Filter system and method for collecting solid mineral grains from lean-phase superfine mineral suspension liquid

A filtration system and suspension technology, applied in the fields of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of easy blockage of filter element micropores, solid particles mixed into effluent, affecting service life, etc., which is conducive to timely and complete regeneration. , light weight, prolong service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

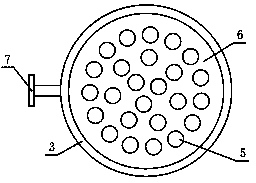

[0054] use figure 1 The filtration system shown is manually operated in batch operation mode, and the operation process of collecting molybdenite concentrate ore particles from dilute phase ultrafine molybdenite concentrate suspension includes raw water feeding, filtration separation, backwash cleaning and ore particle collection steps , the specific operation is as follows:

[0055] Raw water feed: open the feed control valve 17, delivery pump 21 and drain control valve 18, the dilute phase ultrafine molybdenite concentrate suspension in the raw water collection tank (not shown in the figure), that is, the raw water 31, passes through the raw water inlet pipe 13. Send it into the liquid inlet chamber 11 through the raw water inlet 7;

[0056] Filtration and separation: Under the action of pressure difference, the water phase in the raw water 31 flows from the outer surface of the filter element 5 through the micropores on the filter element 5, and enters the filter element 5...

Embodiment 1

[0060] A molybdenum company adopts such as figure 1 The filtration system shown treats the dilute-phase ultra-fine molybdenite concentrate suspension in the purification workshop and collects the molybdenite concentrate ore particles. The relevant parameters are as follows:

[0061] Filtration system: the cylinder diameter is 240mm, the cylinder height is 1.2m, there are 15 filter elements in the cylinder, and the length of a single filter element is 0.8m. 2 ;

[0062] Raw water: molybdenite concentrate hydrochloric acid leaching solution from the purification workshop, dehydrated by a belt vacuum filter to obtain dilute phase ultrafine molybdenite concentrate suspension, its solid content is 4.2%, stored in the raw water collection pool;

[0063] Saturation filtration time: 8.5h;

[0064] Saturation filtration pressure: 0.2MPa;

[0065] Set filter time: 2h;

[0066] Recoil pressure: 0.3MPa; Recoil time: 5min;

[0067]Implementation results: treatment capacity: raw water ...

specific Embodiment approach 2

[0079] use image 3 The filtration system shown is in automatic online operation mode, and the operation process of collecting molybdenum concentrate ore particles from dilute phase ultrafine molybdenite concentrate suspension includes raw water feeding, filtration separation, backwash cleaning and ore particle collection steps , the specific operation is as follows:

[0080] Raw water feed: designate filter IV as a standby switching filter; electrical control system 29 controls the opening of feed control valve 17, delivery pump 21 and drain control valve 18 of filter I, raw water collection tank (not shown in the figure) The dilute-phase ultrafine molybdenite concentrate suspension in the molybdenum concentrate, that is, the raw water 31, is sent into the liquid inlet chamber 11 through the raw water inlet 7 through the raw water inlet main pipe 22 and the raw water inlet pipe 13; similarly, the electric control system 29 controls the dilute-phase ultrafine molybdenite conce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com