Corynebacterium glutamicum engineering bacterium for highly producing succinic acid and building method thereof

A technology of Corynebacterium glutamicum and glutamic acid rod, which is applied in the field of microbial genetic engineering, can solve problems such as growth restriction, and achieve the effects of improving conversion rate, reducing production cost, and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

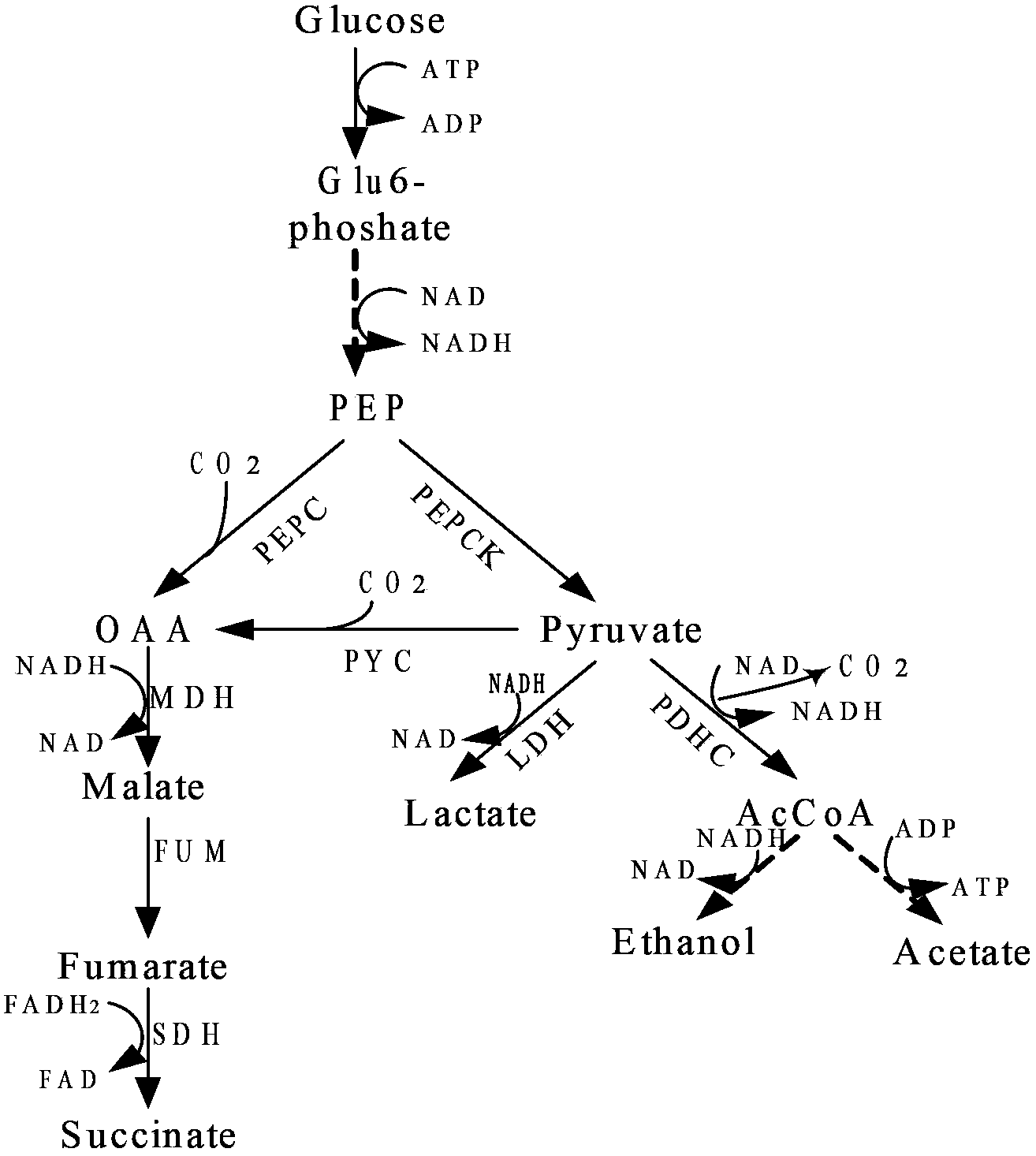

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Preparation and Transformation of Escherichia coli JM109 Competent in Example 1

[0058] ① Streak the bacterial solution frozen with 20% glycerol on the corresponding resistant LB plate, and culture it overnight in a 37°C incubator. base, cultivate overnight at 37°C on a shaker at 100r / min;

[0059] ②Transfer the overnight culture into 50mL / 500mL fresh LB liquid medium according to the inoculum amount of 1%, and culture it in a shaker flask at 37°C and 100r / min for about 1.5-2h. 600 About 0.6, ice bath 10min;

[0060] ③Centrifuge at 5,000r / min for 10min at 4°C, discard the supernatant, and collect the bacteria; resuspend the bacteria in 20ml of 100mmol / L CaCl 2 In the solution, ice-bath for 20 minutes; centrifuge at 5,000 r / min for 10 minutes at 4°C, discard the supernatant, and collect the bacteria;

