Method for recovering metal materials in waste ternary power batteries

A metal material and recovery method technology, applied in the field of metal material recovery, can solve the problems of single product function, lithium cannot be precipitated, and affect the effect of lithium precipitation, etc., to achieve a variety of products, which is beneficial to sewage treatment and environmental protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

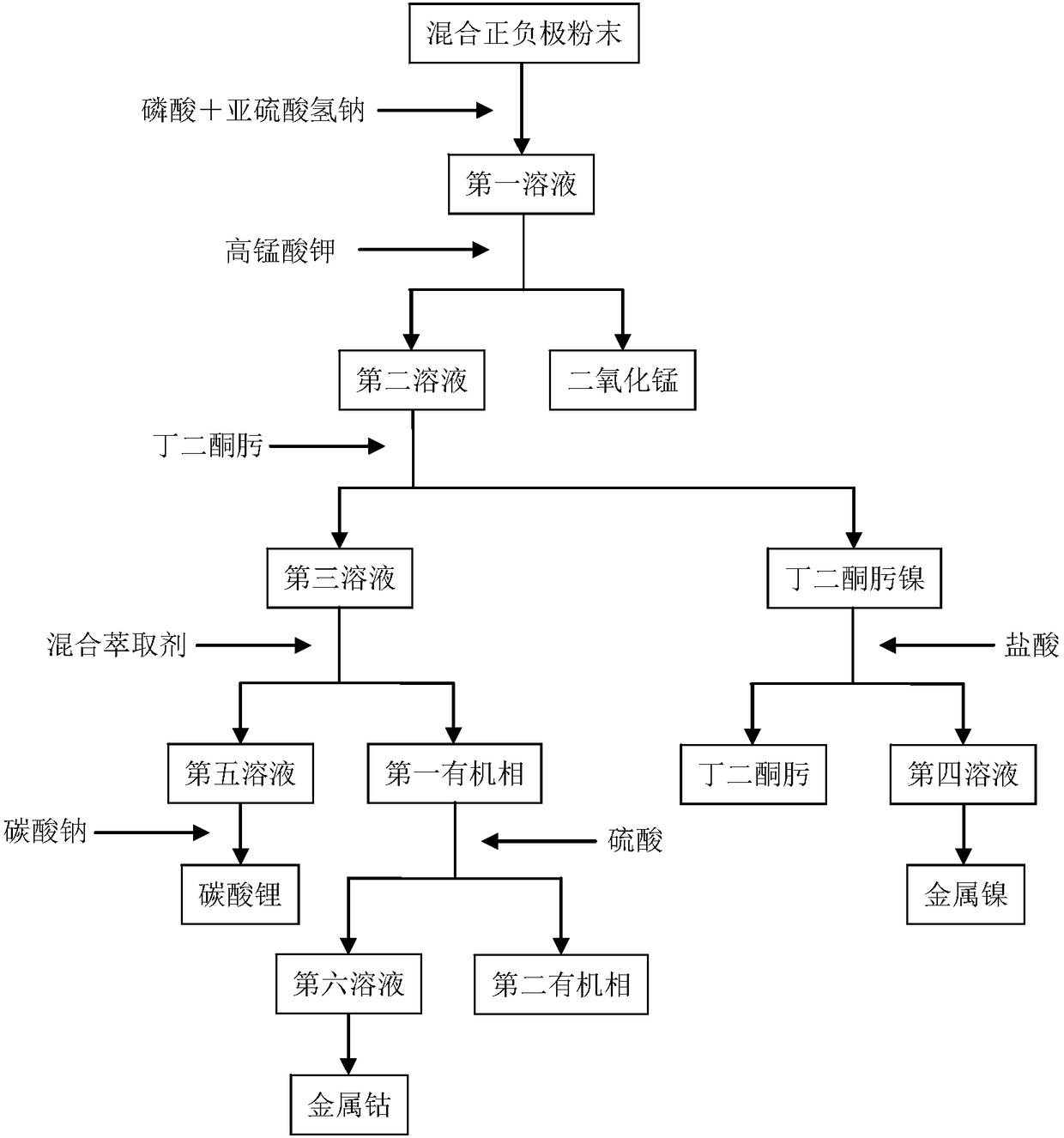

Image

Examples

Embodiment 1

[0040] (1) Metal ion leaching:

[0041] Weigh 100g of the positive and negative electrode mixed powder of the waste nickel-cobalt-manganese ternary power battery, add phosphoric acid solution and sodium bisulfite solution in turn, so that the ratio of the volume of the liquid in the reaction system to the mass of the solid powder is 10:1, and the unit is mL / g, that is, the added liquid volume is 1000mL, the molar concentration of phosphoric acid in the reaction solution is 1.5mol / L, and the molar concentration of sodium bisulfite is 0.05mol / L, react at 80°C for 4 hours, and filter to obtain the A solution, the first solution contains manganese ions, nickel ions, cobalt ions, lithium ions;

[0042] (2) Recovery of manganese:

[0043] Add potassium permanganate solution in above-mentioned first solution, carry out reaction, make the molar concentration ratio of potassium permanganate and manganese ion in the reaction solution be 1:1, the pH value of reaction solution is 1, filt...

Embodiment 2

[0051] (1) Metal ion leaching:

[0052] Weigh 100g of the positive and negative electrode mixed powder of waste nickel-cobalt-manganese ternary power battery, add phosphoric acid solution and sodium bisulfite solution in turn, make the ratio of the volume of the liquid in the reaction system to the mass of the solid powder be 20:1, the unit is mL / g, that is, the added liquid volume is 2000mL, the molar concentration of phosphoric acid in the reaction solution is 2.5mol / L, and the molar concentration of sodium bisulfite is 0.075mol / L, react at 110°C for 6 hours, and filter to obtain the A solution, the first solution contains manganese ions, nickel ions, cobalt ions and lithium ions;

[0053] (2) Recovery of manganese:

[0054] Add potassium permanganate solution in above-mentioned first solution, carry out reaction, make the molar concentration ratio of manganese ion and potassium permanganate in the reaction solution be 1.5:1, the pH value of reaction solution is 2, filter a...

Embodiment 3

[0062] (1) Metal ion leaching:

[0063] Weigh 100g of the positive and negative electrode mixed powder of the waste nickel-cobalt-manganese ternary power battery, add phosphoric acid solution and sodium bisulfite solution in turn, so that the ratio of the volume of the liquid in the reaction system to the mass of the solid powder is 30:1, and the unit is mL / g, that is, the added liquid volume is 3000mL, the molar concentration of phosphoric acid in the reaction solution is 4mol / L, and the molar concentration of sodium bisulfite is 0.1mol / L, react at 130°C for 8 hours, and filter to obtain the first Solution, the first solution contains manganese ions, nickel ions, cobalt ions and lithium ions;

[0064] (2) Recovery of manganese:

[0065] Add potassium permanganate solution in above-mentioned first solution, carry out reaction, make the molar concentration ratio of potassium permanganate and manganese ion in the reaction solution be 2:1, the pH value of reaction solution is 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com