(lino3–kno3–kno2–ca(no3)2) quaternary nitric acid eutectic salt and its use

A technology of eutectic salt and nitric acid, applied in electrical components, delayed action cells, electrochemical generators, etc., can solve the problems of low temperature limit of liquid water, difficulty in meeting heat transfer requirements, expensive heat transfer medium, etc., to achieve Solve the problem of instability, the effect of wide working temperature range and low melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A kind of quaternary nitric acid eutectic salt, the component that it comprises and component mass percent are as follows: LiNO 3 , 15%; KNO 3 , 10%; KNO 2 , 60%; Ca(NO 3 ) 2 , 15%.

[0055] The raw materials used include LiNO 3 , KNO 3 , KNO 2 and Ca(NO 3 ) 2 4H 2 O, raw material purity>99%. Weigh 0.75g LiNO 3 , 0.5g KNO 3 , 3.0g KNO 2 and 1.08g Ca(NO 3 ) 2 4H 2 O, measure 100ml of deionized water; pour the weighed components into deionized water, stir evenly and ultrasonically dissolve; heat the mixed solution to 100°C for distillation; put the solute left over from distillation into high temperature In the furnace, melt at 300°C for 16 hours, then cool to room temperature with the furnace; grind the cooled solid into powder, sieve, and then seal and store to obtain the required quaternary nitric acid eutectic salt.

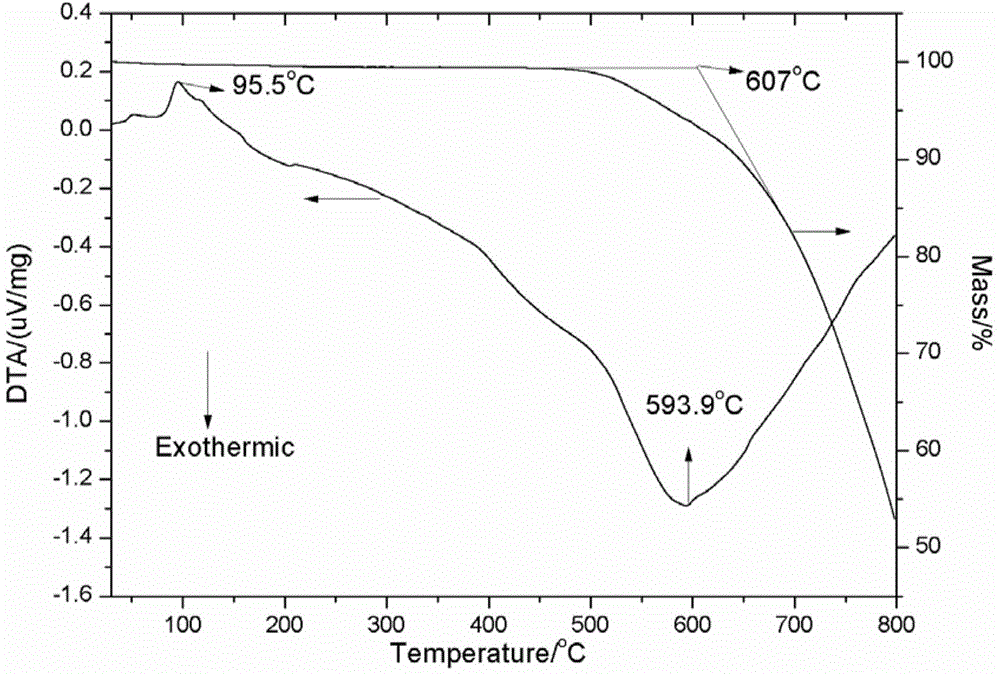

[0056] Using STA449F3DSC / DTA-TG synchronous thermal analyzer, the DTA-TG test was performed on the quaternary nitric acid eutectic salt...

Embodiment 2

[0058] A kind of quaternary nitric acid eutectic salt, the component that it comprises and component mass percent are as follows: LiNO 3 , 20%; KNO 3 , 15%; KNO 2 , 50%; Ca(NO 3 ) 2 , 15%. Refer to Example 1 for the specific preparation method.