[0061] ⑤Take 1mL100mmol / L of CaCl 2 The solution (containing 15% glycerol) is slowly blown and sucked to gently suspend the bacteria;

[0062] ⑥ Dispense 70 μL into ...

example 2

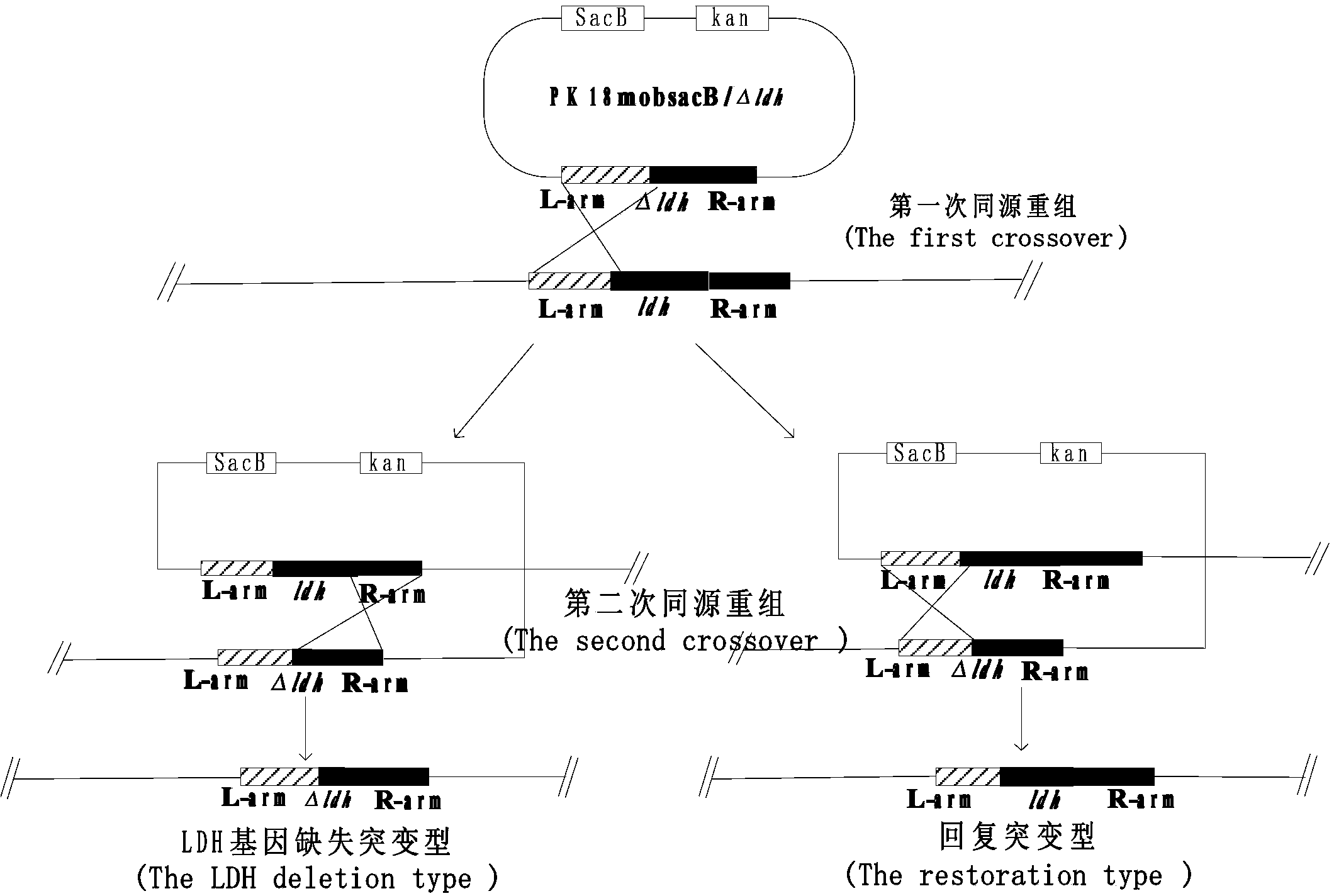

[0067] Construction of Example 2 Gene Deletion Plasmid and Gene Deletion

[0068] The left and right homology arms used for homologous recombination are sequentially connected to pk18mobsacB by enzyme-linking the ldh gene knockout plasmid. Process is as follows, by primer SEQIDNO:1, SEQ ID NO:2 with the genome of wild-type Corynebacterium glutamicum ATCC13032 as template, carry out routine PCR to obtain left homologous arm gene fragment (1175bp), the gene fragment obtained is purified with PCR product kit for purification. The pk18mobsacB plasmid and the purified gene fragment of the left homology arm were double-digested with EcoRI and SalI, the two were subjected to agarose gel electrophoresis, and the gene fragment was recovered with a gel recovery kit. The left homology arm was ligated to the plasmid with T4 ligase. In the same way, primers SEQ ID NO: 3 and SEQ ID NO: 4 use the genome of wild-type Corynebacterium glutamicum ATCC13032 as a template to carry out convention...

