Method for manufacturing Pt resistor temperature sensor

A manufacturing method and technology of resistance temperature, applied to thermometers, thermometers using directly heat-sensitive electric/magnetic elements, instruments, etc., can solve the problems of slow ion beam etching rate, difficulty in reducing preparation efficiency and processing cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

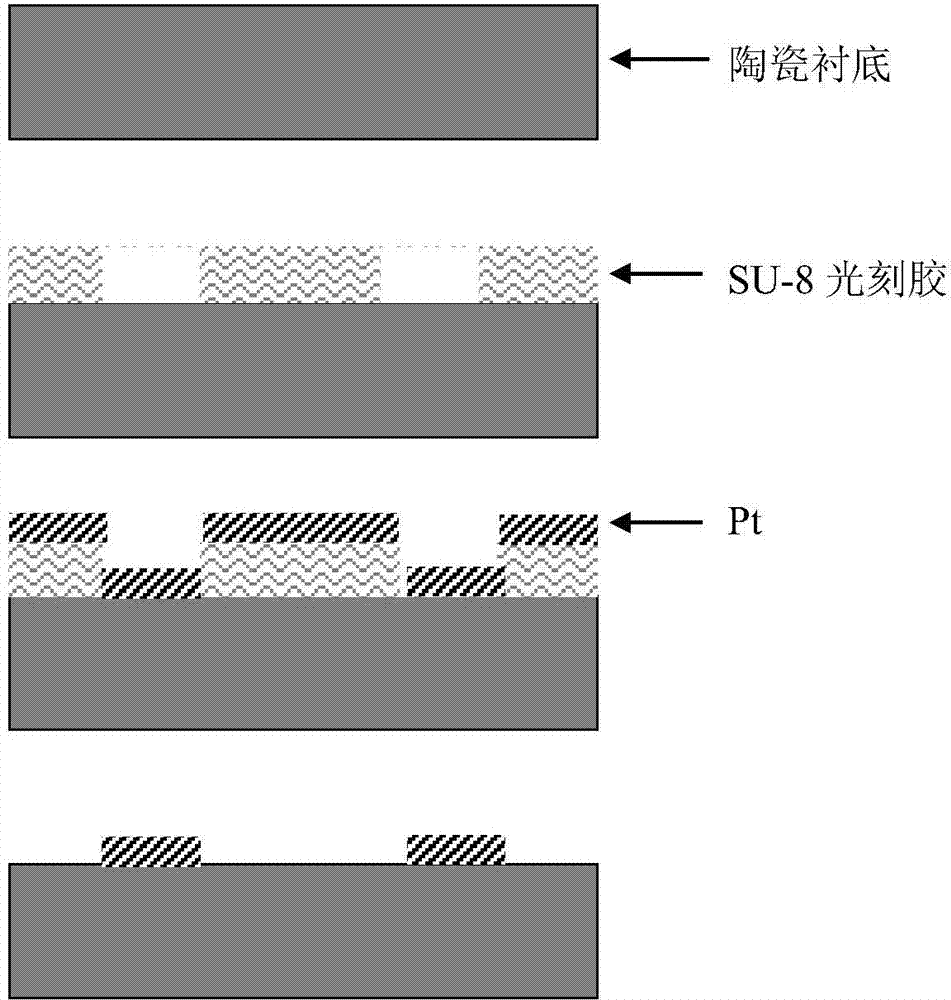

[0018] A method for manufacturing a Pt resistance temperature sensor, comprising the following steps:

[0019] (1) Clean a ceramic substrate of a certain size (such as 3 inches) with absolute ethanol (MOS grade) and deionized water in sequence, then dry it, and then evaporate HMDS (a coupling agent) on the ceramic substrate.

[0020] (2) Apply SU-82025 (a type of SU-8 glue) photoresist to the processed ceramic substrate by spin coating method, with a thickness of 5 μm to 10 μm.

[0021] (3) Pre-bake the photoresist on a hot plate under the conditions of 65°C / 3min and 95°C / 5min.

[0022] (4) Expose in a lithography machine with a UV light source, and the exposure meter is 150mJ / cm 2 .

[0023] (5) After-baking on a hot plate, the conditions are 65°C / 1min, 95°C / 5min.

[0024] (6) Develop with SU-8 special developer, and use O 2 Plasma to remove the bottom film.

[0025] (7) Put the photolithographically completed ceramic substrate into a magnetron multi-target sputtering ma...

Embodiment 2

[0029] (1) Use a ceramic substrate of a certain size (such as 3 inches) with H 2 SO 4 +H 2 o 2 , deionized water, and then dried, and then evaporated HMDS (a coupling agent) on the ceramic substrate.

[0030] (2) Apply SU-82025 (a type of SU-8 glue) photoresist to the processed ceramic substrate by spraying glue, with a thickness of 5 μm to 10 μm.

[0031] (3) Pre-bake the photoresist on a hot plate under the conditions of 65°C / 3min and 95°C / 5min.

[0032] (4) Expose in a lithography machine with a UV light source, and the exposure meter is 150mJ / cm 2 .

[0033] (5) After-baking on a hot plate, the conditions are 65°C / 1min, 95°C / 5min.

[0034] (6) Develop with SU-8 special developer, and use O 2 Plasma to remove the bottom film.

[0035] (7) Put the electron beam evaporation equipment above to obtain the ceramic substrate Pt metal with a thickness of about 2 μm.

[0036] (8) Put the ceramic substrate obtained above into a NaOH salt bath furnace at high temperature to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com