Method for water treatment through permanganate homogeneous catalytic oxidation

A permanganate, homogeneous catalysis technology, applied in oxidation water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. Safe and convenient storage, good oxidation effect, and the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

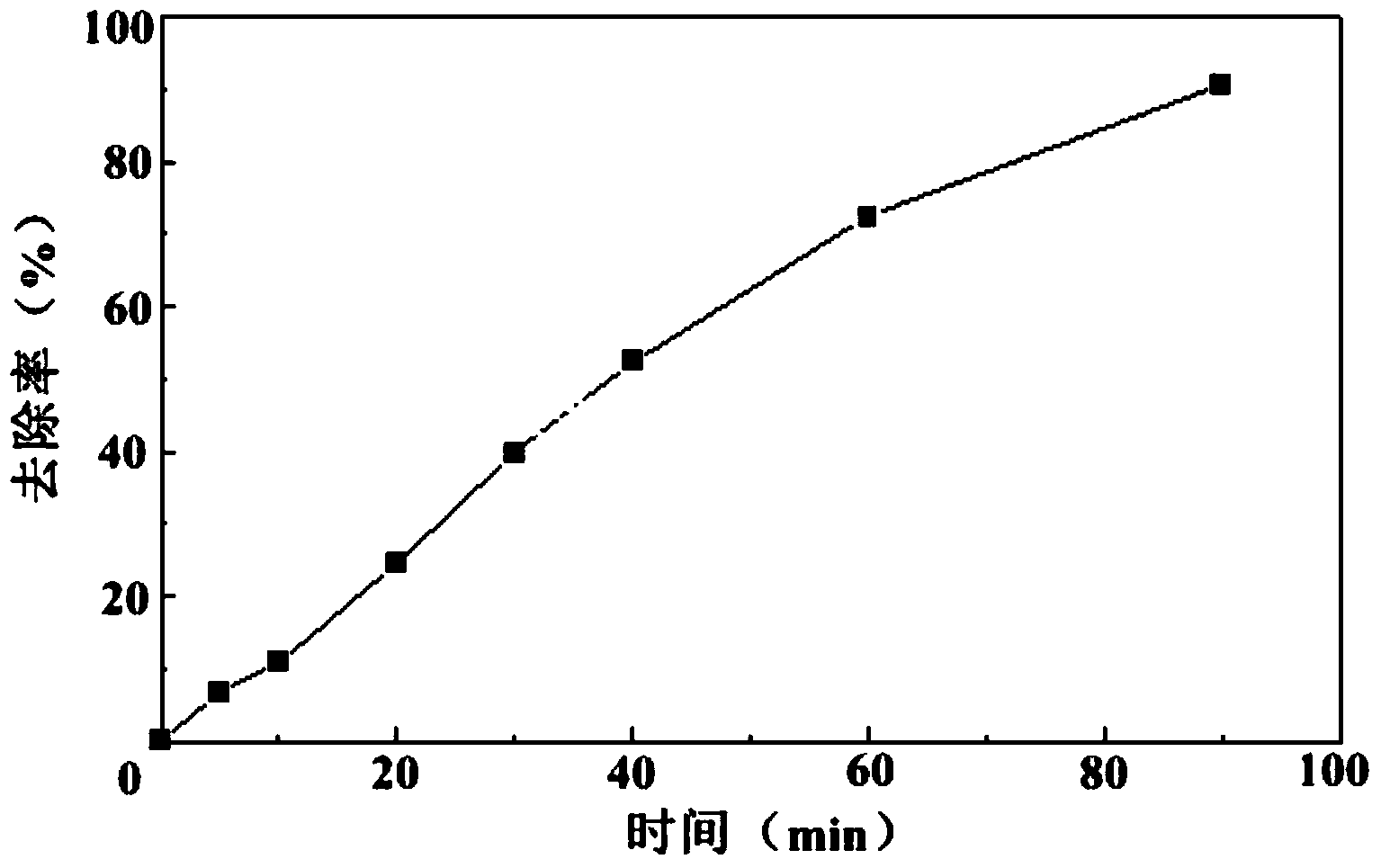

Image

Examples

specific Embodiment approach 1

[0014] Specific embodiment one: In this embodiment, a method for permanganate homogeneous catalytic oxidation water treatment is carried out according to the following steps:

[0015] 1. Add surfactant and permanganate to the raw water containing organic pollutants, stir and dissolve to obtain a mixed solution; the dosage of permanganate is 0.01mg to 500mg of permanganate per liter of water; The mass ratio of the surfactant to the permanganate is (0.5-500): 1, the permanganate is potassium permanganate or sodium permanganate; the surfactant is an anionic surfactant , cationic surfactants, zwitterionic surfactants, nonionic surfactants, fluorine-containing surfactants, silicon-containing surfactants, boron-containing surfactants, lignosulfonates, and crown ether surfactants A mixture of one or several combinations; when the surfactant is a mixture, each component in the mixture is mixed in any proportion before;

[0016] 2. Stir the mixed solution obtained in step 1, the stirr...

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment differs from Embodiment 1 in that the organic pollutant in the raw water containing organic pollutants described in step 1 is phenol. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the anionic surfactant described in step one is sodium stearate, potassium laurate, sodium dodecylbenzenesulfonate, fatty acid methyl Esters α-sulfonate sodium, succinate sulfonate, 1,2-di-n-butylnaphthalene-6-sodium sulfonate, sodium methylene bis-naphthalene sulfonate, sodium lauryl sulfate, lauryl polycyclo Sodium oxyethylene ether sulfate, sodium lauryl polyoxyethylene ether phosphate or sulfated castor oil, the cationic surfactant described in step 1 is dodecyl dimethyl benzyl ammonium bromide, diethyl Benzyl-β-octadecenamide ethylammonium chloride or cetyltrimethylammonium bromide, the zwitterionic surfactant described in step 1 is sodium lauryl carboxymethyl imidazoline acetic acid Salt, lauryl betaine, lecithin, amine oxide, carboxylic acid type β-alanine or N-aminoglycine, the nonionic surfactant described in step 1 is fatty alcohol polyethylene oxide ether...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com