Composition used for rare earth catalyst, rare earth catalyst and its application

A rare earth compound and rare earth catalyst technology, applied in the field of rare earth catalyst compositions, can solve the problems of poor stability, high gel content of diolefin polymers, difficult control of molecular weight and molecular weight distribution, etc., and achieve stable quality and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Catalyst preparation:

[0049] 300ml of NdCl 3 ·3C 2 h 5 OH / hexane dispersion (Nd content: 6 mmol) was added to the aging reactor, then 12 g of isoprene was added, and then 300 ml of triisobutylaluminum (Al content was 168 mmol) was added under stirring conditions, and the temperature was continued at room temperature for 20 ℃ for 1 hour to obtain neodymium-based rare earth catalyst C1. The degree of polymerization of the isoprene prepolymer in the catalyst was 268.

[0050] Solution polymerization of isoprene using prepared catalyst C1:

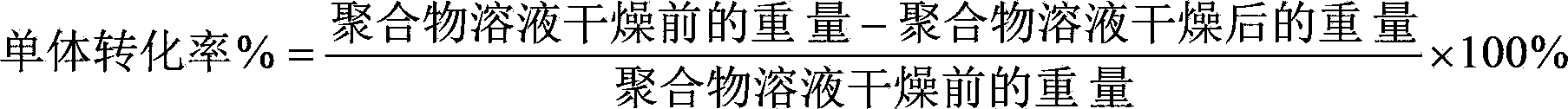

[0051] Under the protection of nitrogen, 400 g of isoprene, 1491 g of cyclohexane and 160 ml of catalyst C1 were successively added into a 5 L polymerization kettle, and the monomer concentration was 20% by weight. After reacting at 30° C. for 1 hour, the polymer solution was discharged from the kettle and 2,6-di-tert-butylhydroquinone methanol solution was added to terminate the reaction. The monomer conversion rate is 80%, the...

Embodiment 2

[0053] Catalyst preparation:

[0054] 300ml of NdCl 3 ·3C 3 h 7 Add OH / hexane dispersion (Nd content is 6mmol) into the aging reactor, then add 1.1mol / l isoprene hexane solution 210ml, then add triethylaluminum 90ml (Al content is 90mmol ), and continue to stand at 50° C. for 0.5 hour to obtain the neodymium-based rare earth catalyst C2. The degree of polymerization of the isoprene prepolymer in the catalyst was 380.

[0055] Solution polymerization of isoprene using prepared catalyst C2:

[0056] Under the protection of nitrogen, 350 g of isoprene, 1907 g of hexane and 112 ml of catalyst C2 were sequentially added into a 5 L polymerization kettle, and the monomer concentration was 15% by weight. After reacting at 50° C. for 1 hour, the polymer solution was released from the kettle and 2,6-di-tert-butylhydroquinone methanol solution was added to terminate the reaction. The monomer conversion rate was 91%, the cis 1,4-structure content in the polymer was 96.0%, the Mooney...

Embodiment 3

[0058] Catalyst preparation:

[0059] 200ml of NdCl 3 2THF / hexane dispersion (with Nd content of 5mmol) was added to the aging reactor, then 20g of isoprene was added, and then 160ml of triethylaluminum (with an Al content of 80mmol) and 410g of hexane were added under stirring conditions, Continue to stand at room temperature 15° C. for 1.5 hours to obtain neodymium-based rare earth catalyst C3. The degree of polymerization of the isoprene prepolymer in the catalyst was 750.

[0060] Solution polymerization of isoprene using prepared catalyst C3:

[0061] Under the protection of nitrogen, 250 g of isoprene, 2148 g of hexane and 150 ml of catalyst C3 were successively added into a 5 L polymerization kettle, and the monomer concentration was 10% by weight. After reacting at 10° C. for 3.5 hours, the polymer solution was released from the kettle and 2,6-di-tert-butylhydroquinone methanol solution was added to terminate the reaction. The monomer conversion rate was 89%, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com