Preparation method of energetic fullerene thin film in petal-shaped microstructure

A microscopic morphology, fullerene technology, applied in nanotechnology, organic chemistry, etc., can solve the problems of weakening the photoelectric properties of fullerene, high fullerene content, small specific surface area, etc., and achieve a simple, fast, high-rich preparation method The effect of the content of strene and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In a 100 ml single-necked volumetric flask, add 0.0582 g of C 60 , 0.0110 grams of p-nitrobenzaldehyde, 0.0381 grams of sarcosine and 30 milliliters of toluene, refluxed at 115 ° C for 5 hours under the protection of nitrogen, the color of the solution changed from purple to brown. Concentrate with a vacuum rotary evaporator and then purify by silica gel column chromatography, the eluent is toluene and n-hexane (volume ratio 20:1). The resulting product was recrystallized from chloroform and isopropanol (volume ratio 25:3) to obtain nitrophenyl-substituted fullerene derivatives. Characterized by MALDI-TOF-MS, m / z calcd 897.8; found 896.8 (100%).

Embodiment 2

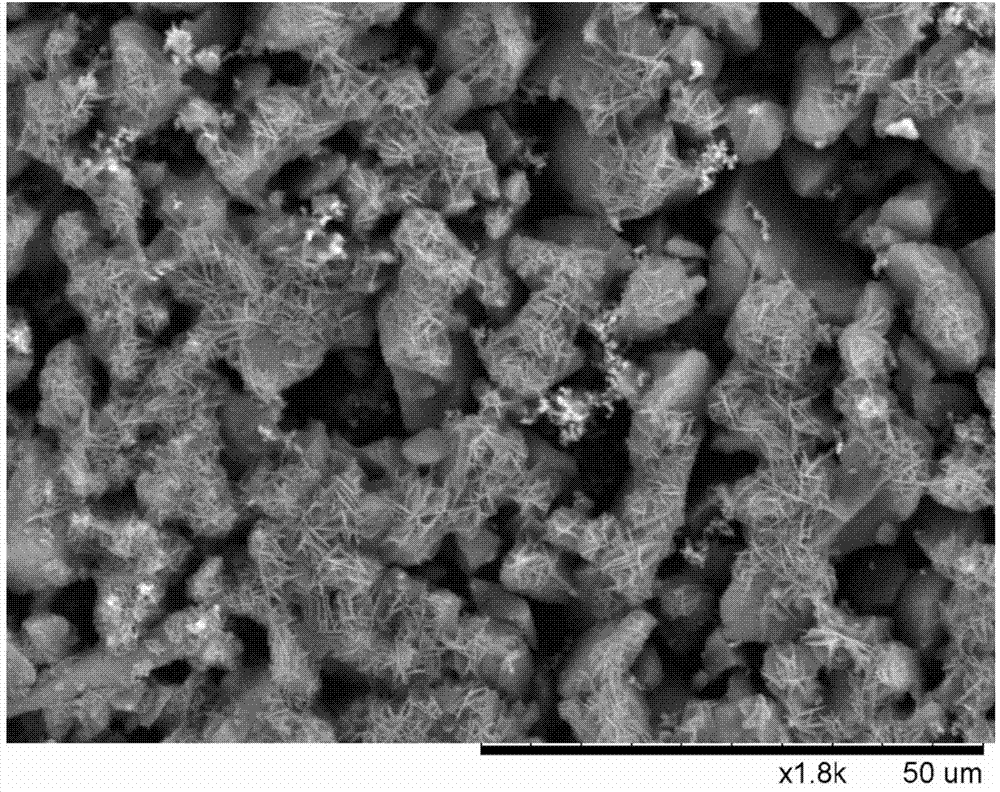

[0038] Self-assembly of fullerene derivatives on solid substrates and preparation of energetic fullerene films with petal-like microscopic morphology.

[0039] Cut the solid substrate into square pieces of about 0.25 cm2 with a glass knife (for monocrystalline silicon) or scissors (for nylon, ginkgo leaves and camphor leaves), rinse the surface with acetone, and dry naturally; take out 20 Microliter 1 mg / ml fullerene derivative in chloroform-ethanol (volume ratio 10:1) solution, or 20 microliter 1 mg / ml fullerene derivative in chloroform-n-hexane (volume ratio 10:1) solution , were directly dropped on a clean solid substrate, and evaporated to dryness naturally; the substrate with the fullerene self-assembled structure was sprayed with gold for 20 seconds, and the fullerene film was observed by Hitachi TM-1000 scanning electron microscope petal-like microstructure.