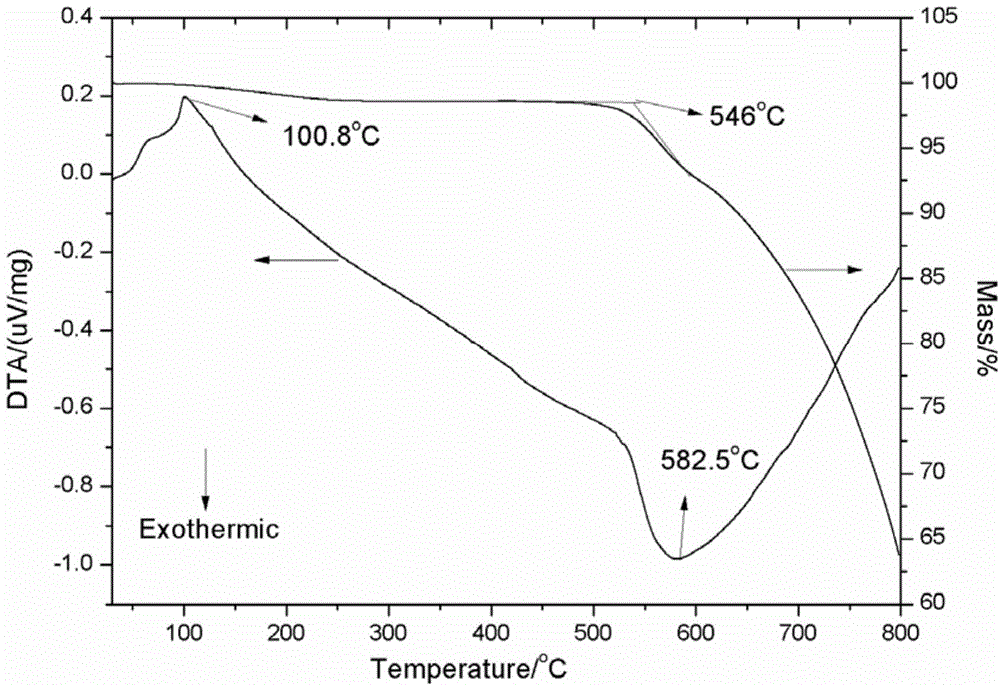

[0059] Using STA449F3DSC / DTA-TG synchronous thermal analyzer, the DTA-TG test was performed on the quaternary nitric acid eutectic salt prepared in this example at a heating rate of 10K / min. The DTA-TG curve obtained from the test is as follows figure 2 shown. The test results show that the exothermic peak start point of the quaternary nitric acid eutectic salt is around 92.5°C (that is, the melting point of the molten salt), and the peak value is 100.8°C; the start point of the thermogravimetric weight loss is around 546°C. Therefore, the working range of the molten salt is 92.5-546°C.

Embodiment 3

[0061] A kind of quaternary nitric acid eutectic salt, the component that it comprises and component mass percent are as follows: LiNO 3 , 25%; KNO 3 , 20%; KNO 2 , 40%; Ca(NO 3 ) 2 , 15%. Refer to Example 1 for the specific preparation method.

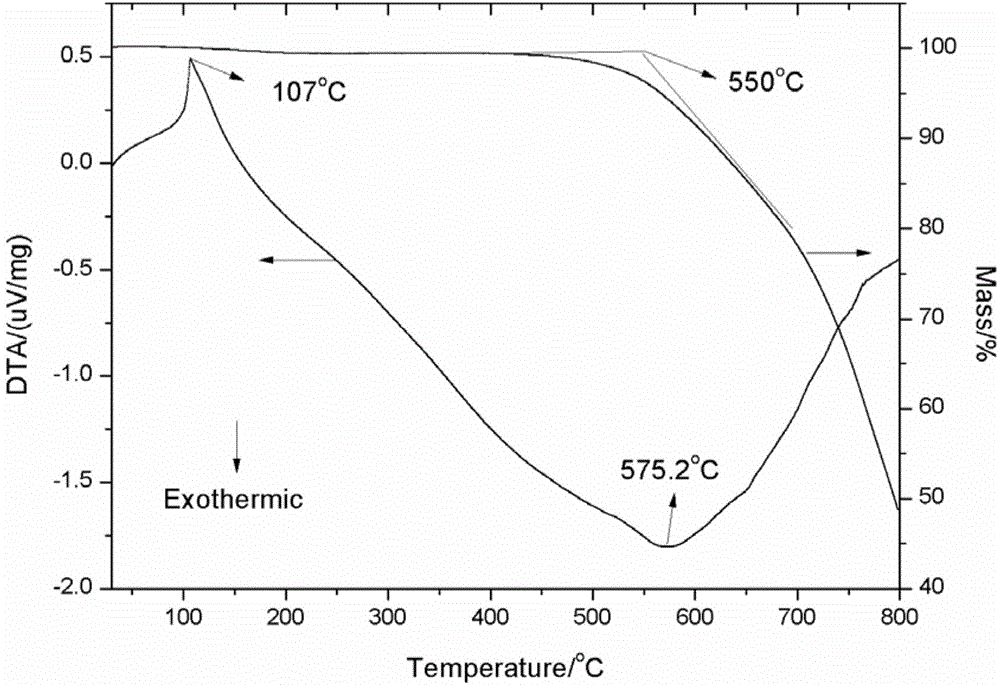

[0062] Using STA449F3DSC / DTA-TG synchronous thermal analyzer, the DTA-TG test was performed on the quaternary nitric acid eutectic salt prepared in this example at a heating rate of 10K / min. The DTA-TG curve obtained from the test is as follows image 3 shown. The test results show that the exothermic peak start point of the quaternary nitric acid eutectic salt is around 102.5°C (that is, the melting point of the molten salt), and the peak value is 107°C; the start point of the thermogravimetric weight loss is around 550°C. Therefore, the working range of the molten salt is 102.5-550°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal stability | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com