Flexible transparent conductive material of topological insulator and preparation method and application thereof

A topological insulator, flexible technology, applied in conductive layers on insulating carriers, cable/conductor manufacturing, nanotechnology for materials and surface science, etc. Achieve excellent mechanical properties, high light transmittance, and high electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Example 1: Preparation of a flexible transparent conductive film with a regular network structure of topological insulators

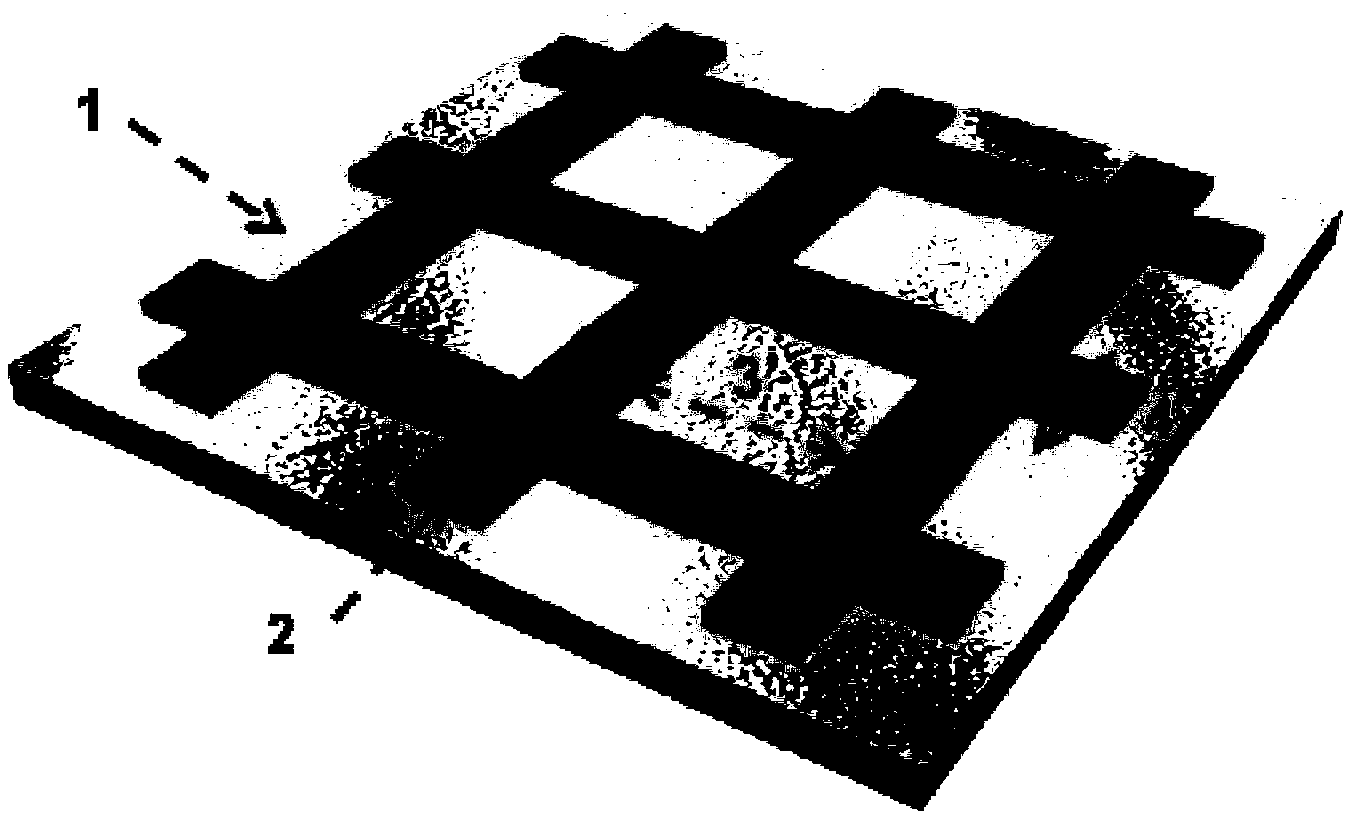

[0081] 1) Fluorphlogopite KMg with a clean surface and a thickness of 30 μm was obtained by mechanical exfoliation 3 (AlSi 3 0 10 )F 2 ,by figure 1 The square carbon-free copper mesh shown is the mask plate (the aperture size is 160 × 160 μm, and the rib width is 30 μm. The dark area is covered with Bi 2 Se 3 film with a network structure, the light-colored part is the fluorine phlogopite substrate), plasma etching was carried out in the air atmosphere, the etching power was 90W, and the time was 15min to obtain a patterned fluorine phlogopite substrate;

[0082] The structure of the carbon-free copper mesh is as follows figure 1 As shown in No. 2, the specification is 1.2cm×1.2cm, mesh ( figure 1 No. 3) The side lengths are 50μm, 60μm, 90μm, and 160μm in four specifications, and the rib width ( figure 1 No. 4) are all 30μm;

[0083] 2) ...