Embodiment 3

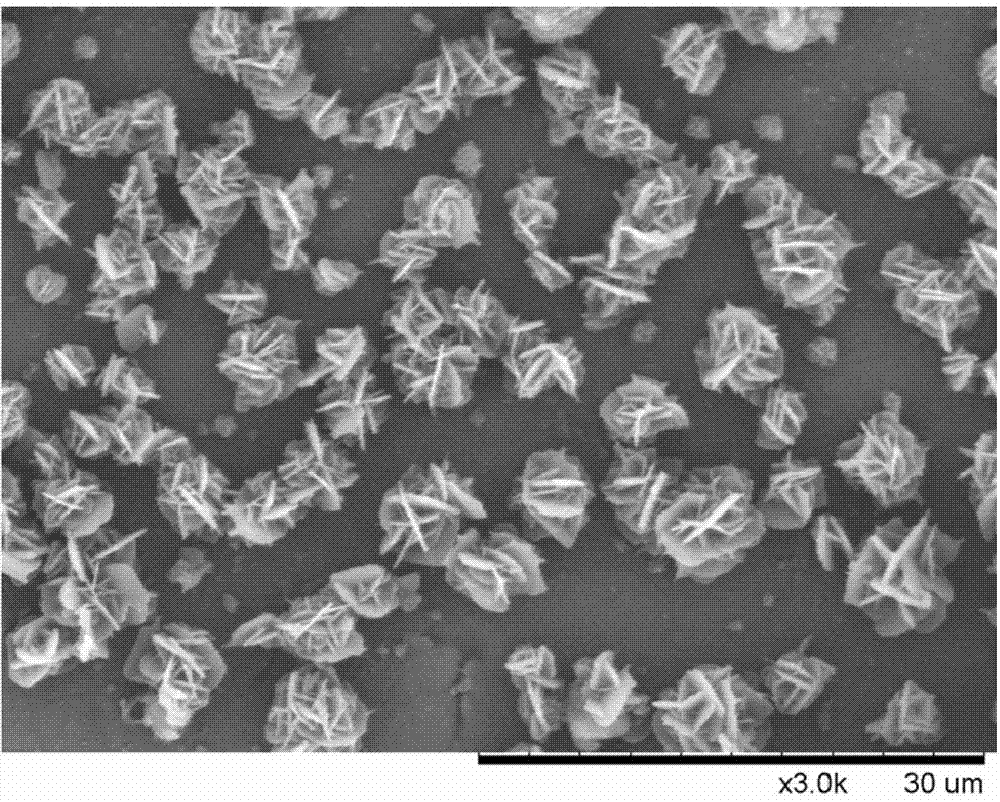

[0041] Preparation of energetic fullerene films with petal-like microscopic morphology on single crystal silicon substrates.

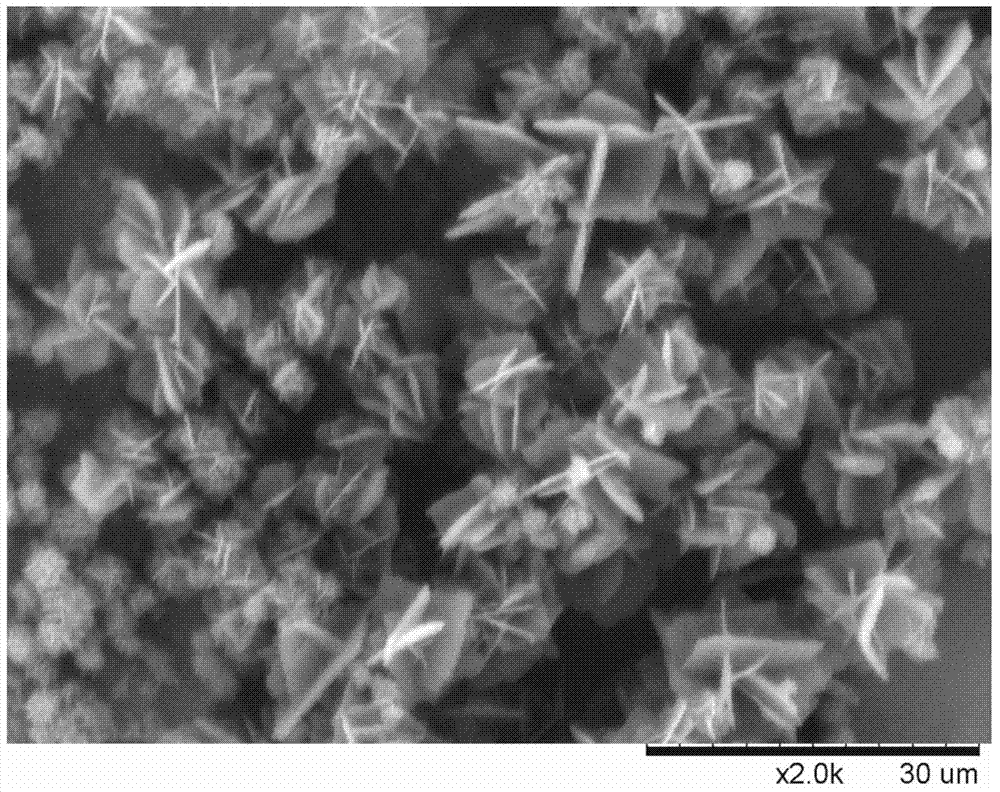

[0042] Cut the solid substrate monocrystalline silicon into square pieces of about 0.25 cm2 with a glass knife, rinse the surface with acetone, and let it dry naturally; use a pipette gun to take out 20 μl of 1 mg / ml fullerene derivative in chloroform-ethanol ( 10:1 by volume) solution, or 20 microliters of 1 mg / ml fullerene derivative in chloroform-n-hexane (10:1 by volume) solution, were directly dropped on the clean solid substrate single crystal silicon, and naturally Evaporate until dry; spray gold on the substrate with fullerene self-assembled structure for 20 seconds, and observe with a Hitachi TM-1000 scanning electron microscope, you can see the petal-shaped microscopic morphology of the fullerene film material.

[0043] The scanning electron micrograph of the petal-shaped microscopic morphology of the fullerene film obtained from the chlorofo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com