Sheet bonding method in substrate thinning technique

A substrate and process technology, which is applied in the field of microwave power field effect transistor and integrated circuit technology, to achieve the effects of avoiding mutual dissolution, increasing process complexity, improving process efficiency and process yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

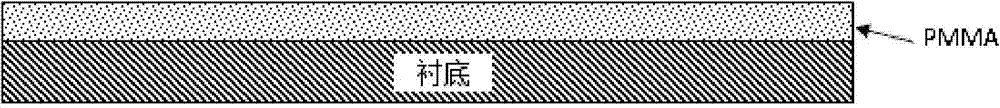

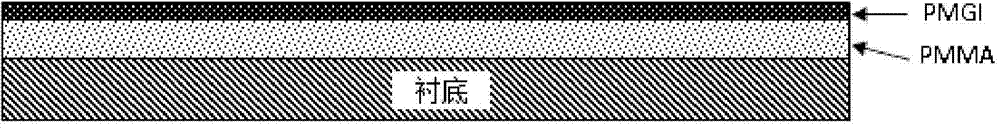

[0029] The chip bonding method in the substrate thinning process provided by the present invention is to use the PMMA950-A11 / PMGI / high temperature wax structure, insert the PMGI layer between the PMMA950-A11 electron beam photoresist and the high temperature wax, and utilize the intrinsic properties of PMGI Properties, prevent the miscibility of two organic compounds from occurring. In this way, after the thinning process and other backside processes are completed, the substrate and the wafer holder can be successfully separated by the degumming process, which greatly shortens the process time and avoids the generation of insoluble organic matter.

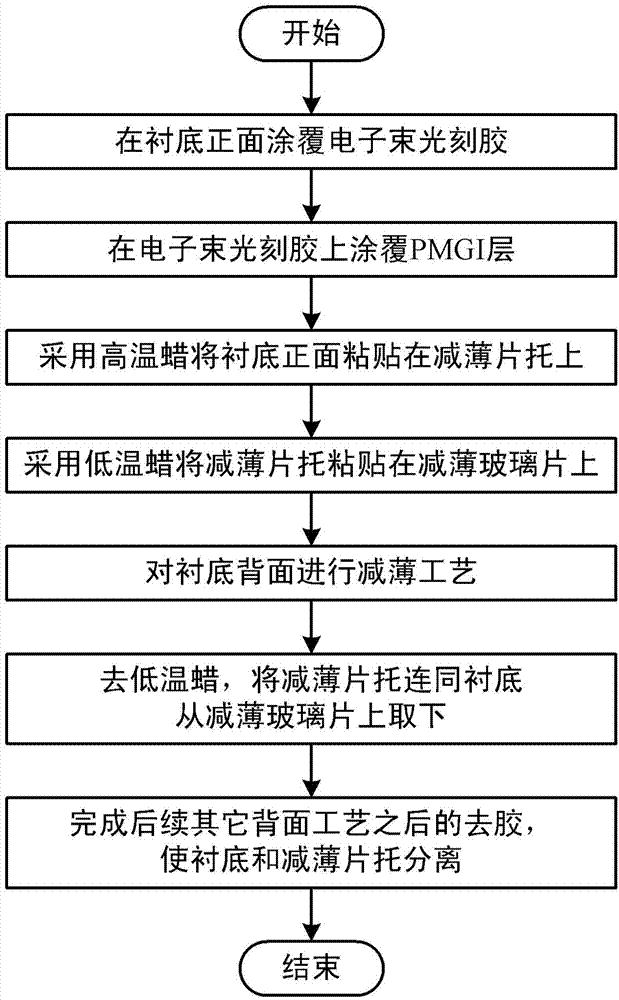

[0030] Such as figure 1 as shown, figure 1 It is a flow chart of the ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com