Fluorine-containing epoxy acrylate prepolymer for UV coating and preparation method thereof

A technology of epoxy acrylate and prepolymer, which is applied in the field of coatings, can solve the problems of further improvement of tensile strength, and achieve the effects of eliminating phase separation, improving related performance, and reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

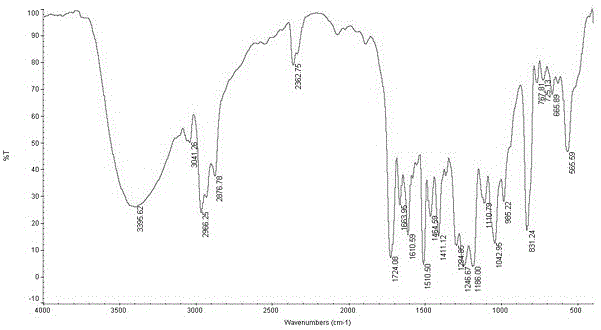

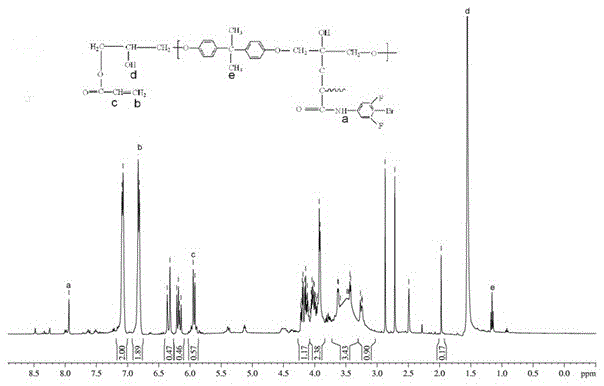

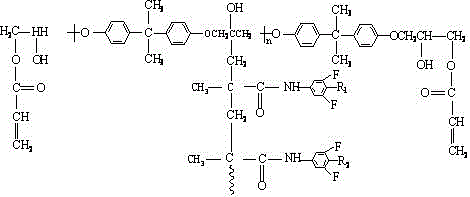

Method used

Image

Examples

Embodiment 1

[0033] Dissolve 5mmol (2.26g) of epoxy resin (E44) in 10g of ethylene glycol monomethyl ether, and add 1.4 The mixed solution of 4-bromo-3,5-difluorophenylmethacrylamide and 10g ethylene glycol monomethyl ether was then heated to 90°C and reacted for 2h, and the ethylene glycol monomethyl ether was distilled off under reduced pressure, and the obtained The product was extracted and washed with ethanol (50ml×2), and the ethanol layer was distilled off under reduced pressure to remove ethanol;

[0034] Get 50g of the previous step product, 5g of triethylamine, and 0.5g of hydroquinone into a four-necked flask, pass N 2 , slowly drop 0.36g of acrylic acid (2h dropwise), heat up to 60 ° C for a period of time, measure the acid value of the reactant, when the acid value is less than 8mgKOH / g, it is the end point;

[0035] With 10wt% Na 2 CO 3 The aqueous solution was washed 4 times, then dissolved in ether, and then washed with anhydrous Na 2 SO 4 Dry and evaporate ether to ob...

Embodiment 2

[0042] Dissolve 5mmol (2.26g) of epoxy resin (E44) in 10g of ethylene glycol monomethyl ether, and add dropwise A mixed solution of 2.8g of 3,5-difluorophenyl methacrylamide and 10g of ethylene glycol monomethyl ether, then heated up to 60°C, reacted for 4h, removed ethylene glycol monomethyl ether by distillation under reduced pressure, and used the obtained product Ethanol (50ml×2) was extracted and washed, and the ethanol layer was distilled off under reduced pressure to remove ethanol;

[0043] Take 50g of the product from the previous step, 4g of sodium hydroxide, and 0.4g of p-hydroxyanisole into a four-necked flask, blow nitrogen, slowly add 0.72g of acrylic acid dropwise (2.5h to complete the drop), and raise the temperature to 70°C for a period of time. Measure the acid value of the reactant, when the acid value is less than 8mgKOH / g, it is the end point;

[0044] With 10wt% Na 2 CO 3 The aqueous solution was washed 5 times, then dissolved in ether, and then washed...

Embodiment 3

[0047] Dissolve 5mmol (2.26g) of epoxy resin (E51) in 10g of ethylene glycol monomethyl ether, and add dropwise A mixed solution of 4.2g 1,3,5-difluorophenylmethacrylamide and 10g ethylene glycol monomethyl ether, then heated up to 80°C, reacted for 3h, removed ethylene glycol monomethyl ether by distillation under reduced pressure, and obtained The product was extracted and washed with ethanol (50ml×2), and the ethanol was removed by distillation under reduced pressure;

[0048] Take 50g of the product from the previous step, 2g of sodium bicarbonate, and 0.9g of p-hydroxyanisole into a four-necked flask, pass nitrogen gas, slowly add 1.8g of acrylic acid dropwise (the dropwise addition is completed in 3 hours), raise the temperature to 80°C for a period of time, and measure The acid value of the reactant, when the acid value is less than 8mgKOH / g, is the end point;

[0049] With 10wt% Na 2 CO 3 The aqueous solution was washed 5 times, then dissolved in ether, and then was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com