Mining plate-scraper control system and control method thereof

A technology of control system and scraper machine, which is applied in the direction of control system, motor generator control, motor starter, etc., which can solve the problems of not meeting the requirements of small underground space and large volume, and achieves easy heavy-duty start and small volume , Reduce the effect of equipment impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

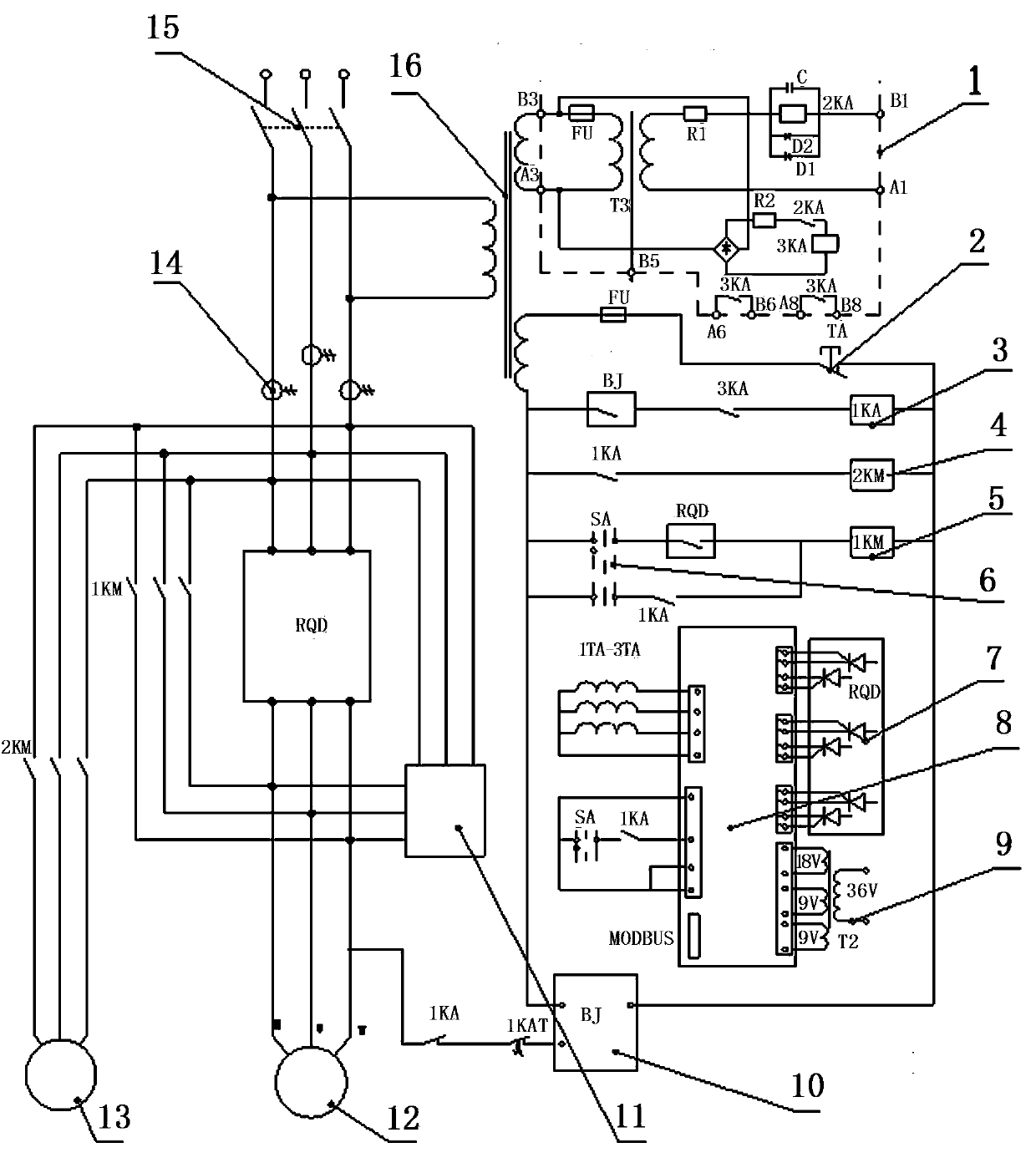

[0018] refer to figure 1 As shown, the present embodiment provides a mining scraper control system, including the main line connected to the three-phase power supply, the main power switch 15 set at one end of the main line, and the main motor of the controlled equipment set at the other end of the main line 12 and the auxiliary motor 13 of the controlled equipment, the speed reducer connected with the main motor 12 of the controlled equipment; it also includes a controllable soft start device RQD located on the main line; a control transformer 16 with a primary winding and a plurality of secondary windings , and the primary winding of the control transformer 16 is installed on the main line between the main power switch 15 and the controllable soft start device RQD; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com