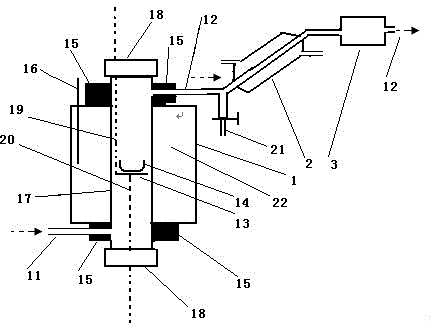

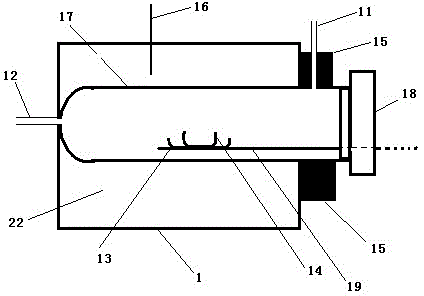

Analysis sample injection apparatus and method for making element form volatile by using organic matter cracking

A technology of sampling device and cracking device, which is applied in the field of instrument analysis and can solve the problems of increasing the cost of analysis and testing, affecting accuracy, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

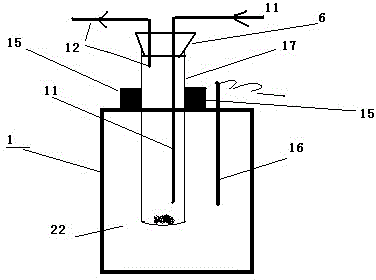

[0138] Embodiment 1: Arsenic content analysis in rice

[0139] In a 20 ml quartz test tube, accurately add 10 mg of rice sample, then put a rubber stopper with inlet and outlet of carrier gas (argon, flow rate 300 ml / min) on it and plug the test tube mouth tightly. The carrier gas outlet pipe carrying elemental volatiles is connected in series with a U-shaped condenser (to remove water and organic volatiles) and a plastic tube with quartz wool (to remove particulate matter). The purified carrier gas and atomic fluorescence atoms At this time, the atomic fluorescence atomizer is also connected with a hydrogen generator (hydrogen generation rate: 450 ml / min), so as to provide a hydrogen source for the normal ignition of the atomizer. And the carrier gas inlet is connected with the atomic fluorescence carrier gas supply pipe. When the device is connected and running stably, immediately insert the test tube into the thermostatic furnace that has been heated to 550°C in advanc...

Embodiment 2

[0140] Embodiment 2: the analysis of cadmium in spinach

[0141] The full set of apparatus and parameters of the preferred embodiment 2 were used to determine the cadmium content in spinach. In a quartz crucible (10 ml), accurately add 20 mg of spinach sample, because the vegetable itself is an organic matrix sample, so do not add any additional organic matter. Then put the crucible into the constant temperature furnace that has been heated to 550°C in advance under the supply of carrier gas, and start the instrument at the same time to start the atomic fluorescence measurement. By comparing with another spinach surface sample GBW10015 to make an appearance standard curve, the measurement result is 88ppb. However, the normal nitric acid-perchloric acid method was used to digest the sample, and the cadmium in the sample was measured by hydride to generate adispersive atomic fluorescence. The result was 83ppb, which shows that this method is in good agreement with the tradit...

Embodiment 3

[0142] Embodiment 3: the analysis of lead in fish gill

[0143] The full set of apparatus and parameters of the preferred example 4 were used to determine the cadmium content in fish gills. In a 10 ml quartz crucible, accurately add 10 mg of the fish gill sample, because the sample itself is an organic matrix sample, so do not add any more organic matter. Then put the crucible through the integrated device of the crucible support bracket and rubber sealing plug under the carrier gas, and quickly put it into the constant temperature furnace that has been heated to 600 ℃ in advance, and start the instrument at the same time to start the atomic fluorescence measurement. (Argon gas flow rate is 500 ml / min, hydrogen generator flow rate is 400 ml / min). Measure the content of lead in fish gills according to the standard addition method, and the assay result is 60ppb. However, the normal nitric acid-perchloric acid method was used to digest the sample and the lead content in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com