Wood-plastic composite section and preparation method thereof

A wood-plastic composite material and wood fiber material technology, applied in the direction of the base frame, etc., can solve the problems of large smoke production and addition amount, complicated operation, difficult to mix evenly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

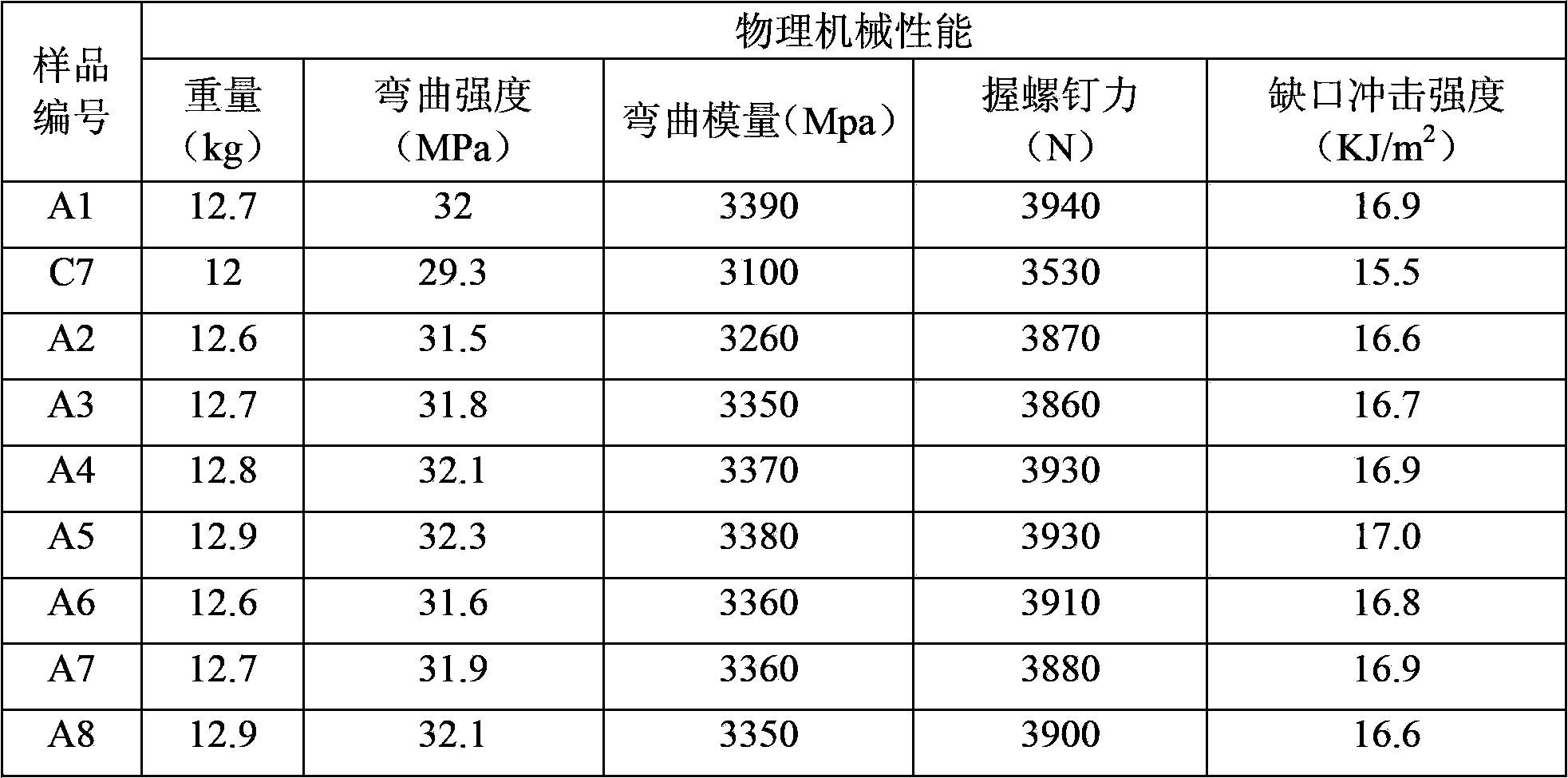

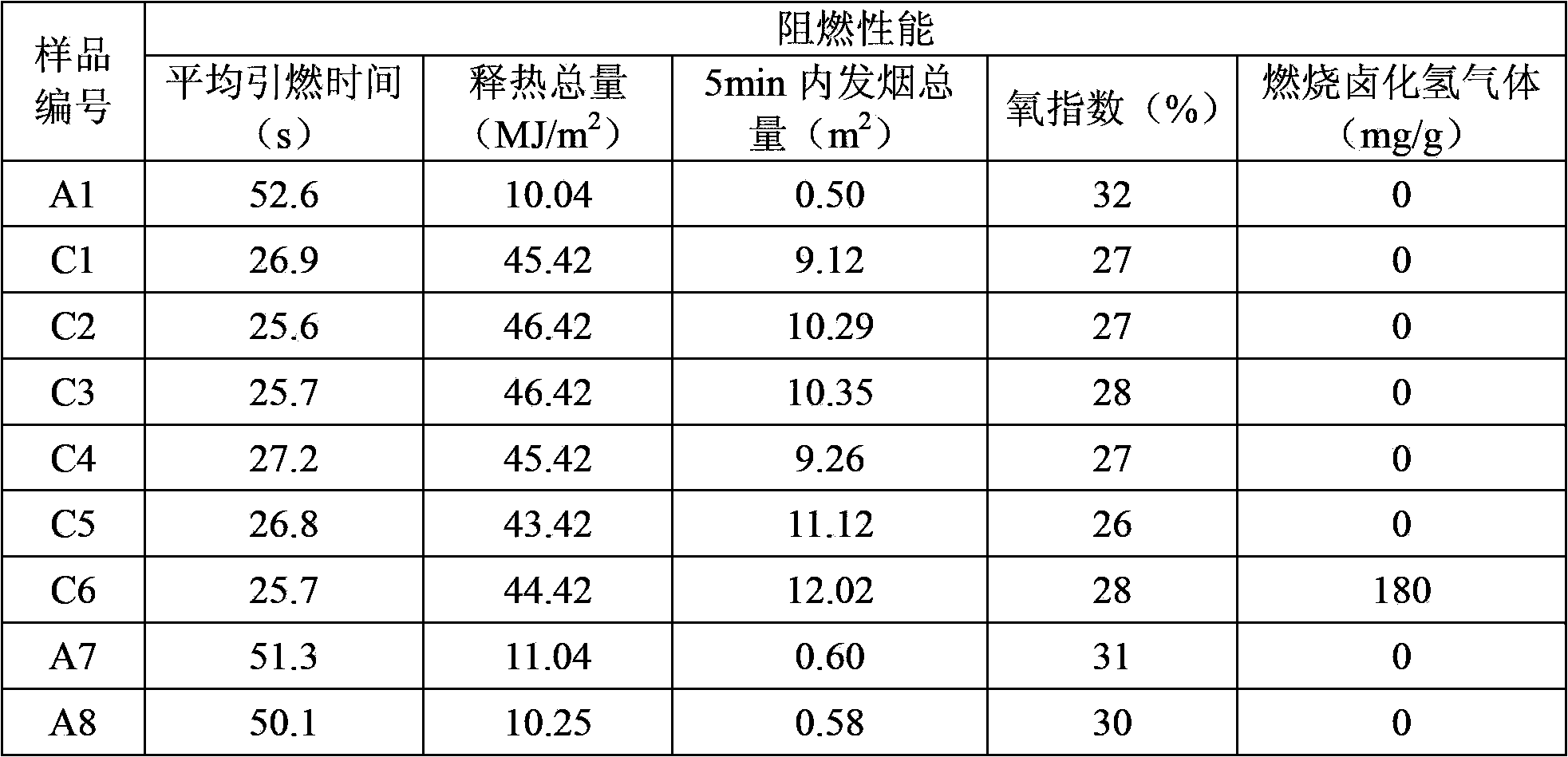

Examples

preparation example Construction

[0030] More preferably, described lightweight material is biomass-based polyurethane foam, and the preparation method of described biomass-based polyurethane foam comprises the following steps:

[0031] (1) At 100-135°C, make straw lignin materials, polyols and acidic catalysts undergo a first contact reaction for 1-4 hours, and then add starch for a second contact reaction to obtain lignin modified products;

[0032] (2) Evenly mix the modified lignin, polyether polyol, amine catalyst and blowing agent, then add isocyanate according to the isocyanate index of 1-1.4 for the third contact reaction, and the third contact reaction The resulting product was cured.

[0033] In the present invention, the term "isocyanate index" refers to the ratio of isocyanate equivalents to polyol equivalents, indicating the degree of excess isocyanate in the polyurethane formulation, and the isocyanate equivalents refer to the moles of isocyanate in isocyanate, The polyol equivalents refer to the ...

