Method used for producing floss picks by wire groove sintering

A manufacturing process and technology of dental floss sticks, applied in the direction of dental floss, etc., can solve the problems of unstable installation, increased use cost, unreliable straightness and toughness, etc., to enhance stability and toughness, increase production capacity, extend The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

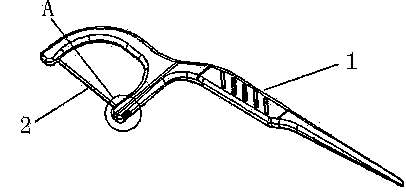

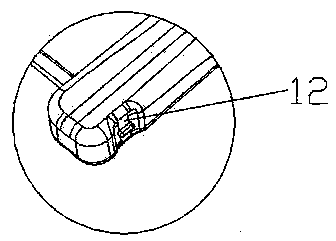

[0017] A manufacturing process of a dental floss stick produced by the groove sintering method, the dental floss stick includes a stick body 1 and a dental floss 2, and the stick body 1 includes a head, a grip and a tail, wherein the head The head is bow-shaped, and the two ends of the head are the clamping ends of the dental floss 2. The dental floss 2 is pre-embedded in the clamping end of the rod body 1 mold through a wire pulling device, and is integrally formed with the rod body 1 through injection molding; its production method is mainly It includes the following steps: (1) Preparation of raw materials: use ABS or HIPS plastic material and toner as the main molding raw materials for dental floss stick body 1, put them in a mixer and stir evenly to be injection molded; use nylon thread or polyester or PTFE or Yarn or cotton thread or black bamboo charcoal thread is used as the main raw material of dental floss 2; (2) Formed dental floss stick: first and then put the main m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com