Silver conductive slurry used for solar cell, solar cell, and solar cell preparation method

A technology for solar cells and solar cells, applied in the field of solar cells, can solve the problems of low density of grid lines in the seed layer, increased shading area, decreased short-circuit current of cells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

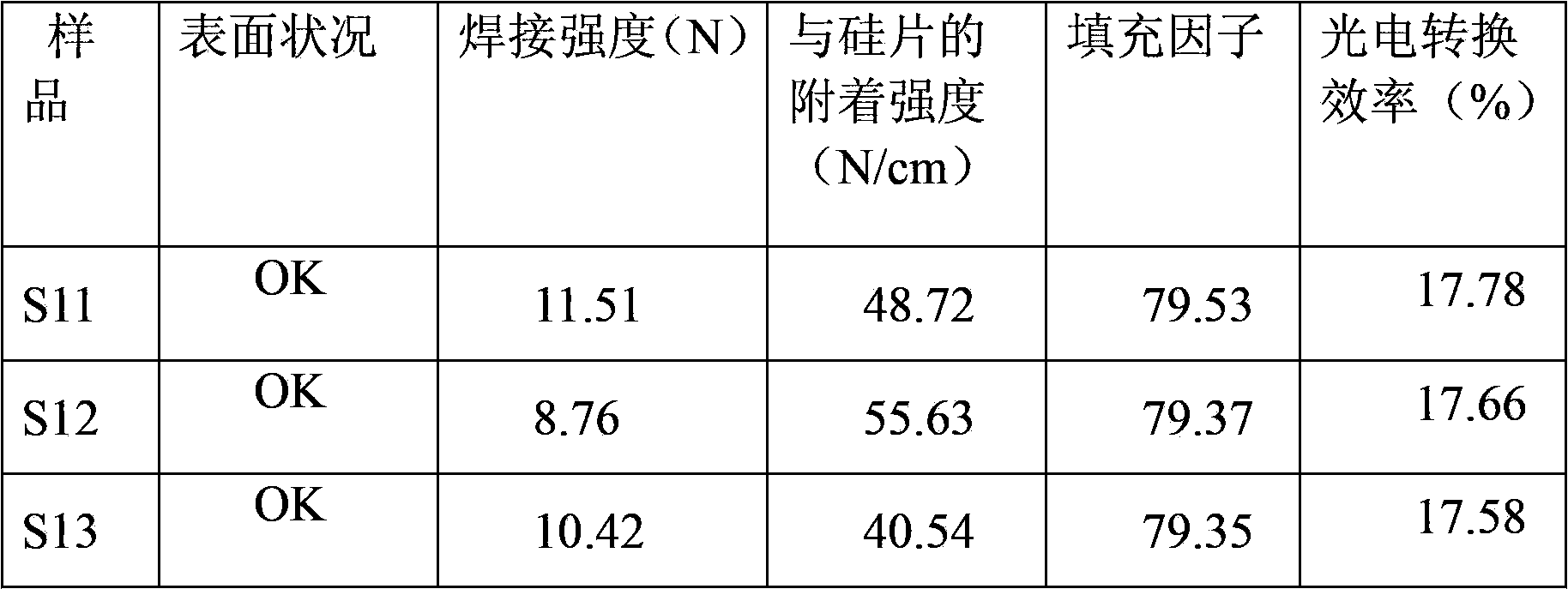

Examples

preparation example Construction

[0020] In the preparation method of the above-mentioned silver conductive paste of the present invention, the conductive phase, conductive metal powder, inorganic binder and organic vehicle can be mixed and ground to a certain fineness. Wherein, the mixing method of the present invention is not limited, and is designed according to actual conditions. For example, it can be:

[0021] (1) Dissolve the thickener such as ethyl cellulose, additives such as lubricants and thixotropic agents in terpineol or other mixed solvents composed of the above-mentioned organic solvents, and make the ethyl cellulose The cellulose is fully dissolved and stirred evenly to obtain a transparent organic carrier.

[0022] (2) Put the organic carrier in the stainless steel tank of the high-speed disperser, add glass powder and silver-silicon alloy powder while stirring, and stir well; add silver-silicon powder in several times, after adding all, stir at high speed; Use a three-roll mill to grind the...

Embodiment 1

[0035] This example is used to prepare silver conductive paste.

[0036] (1) Preparation of glass powder

[0037] Take 79wt% Bi 2 o 3 , 10wt% SiO 2 , 8wt% ZnO, 3wt% TiO 2 , use a V-type mixer to mix evenly, put it into a porcelain crucible, put it into a silicon carbide rod furnace, preheat it to 550°C, keep it warm for 0.5h, then raise it to 1250°C, melt it for 0.5h, water quench and filter, and the glass will be obtained Put the beads into the ball mill tank, control the mass ratio, zirconia ball: glass beads: deionized water = 4: 1: 0.7, tank speed 300 / min, ball mill for 7 hours, filter, dry, dry mill for 1 hour, and oxidize during dry milling The mass ratio of zirconium balls to glass beads is 1:2. Test the medium particle size D of the glass powder 50 0.65μm, softening point (T s ) at 510°C.

[0038] (2) Configuration of organic carrier

[0039] According to the mass ratio of lauryl alcohol ester: butyl carbitol: butyl carbitol acetate = 70:20:10, the organic sol...

Embodiment 2

[0043] Adopt the method identical with embodiment 1 to prepare silver conductive paste sample S2, difference is silver-silicon alloy powder, and silver element content is 95.00 ± 0.05wt% in the silver-silicon alloy powder, and the tap density of silver-silicon alloy powder is 4.98g / cm 3 , the viscosity of test sample S2 is 62.6 Pas.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com