a drying room at 40°C for 72 hours at low temperature. Laminate according to the thickness after curing, and cure in a high-temperature mold at a temperature of 130°C for 8 minutes to obtain a halogen-free flame-retardant high-heat-resistant unsaturated polyester glass fiber composite material.

Embodiment 2

[0022] First, put 80 parts of bisphenol A type epoxy vinyl ester resin and 20 parts of polyvinyl acetate type low shrinkage agent into the mixing tank and stir evenly according to the weight fraction ratio, and add 5 parts of styrene, tert- 1.5 parts of butyl peroxy-2-ethylhexanoate, 1.8 parts of p-benzoquinone, 5 parts of zinc stearate, 10 parts of melamine, stirred for 5 minutes until uniformly mixed, then added 120 parts of calcium carbonate and increased the stirring speed, Disperse at high speed for 10 minutes, then compound with 140 parts of glass fiber, and then cure in a drying room at 40°C for 48 hours at low temperature. Laminate according to the thickness after curing, and cure in a high-temperature mold at a temperature of 130°C for 8 minutes to obtain a halogen-free flame-retardant high-heat-resistant unsaturated polyester glass fiber composite material.

Embodiment 3

[0024] First, put 85 parts of isophthalic unsaturated polyester and 15 parts of polyethylene terephthalate low-shrinkage agent into the mixing tank according to the weight fraction ratio, and stir evenly, and add 5 parts of styrene in turn under the condition of stirring , 2 parts of tert-butyl peroxy-2-ethylhexanoate, 3 parts of p-benzoquinone, 5 parts of zinc stearate, 20 parts of triethyl phosphate, stir for 5 minutes until mixed evenly, then add 160 parts of calcium carbonate And increase the stirring speed, disperse at a high speed for 10 minutes, and then compound with 140 parts of glass fibers, and then undergo low-temperature aging at 40°C in a drying room for 24 hours. Laminate according to the thickness after curing, and cure in a high-temperature mold at a temperature of 140°C for 5 minutes to obtain a halogen-free flame-retardant high-heat-resistant unsaturated polyester glass fiber composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com