Silane coupling agent-modified epoxy resin, and preparation method and application thereof

A silane coupling agent, epoxy resin technology, applied in epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problems of limiting the application of epoxy protective coatings, poor chemical resistance, poor aging resistance, etc. Achieve the effect of small strength drop, good chemical resistance and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

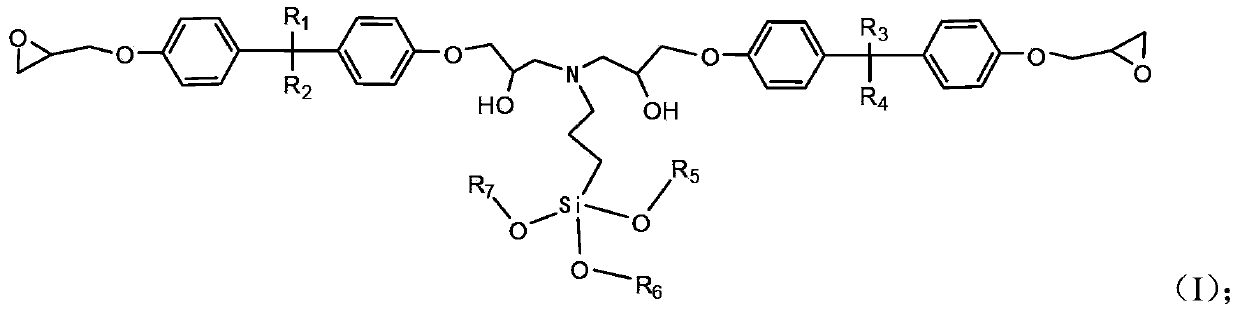

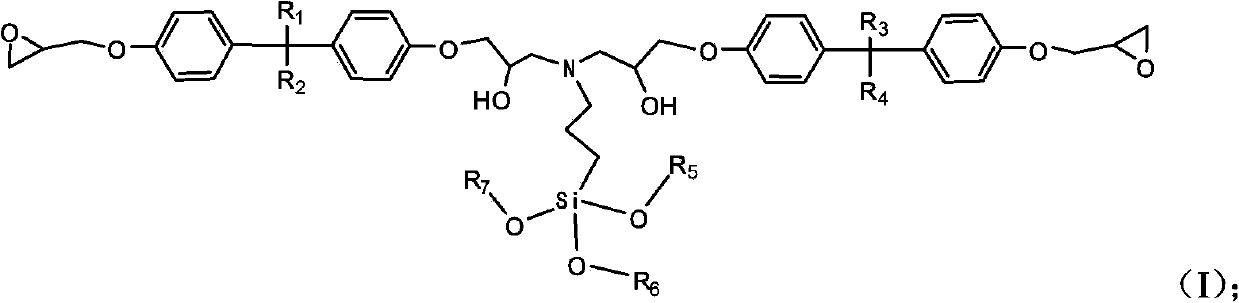

[0028] Prepare the epoxy resin modified by the silane coupling agent of structural formula (I) by each substituting group of table 1 respectively,

[0029]

[0030] Table 1 Structure of epoxy resin modified by silane coupling agent

[0031] code name

R1

R2

R3

R4

R5

R6

R7

SiEP01

CH 3

CH 3

CH 3

CH 3

C 2 h 5

C 2 h 5

C 2 h 5

SiEP02

CH 3

CH 3

H

H

C 2 h 5

C 2 h 5

C 2 h 5

SiEP03

H

H

H

H

C 2 h 5

C 2 h 5

C 2 h 5

SiEP04

CH 3

CH 3

CH 3

CH 3

CH 3

CH 3

CH 3

SiEP05

H

H

CH 3

CH 3

C 2 h 5

CH 3

CH 3

SiEP06

CH 3

H

H

CH 3

CH 3

C 2 h 5

C 2 h 5

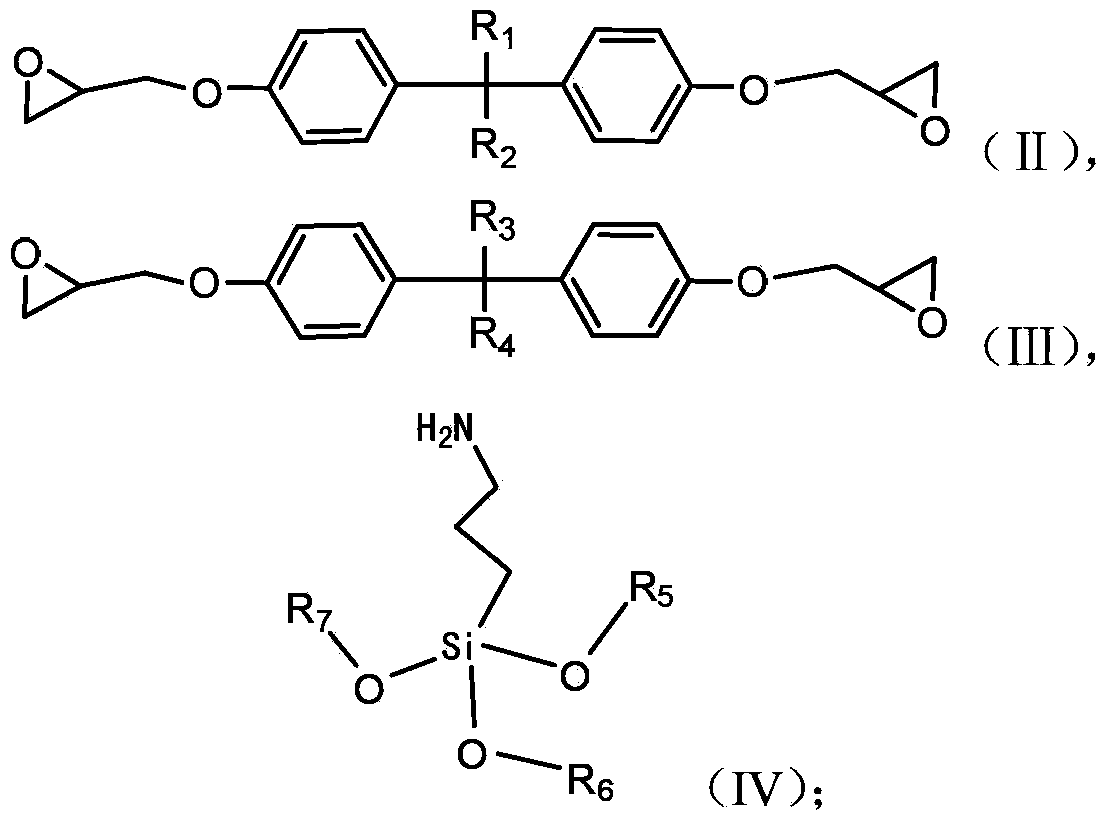

[0032] Its preparation method is: mix the epoxy resin monomer represented by the formula (II) with the molar ratio ...

Embodiment 2

[0043] According to the formula of Table 3, the epoxy protective paints numbered as sample 1 to sample 6, comparative example 1 and comparative example 2 were prepared respectively, and the following steps were adopted: modifying epoxy resin, diluent, functional filler, thixotropic agent, Add the dispersant, defoamer and pigment into the reaction kettle in order at room temperature, raise the temperature to 40-60°C and stir for 0.5-1.5 hours to prepare component A of epoxy protective coating; put the curing agent and accelerator at room temperature Put them into the reaction kettle in sequence, stir at room temperature for 0.5-1.5 hours, and prepare the B component of epoxy protective coating. Before use, mix components A and B according to the formula ratio and stir well to obtain the epoxy protective coating described herein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com