Embodiment 2

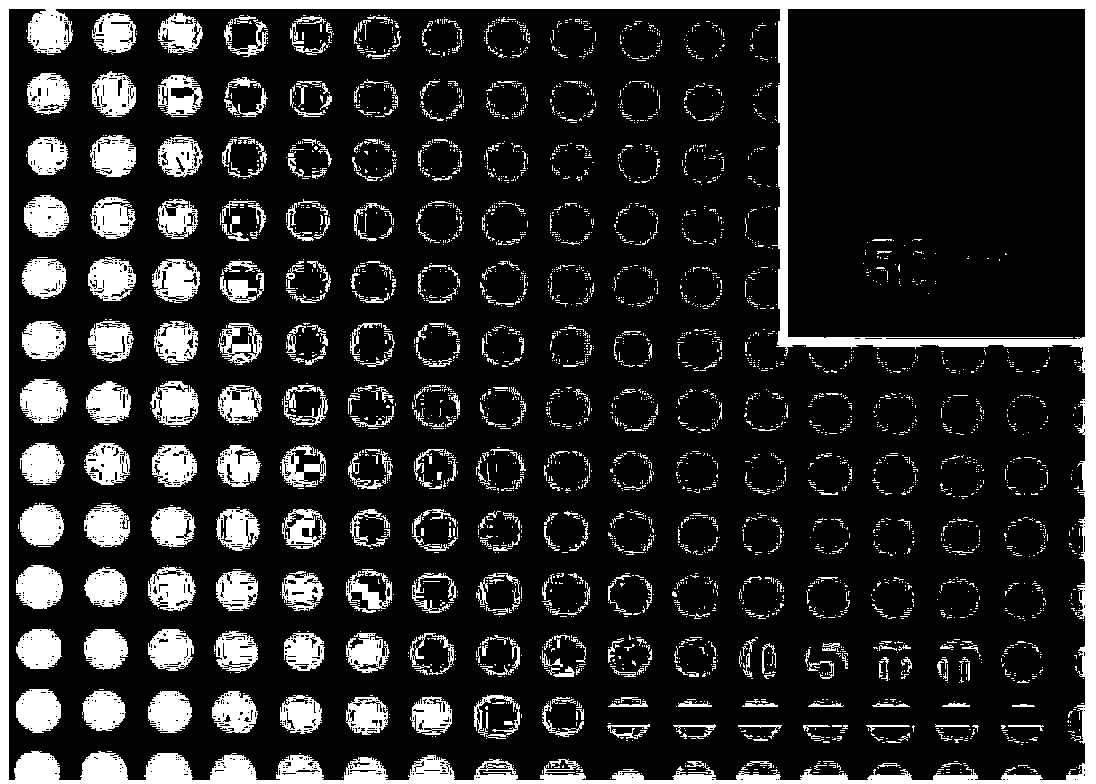

[0115] Example 2: Preparation of topological insulator random network structure flexible transparent conductive film

[0116] 1) Add 5 μL of poly-L-lysine solution with a ratio of 0.1 g:1000 mL of poly-L-lysine to water to 1 mL of Au sol with a diameter of 20 nm and mix well, then add drop-wise to clean Si (100 ) on the base, make it dry naturally, and complete the functional modification of the base;

[0117] 2) Set Bi 2 Te 3 Bulk crystals (produced by Alfa Aesar, with a purity of 99.999%) were ground into powder as a volatilization source and placed in the middle of the quartz tube, that is, in the middle of the gas flow direction. The functionally modified substrate obtained in step 1) was placed below the gas flow direction and 11 cm away from the volatilization source -15cm position, then place the quartz tube in the tube furnace;

[0118] Start the vacuum pump, pump the quartz tube to a base pressure of 100mTorr (1Torr=1mmHg=133.3Pa), turn off the vacuum pump and open...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com