Embodiment 1

[0057] (1) Preparation of shell

[0058] 100 parts by weight of pentaerythritol and 85 parts by weight of phosphoric acid were mixed, and stirred and reacted at 140° C. for 1 hour, and then 185 parts by weight of polyether polyol (polyether polyols purchased from Beijing Bailing Qingyue Polyurethane Factory) were added to the reaction product. Polyol 4110), 160 parts by weight of ammonium polyphosphate (purchased from Beijing Lianchuang Chemical Co., Ltd., the degree of polymerization is 1500) and 150 parts by weight of melamine, and stirred and reacted at 140 ° C for 0.5 hours to prepare a flame retardant .

[0059]100 parts by weight of plastic (polypropylene, with a weight-average molecular weight of 250,000), 100 parts by weight of lignocellulosic material (wood flour, with a particle size of 100 mesh), 80 parts by weight of the above-mentioned flame retardant, and 5 parts by weight of plasticizer agent (epoxidized soybean oil), 3 parts by weight of antioxidant (antioxida...

Embodiment 2

[0079] Profile A2 was prepared according to the method of Example 1, except that in step (2), 110 parts by weight of corn stalks (particle size 80-120 mesh), 100 parts by weight of polyethylene glycol, 30 parts by weight of Glycerin and 1.5 parts by weight of sulfuric acid (98% concentrated sulfuric acid) were mixed and reacted at 120°C for 2.5 hours to prepare lignin-modified products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com