example 3

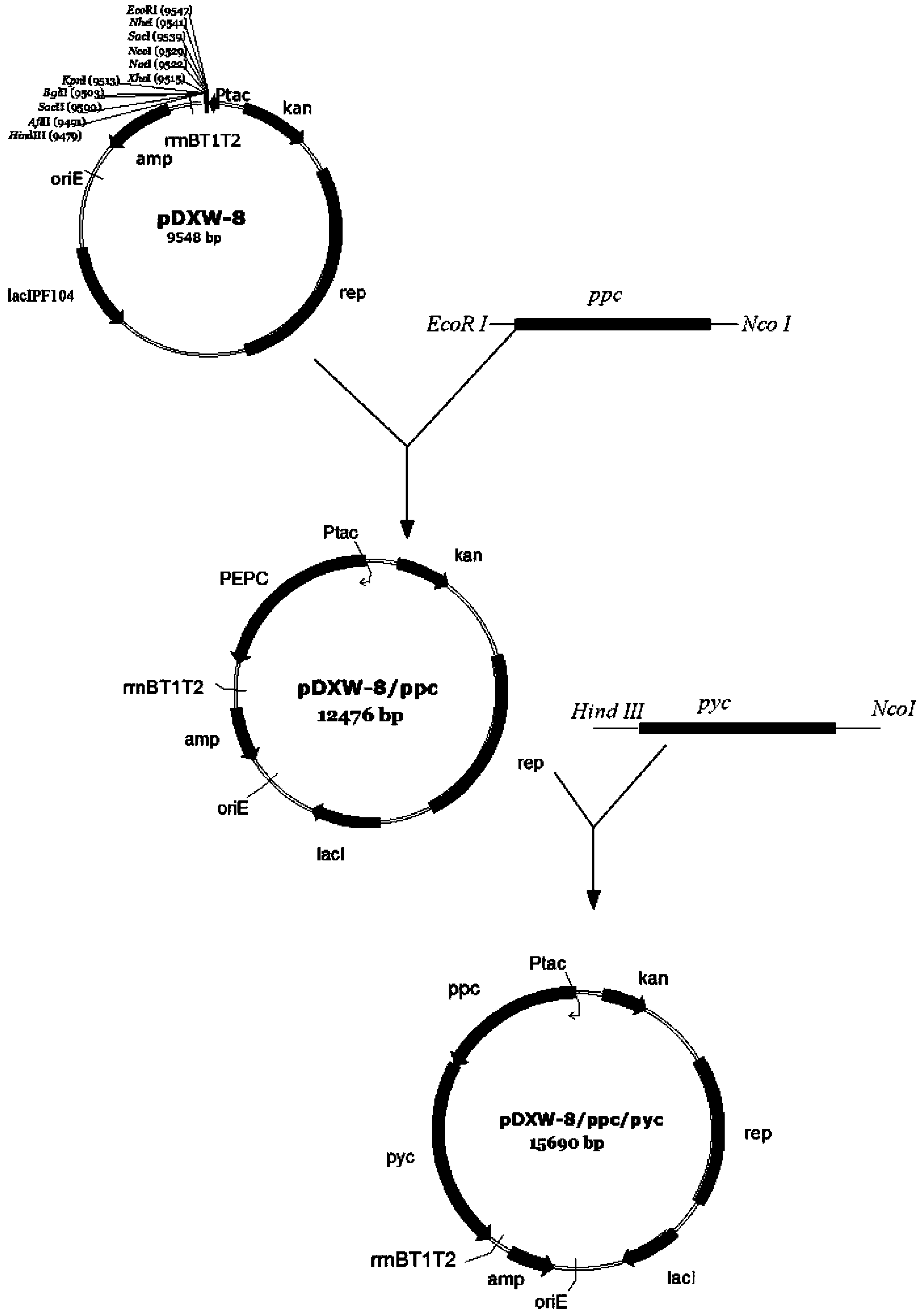

[0080] Construction of Example 3 Expression Plasmid pDXW--8 / ppc / pyc

[0081] Using SEQ ID NO: 5 and SEQ ID NO: 6 as primers and the genome of Corynebacterium glutamicum as a template, the gene was amplified by conventional PCR and then purified by a PCR purification kit. The purified gene fragment and plasmid pDXW-8 were double-digested with NcoI and HindIII, and the digested product was electrophoresed on 1% agarose gel, and the gene fragment and linearized plasmid fragment were recovered by tapping the gel. The purified fragments were enzyme-ligated, and the ligated product was directly transformed into Escherichia coli JM109 competent cells. Colony PCR was used to select Escherichia coli positive bacteria carrying the recombinant plasmid. The recombinant expression plasmid pDXW-8 / pyc was obtained by small extraction of the plasmid, using SEQ ID NO: 7 and SEQ ID NO: 8 as primers, and the high-lysine-producing Escherichia coli MG1655 genome as a template, after PCR amplifyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com