Preparation method for bismuth vanadate composite photocatalyst loaded with strontium ferrite

The technology of strontium ferrite and bismuth vanadate is applied in the field of preparation of bismuth vanadate composite photocatalyst, can solve the problems of low photocatalytic efficiency and recovery rate, etc., and achieve the effects of enriching categories, reducing costs, and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

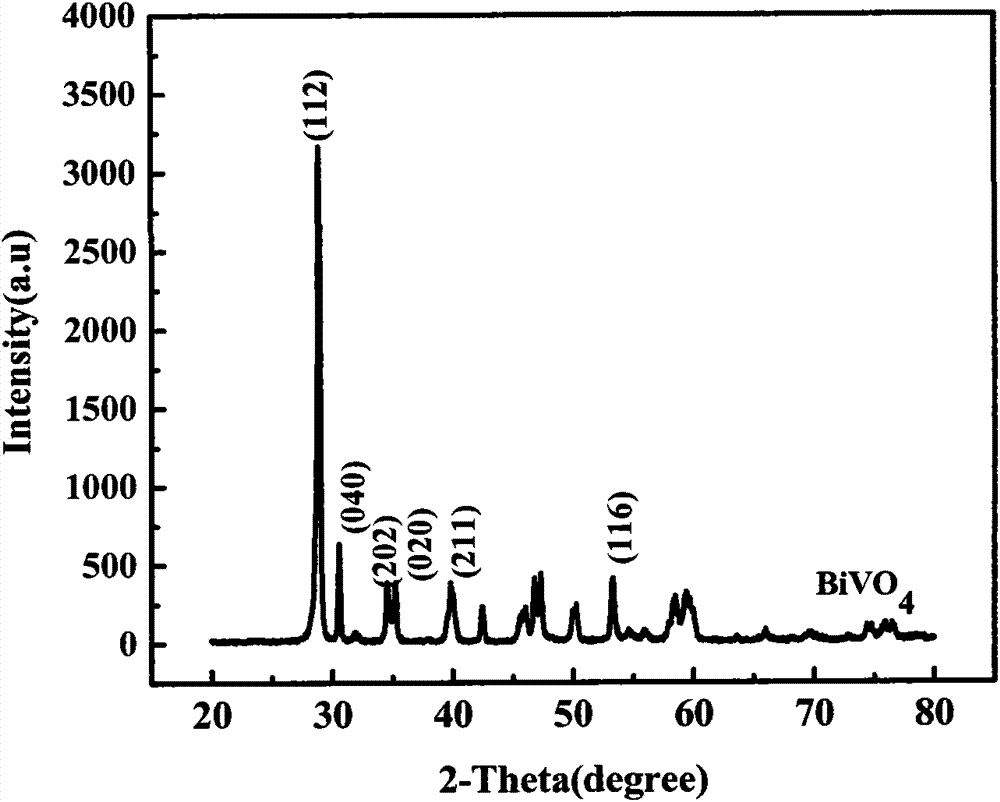

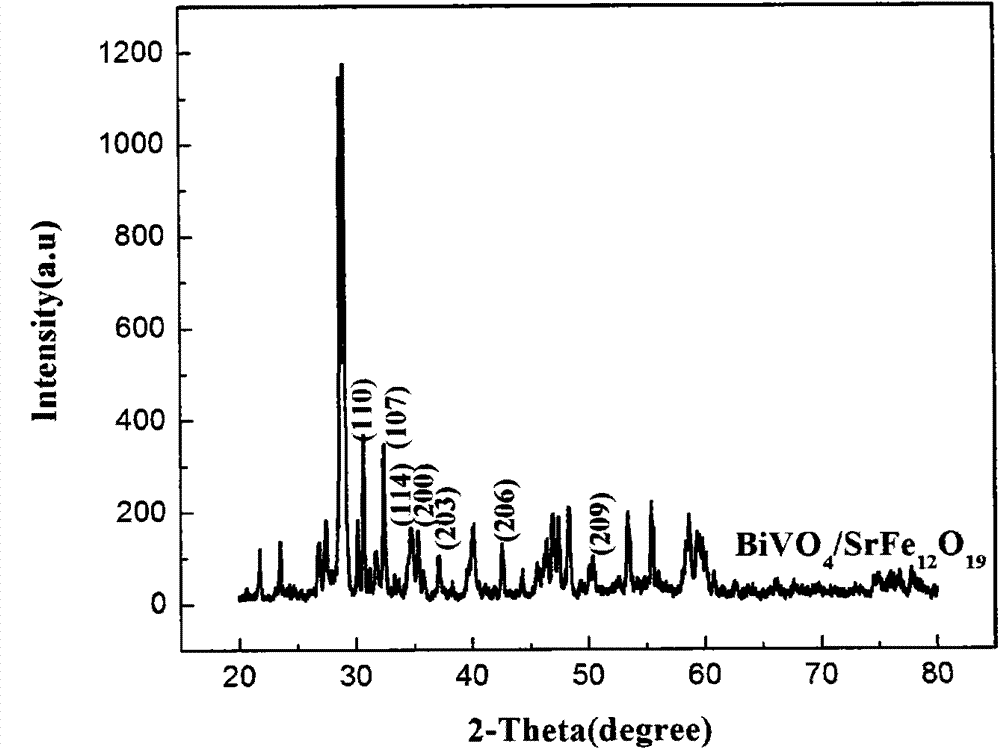

Image

Examples

Embodiment 1

[0022] A kind of preparation method of the bismuth vanadate composite photocatalyst supported by strontium ferrite, its concrete steps are as follows:

[0023] (1) Preparation of bismuth vanadate solution

[0024] With Bi(NO 3 ) 3 ·5H 2 O and NH 4 VO 3 As raw material, tartaric acid (C 4 h 6 o 6 ) as complexing agent, using nitric acid and water as solvent, according to Bi(NO 3 ) 3 ·5H 2 The amount of species of O (mol): NH 4 VO 3 The amount of substance (mol): C 4 h 6 o 6 The amount of substance (mol) is a ratio of 1:1:2, Bi(NO 3 )3 ·5H 2 O and C 4 h 6 o 6 Add it into a reaction vessel filled with 2mol / L nitric acid solution and stir at constant temperature for 30min, then adjust the pH to 7.5 with ammonia water to obtain solution A, and mix NH 4 VO 3 Add it into hot water at 70°C and dissolve to obtain solution B. Mix the two solutions A and B, and stir at constant temperature for 30 minutes to obtain a bismuth vanadate solution.

[0025] (2) Preparati...

Embodiment 2

[0030] A kind of preparation method of the bismuth vanadate composite photocatalyst supported by strontium ferrite, with embodiment 1, wherein:

[0031] In step (1), with Bi(NO 3 ) 3 ·5H 2 The amount of species of O (mol): NH 4 VO 3 The amount of substance (mol): C 4 h 6 o 6 The amount of substance (mol) is a ratio of 1:1:1, Bi(NO 3 ) 3 ·5H 2 O and C 4 h 6 o 6 Add it into a reaction vessel filled with 3mol / L nitric acid solution and stir at constant temperature for 60min, then adjust pH=6 with ammonia water to obtain solution A, and mix NH 4 VO 3 Add it into hot water at 60°C to dissolve to obtain solution B. Mix the two solutions A and B, and stir at constant temperature for 45 minutes to obtain a bismuth vanadate solution.

[0032] The (2) step is the same as embodiment 1.

[0033] In step (3), m[BiVO 4 ]: m[SrFe 12 o 19 ]=100:5 strontium ferrite was added to the bismuth vanadate solution obtained above, and ultrasonically oscillated for 45 minutes to obta...

Embodiment 3

[0035] A kind of preparation method of the bismuth vanadate composite photocatalyst supported by strontium ferrite, with embodiment 1, wherein:

[0036] In step (1), with Bi(NO 3 ) 3 ·5H 2 The amount of species of O (mol): NH 4 VO 3 The amount of substance (mol): C 4 h 6 o 6 The amount of substance (mol) is a ratio of 1:1:3, Bi(NO 3 ) 3 ·5H 2 O and C 4 h 6 o 6 Add it into the reaction vessel filled with 4mol / L nitric acid solution and stir at constant temperature for 90min, then adjust the pH=5 with ammonia water to obtain solution A, mix NH 4 VO 3 Add it into hot water at 50°C to dissolve to obtain solution B. The two solutions A and B were mixed, and stirred at constant temperature for 60 minutes to obtain a bismuth vanadate solution.

[0037] The (2) step is the same as embodiment 1.

[0038] In step (3), m[BiVO 4 ]: m[SrFe 12 o 19 ] = 100:25 strontium ferrite, added to the bismuth vanadate solution obtained above, and ultrasonically oscillated for 60 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Band gap energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com