Porous diatomite filter material, and preparation method and applications thereof

A technology of diatomite and filter material, applied in the field of water treatment, can solve problems such as metal ion pollution and easy peeling off of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: Determination of the optimal conditions for the preparation of a porous diatomite filter material.

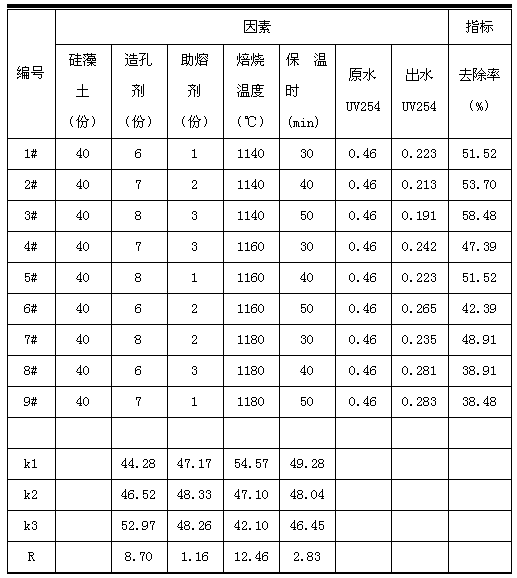

[0037] Taking the calcination temperature, the amount of pore-forming agent added, the amount of flux added and the holding time as factors, and the removal rate of UV254 as the evaluation index, a three-level and four-factor L 9 (3 4 ) Orthogonal experiments are as follows:

[0038] Orthogonal test factor level table

[0039]

[0040] Orthogonal test table

[0041]

[0042] From the extreme R analysis in the table, it can be seen that the influence on the removal rate of UV254: R3>R1>R4>R2, that is

[0043] The influence of each factor on the removal rate of UV254 is in order: roasting temperature, pore-forming agent addition, holding time, and flux addition. From this, it can be concluded that the optimal level conditions among the factors are: calcination temperature = 1140°C, 40 parts of diatomite, 8 parts of pore-forming agent, 2 parts of...

Embodiment 2

[0044] Embodiment 2: A kind of preparation method of porous diatomite filter material

[0045] Take 40 parts of diatomite raw material, add 8 parts of graphite powder pore-forming agent, 2 parts of calcium carbonate, stir evenly, add water as binder to make mud with certain plasticity, and then manually knead it into a diameter of 5- Small balls of about 10mm are dried in an oven at 105°C for 2 hours, taken out and crushed, and passed through a 10-35 mesh sieve to obtain a diatomite filter material with a particle size of 0.5mm to 2mm. Curve (heat up to 400°C for 20 minutes, 600°C for 20 minutes, 800°C for 20 minutes, then naturally heat up to 1140°C) at 1140°C, hold for 30 minutes, then let it cool down to room temperature naturally, take it out and rinse the surface with tap water Fine powder, put it in an oven for drying, take the dried filter material and pass it through a 35-mesh sieve (0.5mm). The required amount of porous diatomite filter material is sequentially proce...

Embodiment 3

[0047] Embodiment 3: Experimental research on the removal of suspended solids by porous diatom filter material soil

[0048]Kaolin and tap water are used to prepare raw water with a turbidity of about 16NTU. The porous diatomite filter material obtained in Example 2, quartz sand and anthracite are respectively used as filter materials. Tests with a model filter column show that, without adding any coagulation With the same agent, same filtration rate and influent turbidity, the effluent turbidity curve of porous diatomite filter material is obviously better than that of quartz sand filter material and anthracite filter material. When the filtration rate is 6m / h, the average turbidity removal rate of the porous diatomite filter material within 18 hours is 98.44%, which is 1.56 times that of anthracite and 1.65 times that of quartz sand; The average turbidity removal rate of diatomite filter material within 18 hours is 94.26%, which is 1.86 times that of anthracite and 2.23 time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com