A high impedance composite film

A composite film and high-impedance technology, which is applied in the field of space liquid medium storage, can solve the problems of astronauts' health impact, poor air tightness, and inability to stop, and achieve excellent chemical resistance stability, super water and gas resistance, and use wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

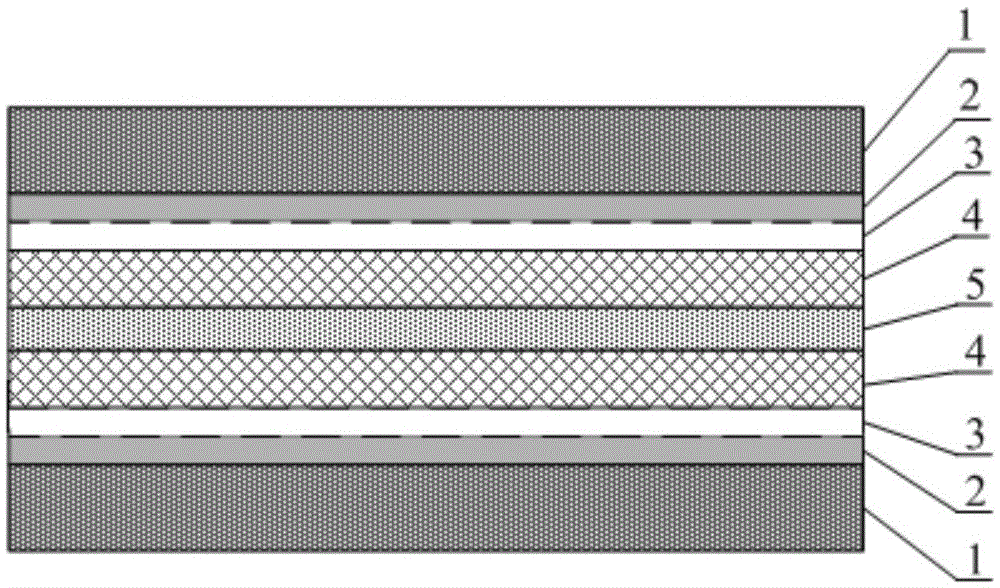

Embodiment 1

[0021] Example 1: The thickness ratio of each film material is 50% of metallocene polyethylene, 10% of polyethylene adhesive, 10% of adhesive, 20% of nylon, and 10% of ethylene-vinyl alcohol copolymer. Layered high-impedance composite film composite film with a thickness of 0.15mm. It has the characteristics of high water barrier, gas barrier and high chemical resistance, and its compatibility with various media is tested well. Compatibility test results with astronauts’ drinking water showed that the silver content did not change much after storage for 150 days, all around 0.20mg / L; while the TOC (total organic carbon content) increased slowly with time, and the TOC was less than 20mg / L at 180 days. L; The content of caprolactam shows an increasing trend, and its content is only 2.29mg / L at 150 days, which is far below the requirement of less than 15mg / L. Mechanical properties test, longitudinal and transverse tensile strength, longitudinal and transverse tensile strain at br...

Embodiment 2

[0022] Example 2: Nine layers made of each film material with a thickness ratio of 40% metallocene polyethylene, 15% polyethylene adhesive, adhesive 5, nylon 25%, and ethylene-vinyl alcohol copolymer 15% High-impedance composite membrane composite membrane with a thickness of 0.1mm. The nine-layer high-impedance composite film made from this ratio has good mechanical properties, but its chemical stability is worse than that of Example 1, and its water and gas barrier properties are equivalent to those of Example 1.

Embodiment 3

[0023] Example 3: Nine layers made of the thickness ratio of each film material: 60% of metallocene polyethylene, 5% of polyethylene adhesive, 15% of adhesive, 15% of nylon, and 5% of ethylene-vinyl alcohol copolymer High-impedance composite membrane composite membrane with a thickness of 0.3mm. The nine-layer high-impedance composite film made from this ratio has good chemical resistance stability, but its mechanical properties are worse than that of Example 1, and its water and gas barrier properties are better than those of Example 1 and Example 2.

[0024] The new nine-layer high-impedance composite film has good thermoplasticity, and the film can be made into a container for liquid by heat-sealing technology to achieve the purpose of storing and transporting space station water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com