Manufacturing method of large-caliber wear-resistant and corrosion-resistant ternary composite pipe

A ternary composite and manufacturing method technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of pipe straightness and roundness deformation, steel pipe perforation, etc., to achieve reduced deformation, tight and smooth combination The effect of leveling, ensuring strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

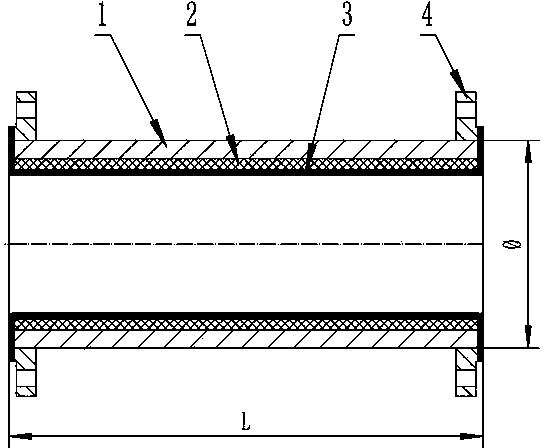

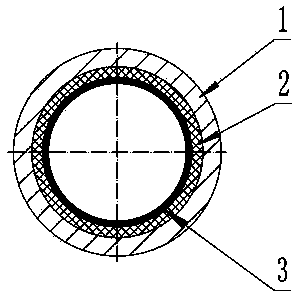

[0035] Example 1: This method is used to make DN1000 length 6000 ternary composite pipes (unspecified length units are mm, the same below)

[0036] a. Application of self-propagating high-temperature centrifugal synthesis reaction (SHS) to fabricate large-diameter ceramic composite steel pipes

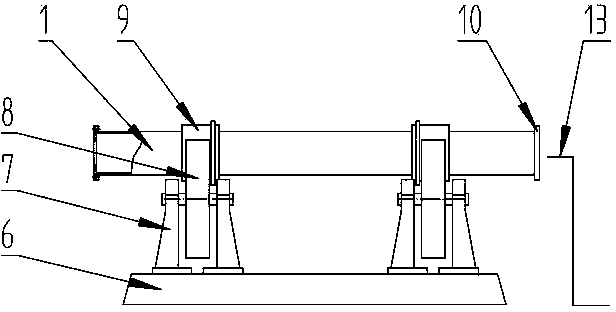

[0037] This large-diameter steel pipe is made of steel plate, with an outer diameter of 1020, a wall thickness of 12, and a length of 2000. The butt joint is automatically welded, and the roundness error and linear reading error are not greater than 2. (like Figure 7 ), the steel pipe butt joint is placed at the butt joint gap between the upper and lower casings.

[0038] Install the cover at both ends, the cover is closely attached to the steel pipe, and fixed firmly with bolts.

[0039] Prepare thermite, with the ratio of iron oxide powder 56%, aluminum powder 21%, zirconia powder 8%, titanium oxide powder 4%, silicon oxide powder 3%, aluminum oxide powder 3%, boron oxide 5%, etc....

Embodiment 2

[0045] Example 2: This method is used to make a ternary composite pipe with a length of DN600 and a length of 4000 (unspecified length units are mm, the same below)

[0046] a. Application of self-propagating high-temperature centrifugal synthesis reaction (SHS) to fabricate large-diameter ceramic composite steel pipes

[0047] This large-diameter steel pipe is made of steel plate, with an outer diameter of 630mm, a wall thickness of 12mm, and a length of 2000mm. (like Figure 7 ), the steel pipe butt joint is placed at the butt joint gap between the upper and lower casings.

[0048] Install the cover at both ends, the cover is closely attached to the steel pipe, and fixed firmly with bolts.

[0049] Prepare thermite, with the ratio of iron oxide powder 56%, aluminum powder 19%, zirconia powder 8%, titanium oxide powder 5%, silicon oxide powder 3%, aluminum oxide powder 4%, boron oxide 5%, etc. Prepare 86kg of reaction raw materials, mix them evenly, add them into a large-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com