Environmentally-friendly metal polishing agent and preparation method thereof

A polishing agent and metal technology, which is applied in the field of environment-friendly metal surface cleaners and its preparation, can solve the problems of unfriendly environment, narrow metal types, low unit output, etc., achieve improved anti-oxidation and anti-corrosion performance, simple preparation method, The effect of enhancing the finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

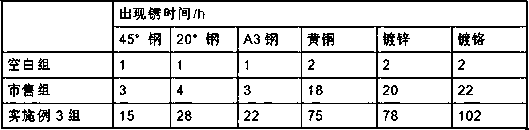

Examples

Embodiment 1

[0011] An environmentally friendly metal polishing agent, comprising the following raw materials in parts by weight: 2 parts of vegetable oleic acid, 5 parts of cocoyl glucoside, 5 parts of sodium dodecylbenzenesulfonate, 20 parts of mineral oil, imidazoline quaternary ammonium 8 parts of salt, 2 parts of triethanolamine oleate, 50 parts of silicon micropowder, 5 parts of polyethylene glycol, 15 parts of layered crystal sodium disilicate, and 80 parts of deionized water.

[0012] The preparation method of the environment-friendly metal polishing agent of this embodiment is to mix vegetable oleic acid, cocoyl glucoside, sodium dodecylbenzenesulfonate, mineral oil, imidazoline quaternary ammonium salt, oleic acid triethanolamine, silicon micropowder, polyethylene glycol Alcohol and layered crystalline sodium disilicate are sequentially added to deionized water, stirred and heated to 60°C, and mixed evenly to obtain an environmentally friendly metal polishing agent.

[0013]

Embodiment 2

[0015] An environment-friendly metal polishing agent, comprising the following raw materials in parts by weight: 10 parts of vegetable oleic acid, 8 parts of cocoyl glucoside, 10 parts of sodium dodecylbenzenesulfonate, 30 parts of mineral oil, imidazoline quaternary ammonium 13 parts of salt, 5 parts of triethanolamine oleate, 80 parts of silicon micropowder, 10 parts of polyethylene glycol, 20 parts of layered crystalline sodium disilicate, and 100 parts of deionized water.

[0016] The preparation method of the environment-friendly metal polishing agent of this embodiment is to mix vegetable oleic acid, cocoyl glucoside, sodium dodecylbenzenesulfonate, mineral oil, imidazoline quaternary ammonium salt, oleic acid triethanolamine, silicon micropowder, polyethylene glycol Alcohol and layered crystalline sodium disilicate are sequentially added to deionized water, stirred and heated to 80°C, and mixed evenly to obtain an environmentally friendly metal polishing agent.

[0017]...

Embodiment 3

[0019] An environmentally friendly metal polishing agent, comprising the following raw materials in parts by weight: 2 to 10 parts of vegetable oleic acid, 7 parts of cocoyl glucoside, 8 parts of sodium dodecylbenzenesulfonate, 26 parts of mineral oil, imidazoline 11 parts of quaternary ammonium salt, 3 parts of triethanolamine oleate, 65 parts of silicon micropowder, 7 parts of polyethylene glycol, 19 parts of layered crystalline sodium disilicate, and 88 parts of deionized water.

[0020] The preparation method of the environment-friendly metal polishing agent of this embodiment is to mix vegetable oleic acid, cocoyl glucoside, sodium dodecylbenzenesulfonate, mineral oil, imidazoline quaternary ammonium salt, oleic acid triethanolamine, silicon micropowder, polyethylene glycol Alcohol and layered crystalline sodium disilicate are sequentially added to deionized water, stirred and heated to 70°C, and mixed evenly to obtain an environmentally friendly metal polishing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com