Hydroponic units and systems

A hydroponic system and hydroponic technology, applied in cultivation, soilless cultivation, botanical equipment and methods, etc., can solve the problems of short lifespan, high labor cost and easy rust of PE film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] Hereinafter, referring to the drawings of different embodiments of the present invention, the technical solutions of the embodiments of the present invention will be described in detail and completely in an understandable manner. Apparently, the described embodiment is only a part but not all embodiments of the present invention. According to the embodiments described in the present invention, those skilled in the art can obtain other embodiments, which also fall within the protection scope of the present invention.

[0075] In order to solve the above-mentioned problems of conventional plant cultivation techniques, the present invention provides a hydroponic unit and system using artificial light.

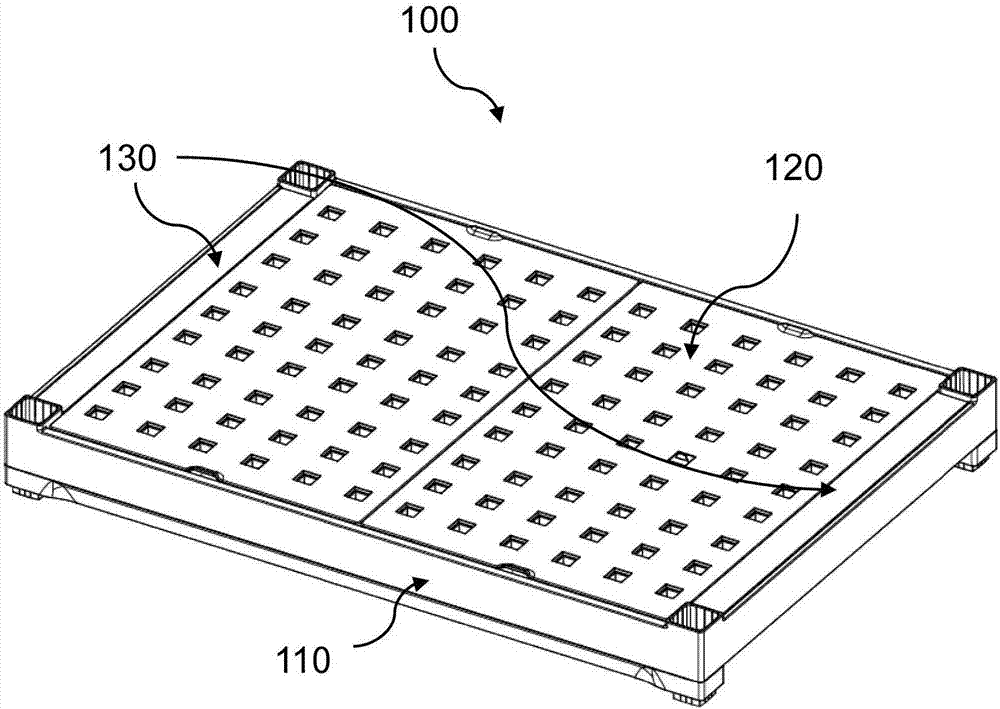

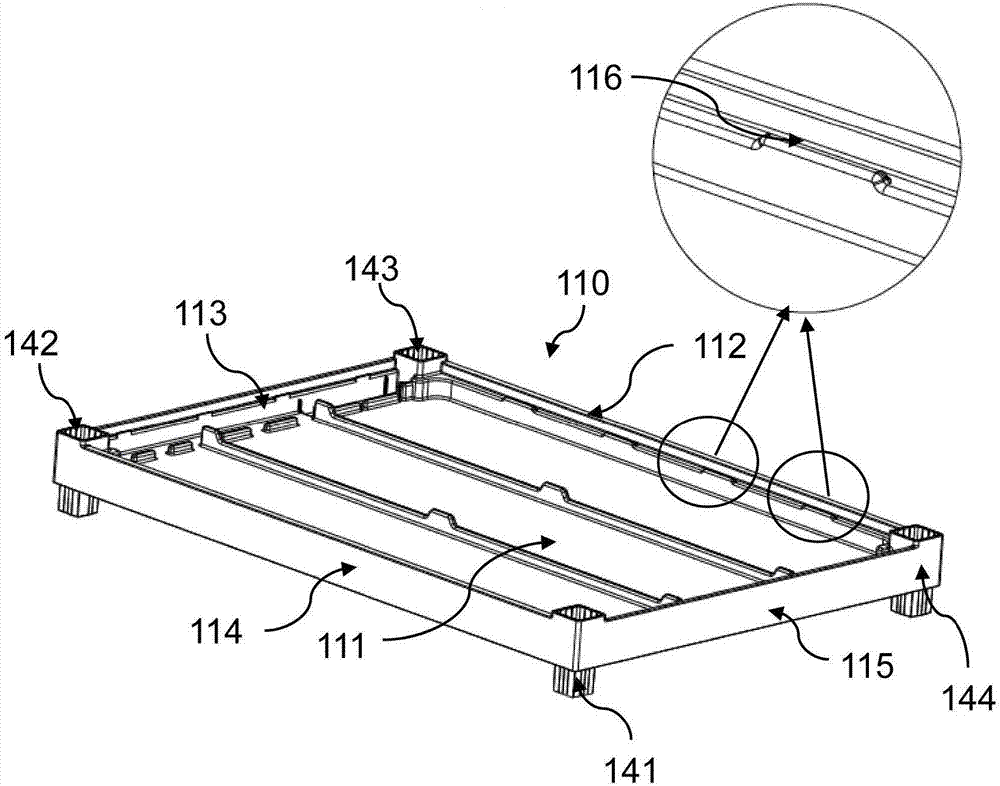

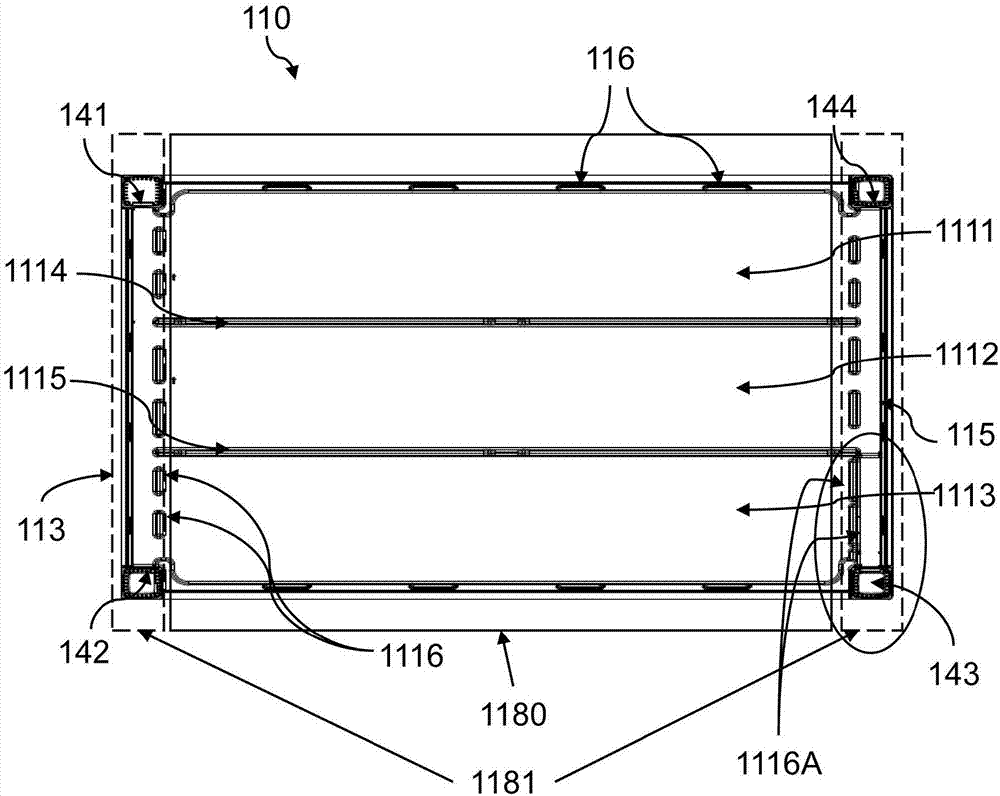

[0076] In a first aspect, the present invention provides a hydroponic unit. The hydroponic unit includes a water tank and a cultivation plate. The water tank is configured to provide a reservoir for the retention and flow of nutrient solution therein, and to provide growt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com